Assembly instructions (continued) – Wilwood Forged Dynalite Rear Drag Brake Kit User Manual

Page 4

Assembly Instructions (numbers in parenthesis refer to

the part list/diagram on the preceding page): CAUTION: All

mounting bolts must fully engage insert nuts. Be sure to

check that all bolts are either flush or protruding through

flanged side of insert nut after shimming.

•With the slot pointing upward and the mounting ears

pointing towards the rear of the vehicle, install the caliper

mounting bracket (1) to the housing flange using the stock

Original Equipment Manufacturer (OEM) bolts and nuts.

Stock OEM hex nuts that retain the bracket (1) should be

on the wheel side of the bracket. Apply red Loctite® 271

to the stock OEM bolt threads and torque to OEM

specifications. NOTE: Some brackets act as the bearing

retainers, while others help locate the bearing in the axle

housing flange. If the stock bearing plates are still on the

axle, the caliper mounting brackets (1) should be located

between the axle housing flange and the bearing retainer

plate. Make sure the heads of the caliper mounting

bracket insert nuts are FACING OUTWARD TOWARDS

THE WHEEL.

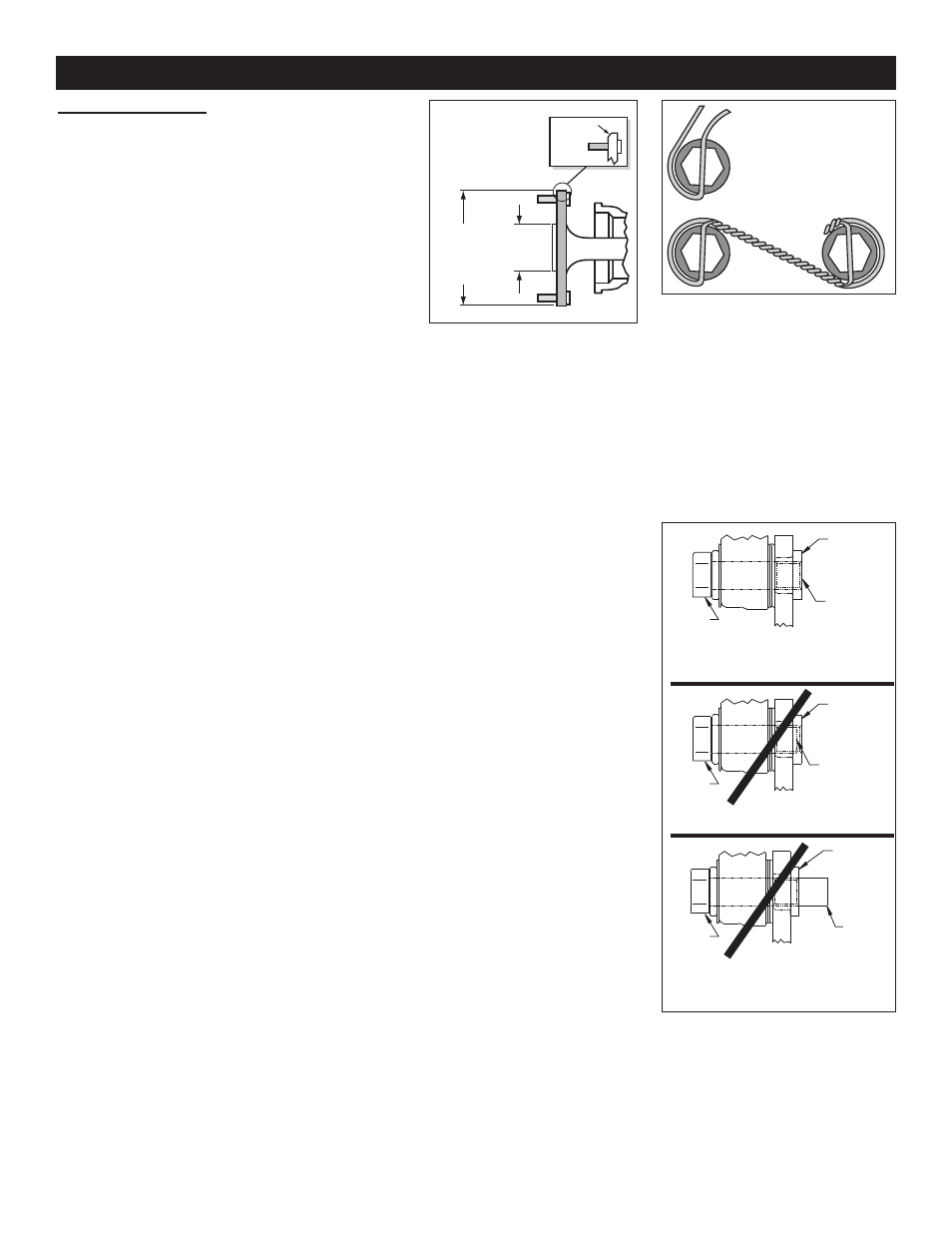

•The rotor (3) has two sides. A flat side and an inset side. Bolt hat (2) to flat side of rotor

