Wilwood Forged Dynalite User Manual

Forged billet dynalite caliper, Caliper highlights

4700 Calle Bolero • Camarillo, CA 93012 Sales: 805 / 388-1188 • Fax: 805 / 388-4938 • www.wilwood.com

104 REV DATE: 05-25-04

FORGED BILLET DYNALITE CALIPER

Caliper Highlights:

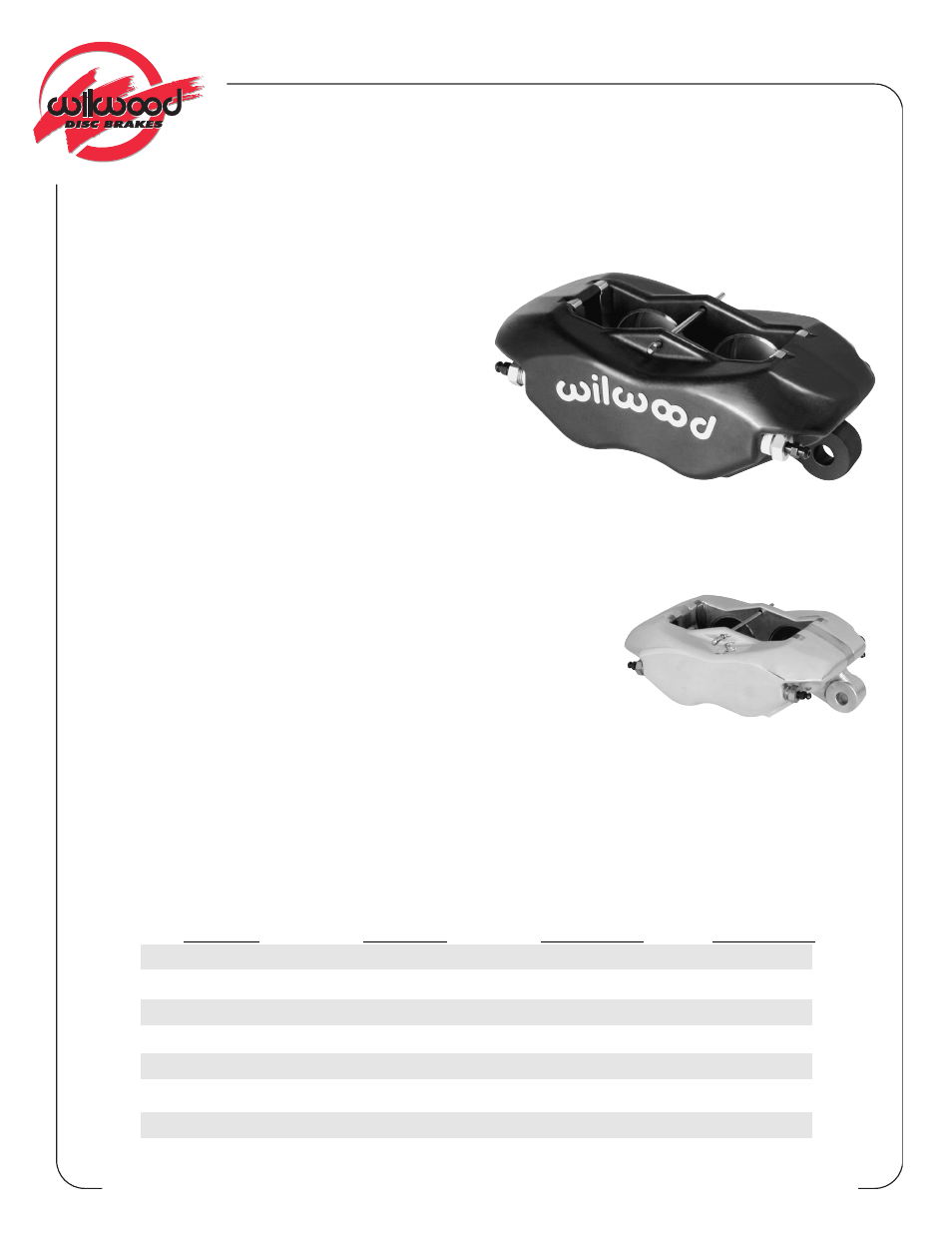

The Dynalite caliper series has widespread application over many

forms of motorsports. The Forged Billet Dynalite is the latest

innovation from Wilwood providing substantial improvements in

strength and performance over all comparable caliper models.

