Wilwood MasterCylinder No: 260-11322 User Manual

Page 2

• Make sure pedal is firm: Hold firm pressure on pedal for several minutes, it should remain in position without

sinking. If pedal sinks toward floor, check system for fluid leaks. DO NOT drive vehicle if pedal does not stay firm

or can be pushed to the floor with normal pressure.

• At very low speed (2-5 mph) apply brakes hard several times while turning steering from full left to full right, repeat

several times. Remove the wheels and check that components are not touching, rubbing, or leaking.

• Carefully examine all brake components, brake lines, and fittings for leaks and interference.

• Make sure there is no interference with wheels or suspension components.

• Drive vehicle at low speed (15-20 mph) making moderate and hard stops. Brakes should feel normal and

positive. Again check for leaks and interference.

• Always test vehicle in a safe place where there is no danger to (or from) other people or vehicles.

• Always wear seat belts and make use of all safety equipment.

WARNING • DO NOT DRIVE ON UNTESTED BRAKES

BRAKES MUST BE TESTED AFTER INSTALLATION OR MAINTENANCE

MINIMUM TEST PROCEDURE

Fluid: The Wilwood proportioning valve is fully

compatible with all types of brake fluid including DOT

3, 4, 5, and 5.1 fluids. DOT 3, 4 and 5.1 fluids are

fully miscible, but DOT 5 silicone fluid should never

be mixed with any other fluids. Always follow the

vehicle manufacturers fluid recommendations for

any vehicle. A complete flush and fill with fresh fluid

is recommended for all installations. For best

performance, use Wilwood Hi-Temp 570, EXP 600

Plus, or Wilwood FIVE DOT 5 high performance

fluids.

Bleeding: To properly bleed the brake system, begin

with the caliper farthest from the master cylinder. For

fixed mount calipers with two bleed screws on top,

bleed the outboard bleed screw first, then bleed the

inboard screw. Repeat this procedure until all

calipers have been bled, ending with the caliper

closest to the master cylinder. Once the system has

been bled, the pedal should maintain a consistent,

firm feel. If the pedal returns to a spongy feel after it

has rested from the bleeding process, this is an

indication that air still exists in the system. If this

occurs, repeat the bleeding process until all air has

been purged and the pedal retains a firm feel. NOTE:

When installing a new master cylinder, it is important

to follow proper bench bleeding procedures. Follow

the installation instructions provided with the new

master cylinder. If a firm pedal can not be achieved

after bleeding the system, the master cylinder may

not be properly sized for the brake system.

Proportioning Valve Adjustment: The proportioning valve is non-adjustable by the user and functions automatically. NOTE: For safety and

performance, the rear brakes should never lock before the front brakes. Otherwise, an out of control situation could occur.

Help: If after following the instructions, you still have difficulty with installing, or bleeding the system please consult your chassis builder, the

retailer where the valve was purchased, a qualified brake technician, or Wilwood Customer Service at (805) 388-1188.

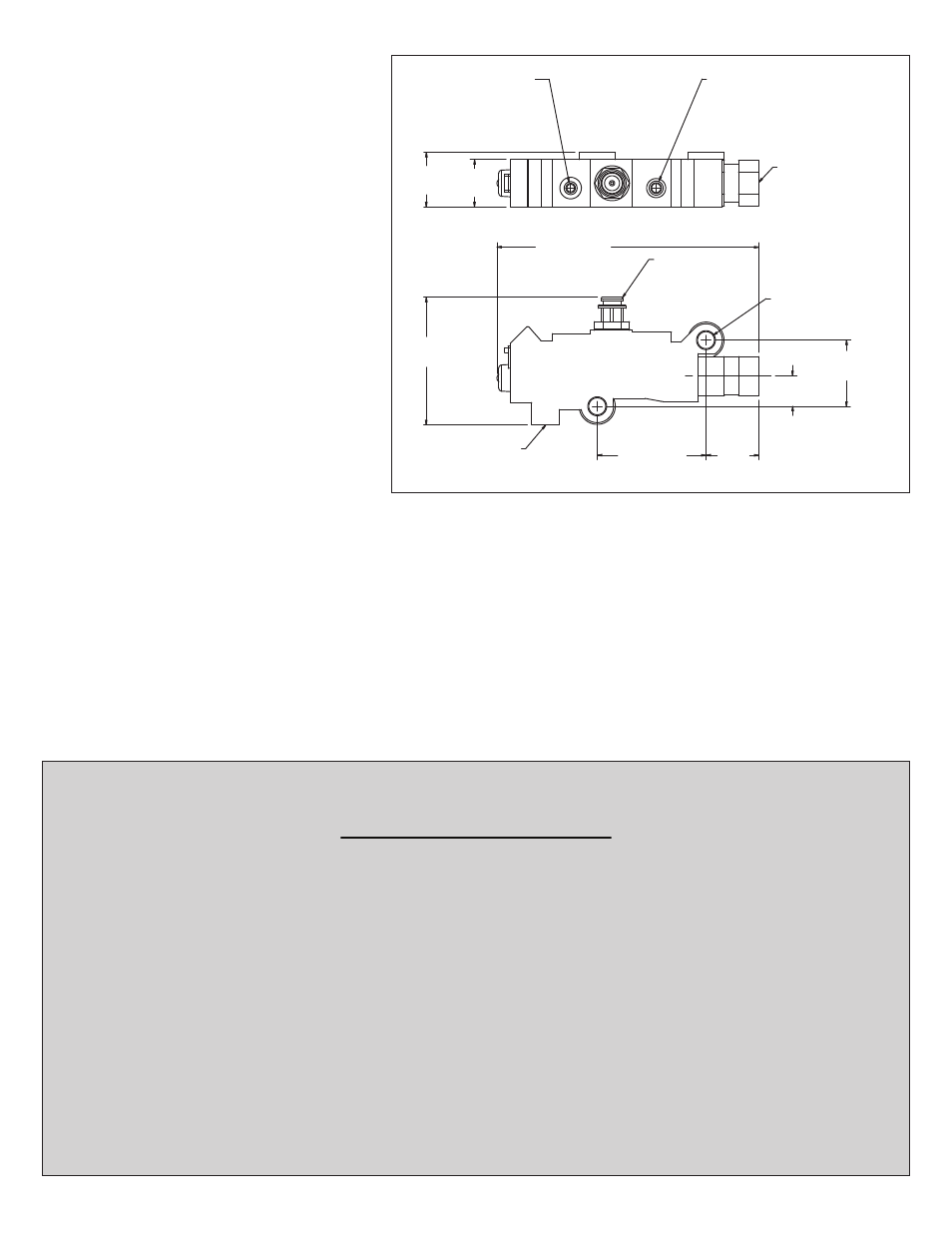

5.41 (137,5)

2.25 (57,1)

CIRCUIT

FAILURE

SWITCH

CONNECTION

.97

(24,7)

1.12

(28,5)

2.63

(66,8)

1.37

(34,7)

.62

(15,8)

1.09

(27,8)

9/16-18 THREAD

INVERTED FLARE

(REAR BRAKES

OUTLET)

.35 (8,9) MOUNTING

HOLE 2 PLACES

7/16-24 THREAD

INVERTED FLARE

(REAR BRAKES

INLET FROM

MASTER CYLINDER

3/8-24 THREAD

INVERTED FLARE

(FRONT BRAKES OUTLET)

1/2-20 THREAD

INVERTED FLARE

(FRONT BRAKES

INLET FROM

MASTER CYLINDER

Figure 1. Combination Proportioning Valve, Mounting Dimensions