Assembly instructions (continued), Additional information and recommendations – Wilwood Promatrix Rear Replacement Rotor Kit User Manual

Page 4

Assembly Instructions (Continued)

Page 4

• Orient the rotor (5) and the hat (6) as shown in Figure 1. Attach rotor to hat using bolts (7)

and washers (8). Using an alternating sequence, apply red Loctite

®

271 to the threads, and

torque to 155 in-lbs. For an added measure of security, the bolts may be safety wired using

standard 0.032 inch diameter stainless steel safety wire as shown in Figure 3. Please refer

to Wilwood’s data sheet DS-386 (available at

www.wilwood.com/Pdf/DataSheets/ds386.pdf

)

for complete safety wire installation instructions.

•Slide the rotor registration adapter (9) onto the axle register on the axle flange with the

smaller O.D. facing toward the hat/rotor (5/6). Slide the hat/rotor assembly onto the axle

hub. NOTE: The hat must fit flush against the axle hub flange or excessive rotor run out

may result. Install three lug nuts (finger tight) to keep the rotor in place while continuing with

the installation.

•Mount the caliper (Shelby supplied) onto the caliper mounting bracket (1) using bolts (10) as

shown in Figure 1. Torque caliper mounting bolts to 70 ft-lb.

•NOTE: For best performance and service life, Wilwood recommends using new brake pads with new replacement rotors.

• Remove the lug nuts that were holding the rotor in place. Install the wheel and torque the lug nuts to the manufacturer’s specification.

Ensure that the wheel rotates freely without any interference.

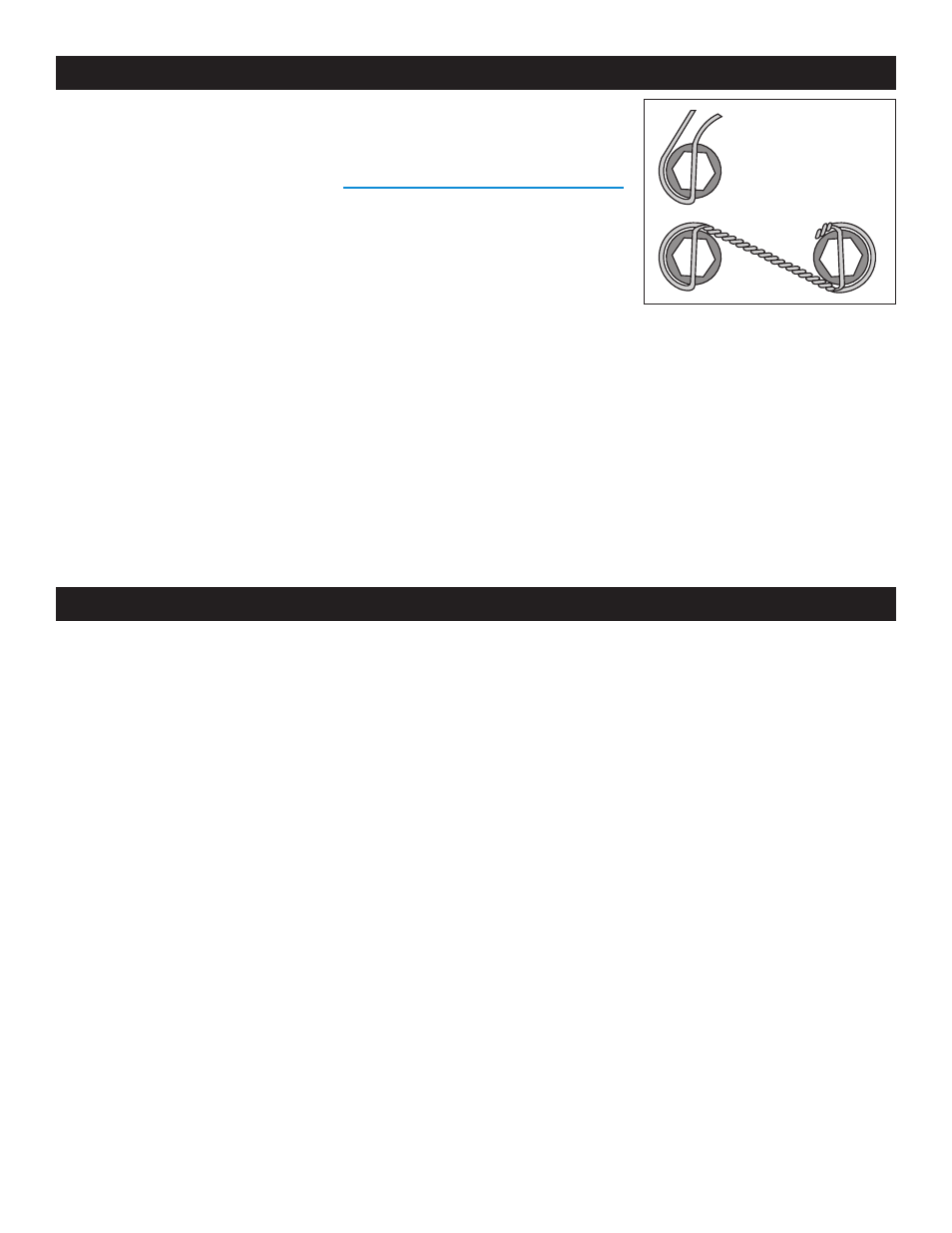

BEGIN BY SLIDING THE 0.032"

DIAMETER WIRE THROUGH TWO OF

THE HOLES (LEFT) THAT ARE 180°

APART. TWIST THE WIRE AS

SHOWN (BELOW) USING SAFETY

WIRE PLIERS. NOW SLIDE ONE

WIRE THROUGH TWO OF THE

HOLES (180° APART) AND WRAP THE

OTHER WIRE AROUND THE BOLT.

TWIST THE WIRES TOGETHER TO

FORM A PIGTAIL. SEE DS-386 FOR

COMPLETE DETAILS.

Figure 3. Safety Wire Diagram

Additional Information and Recommendations