Rainbow Electronics MAX782 User Manual

Page 13

MAX782

Triple-Output Power-Supply

Controller for Notebook Computers

______________________________________________________________________________________

13

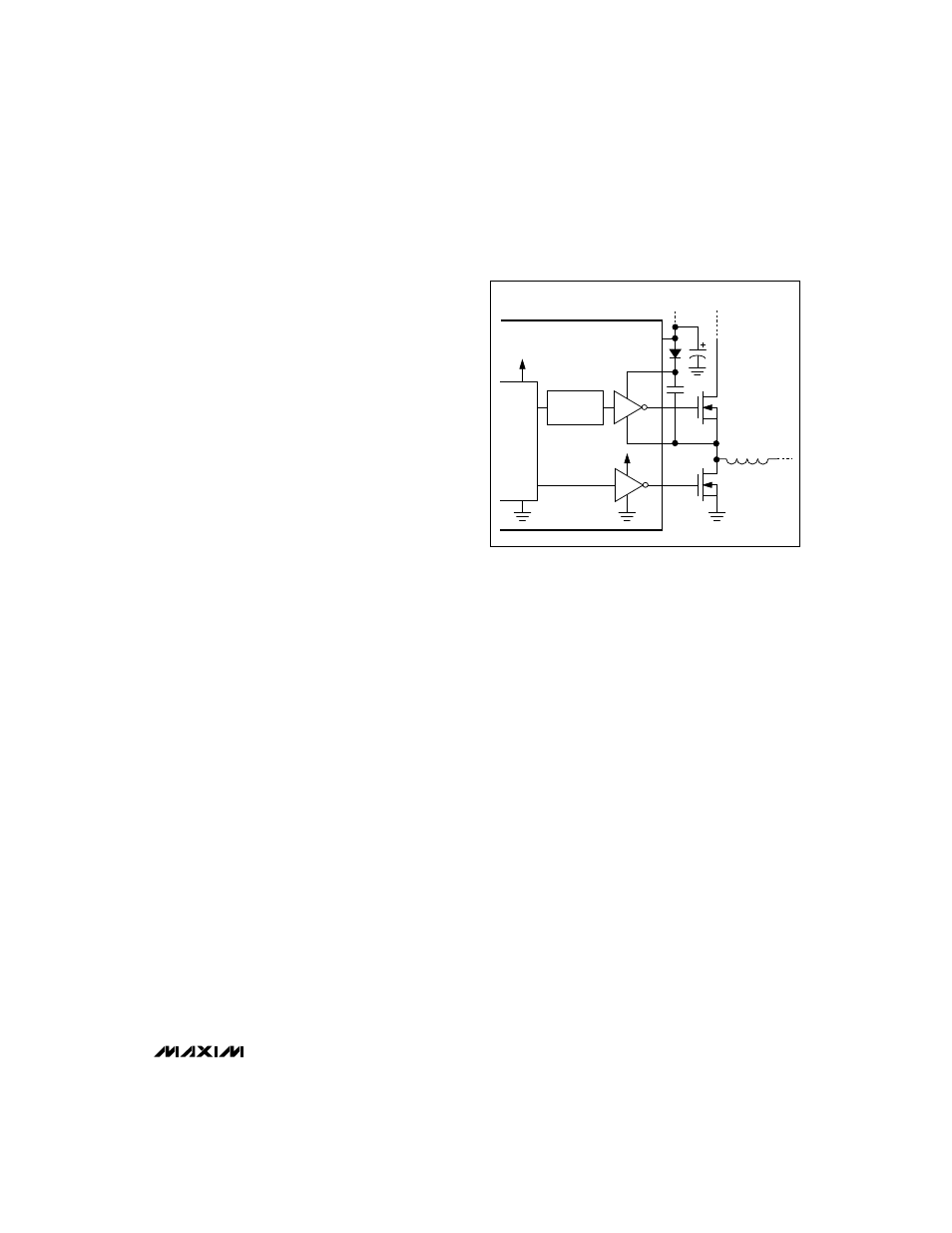

Boost Gate-Driver Supply

Gate-drive voltage for the high-side N-channel switch is

generated with a flying-capacitor boost circuit as shown

in Figure 4. The capacitor is alternately charged from

the VL supply via the diode and placed in parallel with

the high-side MOSFET’s gate-source terminals. On start-

up, the synchronous rectifier (low-side) MOSFET forces

LX_ to 0V and charges the BST_ capacitor to 5V. On the

second half-cycle, the PWM turns on the high-side

MOSFET by connecting the capacitor to the MOSFET

gate by closing an internal switch between BST_ and

DH_. This provides the necessary enhancement voltage

to turn on the high-side switch, an action that “boosts”

the 5V gate-drive signal above the battery voltage.

Ringing seen at the high-side MOSFET gates (DH3 and

DH5) in discontinuous-conduction mode (light loads) is

a natural operating condition caused by the residual

energy in the tank circuit formed by the inductor and

stray capacitance at the LX_ nodes. The gate driver

negative rail is referred to LX_, so any ringing there is

directly coupled to the gate-drive supply.

Modes of Operation

PWM Mode

Under heavy loads – over approximately 25% of full load

– the +3.3V and +5V supplies operate as continuous-cur-

rent PWM supplies (see

Typical Operating

Characteristics). The duty cycle (%ON) is approximately:

%ON = V

OUT

/V

IN

Current flows continuously in the inductor: First, it

ramps up when the power MOSFET conducts; then, it

ramps down during the flyback portion of each cycle

as energy is put into the inductor and then dis-

charged into the load. Note that the current flowing

into the inductor when it is being charged is also

flowing into the load, so the load is continuously

receiving current from the inductor. This minimizes

output ripple and maximizes inductor use, allowing