Forged Dynalites are the strongest calipers in the class. The

process of stress-flow forging re-aligns the metal's grain structure

within the contour of the caliper body. This process eliminates the

breaks and interruptions to the internal grain structure that occur when

machining a straight block billet. The FEA generated radial transition

design eliminates steps and shoulders in the area between the piston housing

body and the caliper bridges. Incorporating a radius in this transition area

substantially increases resistance to deflection and caliper separation under load.

Structural deflection and volume displacement tests have proven the Forged Dynalite to outperform all

existing styles of this popular caliper size. Without even considering the overall greater strength and reliability of the forging, the reduced

deflection tendencies and the resulting decrease in fluid volume displacement translate to increased clamping efficiency with less pedal

travel. The bottom line is a taller pedal and better stopping power.

The superior strength of this innovative design is combined with proven performance

features from Wilwood's earlier designs. Each caliper is equipped with Wilwood's SRS

stainless steel bridge plates. The SRS plates eliminate the bridge wear caused by pad

gouging and extend the service life of the caliper body. The spring-loading action of the

SRS plates also eliminates pad rattle and dampens the vibration harmonics that

contribute to squeal under braking. Other standard Wilwood features include high

temperature seals and stainless steel pistons to eliminate corrosion and retard heat

transfer from the pads. Internal fluid passages eliminate the need for external tubes. Four

corner bleed screws assure simple and effective air evacuation from the system and allow one

caliper to be mounted in any front, rear, right or left position. Standard race calipers feature Wilwood's signature bright

black anodized finish to resist corrosion and maintain their high tech style. Polished calipers (shown above) are also available for custom

show car applications.

Forged Dynalite calipers are a direct replacement for all Wilwood Dynalite and similar competitive brand calipers with 5.25" centered

mounting tabs. The Forged Dynalite uses the same 7112 type brake pad used in all earlier versions of this caliper. The full range of

PolyMatrix pad compounds is available to match brake response and heat range to any application.

ORDERING INFORMATION:

BLACK

POLISHED

BORE SIZE

DISC WIDTH

PART NUMBER

PART NUMBER

1.75”

44,5 mm

1.25”

31,8 mm

120-6814

—

1.75”

44,5 mm

1.00”

25,4 mm

120-6815

—

1.75”

44,5 mm

.81”

20,6 mm

120-6816

—

1.75”

44,5 mm

.50”

12,7 mm

120-6817

—

1.75”

44,5 mm

.38”

9,7 mm

120-6818

—

1.62”

41,1 mm

1.25”

31,8 mm

120-6809

120-6794-P

1.62”

41,1 mm

1.00”

25,4 mm

120-6810

120-6795-P

1.62”

41,1 mm

.81”

20,6 mm

120-6811

120-6796-P

1.62”

41,1 mm

.50”

12,7 mm

120-6812

120-6797-P

1.62”

41,1 mm

.38”

9,7 mm

120-6813

120-6798-P

1.38”

35,1 mm

1.25”

31,8 mm

120-6804

120-6789-P

1.38”

35,1 mm

1.00”

25,4 mm

120-6805

120-6790-P

1.38”

35,1 mm

.81”

20,6 mm

120-6806

120-6791-P

1.38”

35,1 mm

.50”

12,7 mm

120-6807

120-6792-P

1.38”

35,1 mm

.38”

9,7 mm

120-6808

120-6793-P