Assembly instructions – Wilwood Dynapro 6 Big Brake Front Brake Kit (Hat) User Manual

Page 4

Assembly Instructions (numbers in parenthesis refer to the parts list and Figure 1 on the preceding pages):

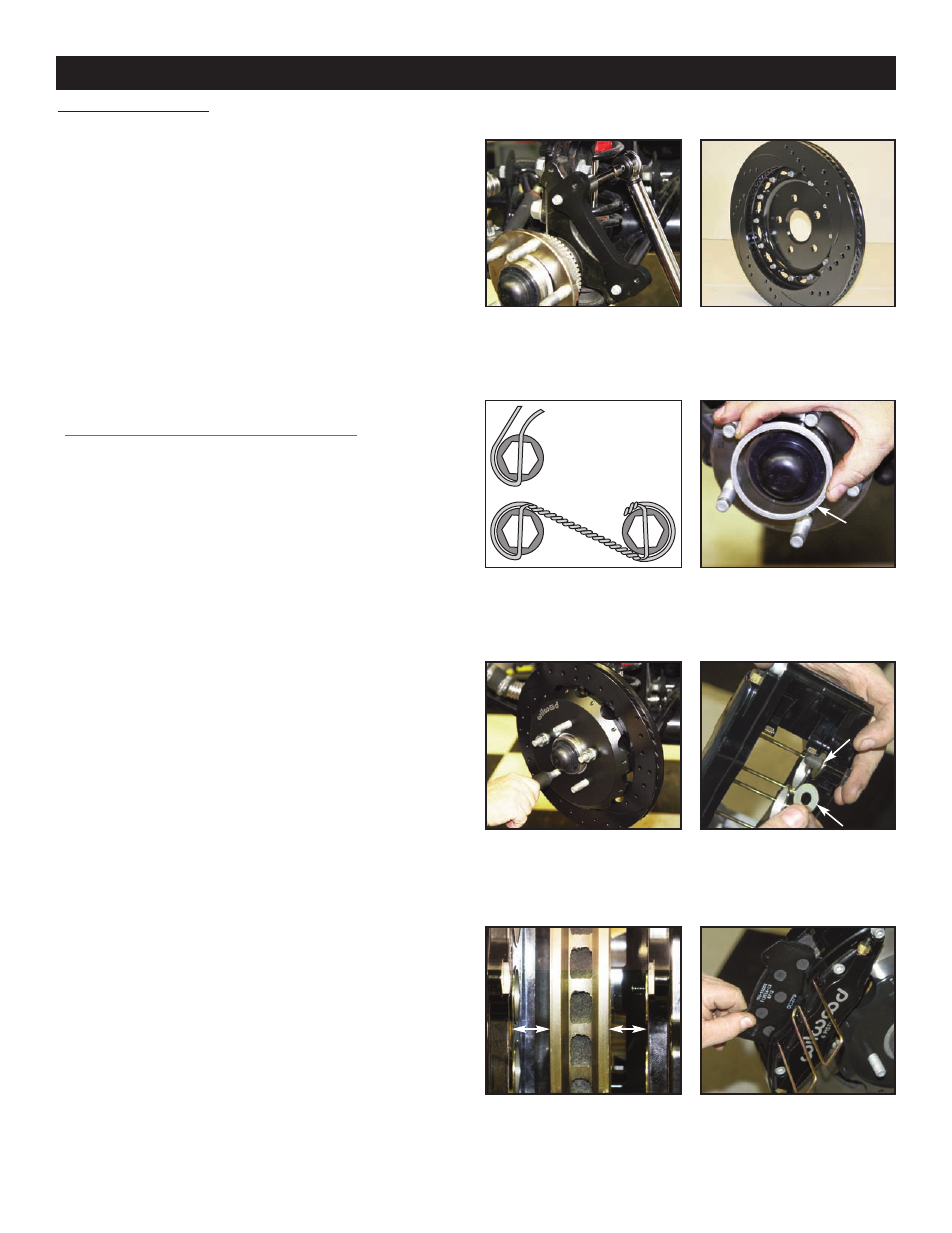

• Orient the caliper mount bracket (1) as shown in Figure 1 and

Photo 1, and install using bolts (2) and washers (3). Temporarily

tighten the mounting bolts. NOTE: The bracket must fit squarely

against the mount bosses on the upright.

Inspect for

interference from casting irregularities, machining ridges, burrs,

etc. Remove bolts one at a time, apply red Loctite

®

271 to the

threads and torque to 60 ft-lb.

• Orient the rotor (5) and the hat (6) as shown in Figure 1 and

Photo 2. Attach rotor to hat using bolts (8) and washers (7).

Using an alternating sequence, apply red Loctite® 271 to the

threads and torque bolts to 155 in-lb. For an added measure of

security, the bolts may be safety wired using standard 0.032 inch

diameter stainless steel safety wire as shown in Figure 3.

Please refer to Wilwood’s data sheet DS-386 (available at

www.wilwood.com/Pdf/DataSheets/ds386.pdf

) for complete

safety wire installation instructions.

•Slide the rotor registration adapter (4) onto the axle register on

the axle hub with the smaller O.D. facing toward the rotor/hat

(5/6), Photo 3. Slide the hat/rotor assembly onto the axle hub,

Photo 4. NOTE: The hat must fit flush against the axle hub

flange or excessive rotor run out may result. Install three lug nuts

(finger tight) to keep the hat/rotor assembly in place while

continuing with the installation.

•NOTE: This kit contains distinct right and left hand calipers that

must be mounted in a specific direction, as described below.

Mount the caliper (9) onto the caliper mounting bracket (1) using

bolts (11) and washers (10), as shown in Figure 1. Initially

place one each .016” thick shim (12) and .035” thick shim (13) on

each bolt between the caliper and the bracket, Figure 1 and

Photo 5. Ensure that the caliper is mounted so the largest pistons

are at the rotor exit end of the caliper, in relation to the direction of

rotor rotation. Temporarily tighten the mounting bolts and view

the rotor (5) through the top opening of the caliper. The rotor

should be centered in the caliper, Photo 6. If not, adjust by

adding or subtracting shims (12 and/or 13) between the bracket

and the caliper. Always use the same amount of shims on each

of the two mounting bolts. Once the caliper alignment is correct,

remove the bolts one at a time, apply red Loctite® 271 to bolt

threads, and torque to 35 ft-lb.

•Install the disc brake pads (14) into the caliper, with the friction

material facing the rotor (5), and secure in place using the pad

clip retainer (15), Photo 7.

•Temporarily install wheel and torque lug nuts to manufacturer’s

specification. Ensure that the wheel rotates freely without any

interference.

Assembly Instructions

Photo 1

Photo 4

Photo 3

Photo 2

Page 4

Small

O.D.

toward

rotor/hat

Photo 5

Photo 7

Photo 6

BEGIN BY SLIDING THE 0.032"

DIAMETER WIRE THROUGH TWO OF

THE HOLES (LEFT) THAT ARE 180°

APART. TWIST THE WIRE AS

SHOWN (BELOW) USING SAFETY

WIRE PLIERS. NOW SLIDE ONE

WIRE THROUGH TWO OF THE

HOLES (180° APART) AND WRAP THE

OTHER WIRE AROUND THE BOLT.

TWIST THE WIRES TOGETHER TO

FORM A PIGTAIL. SEE DS-386 FOR

COMPLETE DETAILS.

Figure 3. Safety Wire Diagram