very small physical and electrical sizes. Output rip-

ple is primarily a function of the filter capacitor (C7 or

C6) effective series resistance (ESR) and is typically

under 50mV (see the

Design Procedure section).

Output ripple is worst at light load and maximum

input voltage.

Idle Mode

Under light loads (<25% of full load), efficiency is fur-

ther enhanced by turning the drive voltage on and off

for only a single clock period, skipping most of the

clock pulses entirely. Asynchronous switching, seen as

“ghosting” on an oscilloscope, is thus a normal operating

condition whenever the load current is less than

approximately 25% of full load.

At certain input voltage and load conditions, a transition

region exists where the controller can pass back and

forth from idle-mode to PWM mode. In this situation,

short bursts of pulses occur that make the current

waveform look erratic, but do not materially affect the

output ripple. Efficiency remains high.

Current Limiting

The voltage between CS3 (CS5) and FB3 (FB5) is contin-

uously monitored. An external, low-value shunt resistor is

connected between these pins, in series with the induc-

tor, allowing the inductor current to be continuously mea-

sured throughout the switching cycle. Whenever this

voltage exceeds 100mV, the drive voltage to the external

high-side MOSFET is cut off. This protects the MOSFET,

the load, and the battery in case of short circuits or tem-

porary load surges. The current-limiting resistor R1 (R2)

is typically 25m

Ω

(20m

Ω

) for 3A load current.

Oscillator Frequency; SYNC Input

The SYNC input controls the oscillator frequency.

Connecting SYNC to GND or to VL selects 200kHz opera-

tion; connecting to REF selects 300kHz operation. SYNC

can also be driven with an external 240kHz to 350kHz

CMOS/TTL source to synchronize the internal oscillator.

Normally, 300kHz is used to minimize the inductor and

filter capacitor sizes, but 200kHz may be necessary for

low input voltages (see

Low-Voltage (6-cell) Operation).

LEVEL

TRANSLATOR

PWM

VL

BST_

DH_

LX_

DL_

VL

BATTERY

INPUT

VL

Figure 4. Boost Supply for Gate Drivers