(3) using bolts (5). Using an alternating sequence, apply red Loctite® 271 to the threads and

torque bolts to 25 ft-lb. For an added measure of security, the bolts may be safety wired using

standard 0.032 inch diameter stainless steel safety wire as shown in Figure 4. Refer to

Wilwood’s data sheet DS-386 (available at

www.wilwood.com/Pdf/DataSheets/ds386.pdf

) for

complete safety wire installation instructions.

•Align the correct hole pattern in the hat (2) with the stud pattern on the axle flange.

NOTE: Some OEM and after market axles come with stud sizes larger than 0.50” diameter.

Verify stud size and have a qualified machine shop drill the hats to the correct size. Slide the

hat/rotor assembly (2 and 3) over the wheel studs and against the axle flange face.

•NOTE: Please reference the caution statement at the beginning of the assembly instructions.

Mount the caliper (6) over the rotor (3) and onto the caliper mounting bracket (1) using washers

(7) and mounting bolts (8). View the rotor through the top opening of the caliper. The rotor should

be aligned in the center of the caliper. If not, adjust the caliper by using 0.032 inch shims (9)

by placing them between the caliper mounting bracket (1) and the caliper (6). Add as many

shim washers (9) as necessary to achieve the correct alignment. NOTE: The end of the bolt

must be flush with or slightly protuding from the head of the clinch nut. See Figure 5. Place

spare shims (9) between washer and caliper mounting ear to achieve the proper mounting

fastener configuration. Always use the same amount of shims on both the top and bottom

caliper mounting bolts (8). Apply red Loctite® 271 to the mounting bolt threads (8), torque to

40 ft-lb. Caliper mount bolts may be safety wired for additional security.

•Position the Wilwood disc brake pads (10) into the caliper (6) and fasten with cotter pin (4).

Steel backing plate side of brake pad should face the caliper pistons.

•NOTE: OEM rubber brake hoses generally cannot be adapted to Wilwood calipers. The caliper

inlet fitting is a 1/8-27 NPT. The preferred method is to use steel adapter fittings at the caliper,

either straight, 45 or 90 degree and enough steel braided line to allow for full suspension travel

and turning radius, lock to lock. Carefully route lines to prevent contact with moving

suspension, brake or wheel components. Wilwood hose kits are designed for use in many

different vehicle applications and it is the installer's responsibility to properly route and ensure

adequate clearance and retention for brake hose components.

BEGIN BY SLIDING THE 0.032"

DIAMETER WIRE THROUGH TWO OF

THE HOLES (LEFT) THAT ARE 180°

APART. TWIST THE WIRE AS

SHOWN (BELOW) USING SAFETY

WIRE PLIERS. NOW SLIDE ONE

WIRE THROUGH TWO OF THE

HOLES (180° APART) AND WRAP THE

OTHER WIRE AROUND THE BOLT.

TWIST THE WIRES TOGETHER TO

FORM A PIGTAIL. SEE DS-386 FOR

COMPLETE DETAILS.

Figure 4. Safety Wire Diagram

Assembly Instructions (Continued)

Page 4

END OF BOLT

HEAD

OF BOLT

HEAD

OF BOLT

HEAD

OF BOLT

CORRECT

END OF BOLT IS FLUSH WITH, OR SLIGHTLY

PROTRUDING FROM END OF CLINCH NUT

WRONG

END OF BOLT IS BELOW END OF CLINCH NUT

WRONG

END OF BOLT IS PROTRUDING TOO FAR

FROM END OF CLINCH NUT AND MAY

INTERFERE WITH MOVING PARTS

END OF

CLINCH NUT

END OF

CLINCH NUT

END OF

CLINCH

NUT

END OF BOLT

END OF

BOLT

Figure 5.

Clinch Nut Engagement Diagram

Figure 3. Axle Flange

Maximum Dimension

MAXIMUM

DIA 6.11"

TO FIT

WILWOOD

HAT

3.06”

REGISTER

.050 X 45°

CHAMFER