Wilwood MasterCylinder No: 260-3501 User Manual

Page 2

These part numbers are provided for your convenience. Ask your Wilwood representative for assistance when ordering.

Part No.

Description

Part No.

Description

190-4743

SL III, SL-GT, LC-GT Self Bleed Line (1.25” rotor)

190-5040

Billet Superlite (1.25” rotor)

190-3615

GN III (1.38” rotor)

190-3524

GT 6000 (1.38” rotor)-see note below

190-4357

GT III (1.38” rotor)

190-5222

Prolite (1.38” rotor)

190-5144

Integra / Integra 6 / Integra 6R (1.25/1.31/1.38” rotor)

190-5604

Prolite 6 / Prolite 6R (1.38” rotor)

260-3501

Flow Valve

220-0628

Tube Adapter (4 Pack)

290-0632

Wilwood Racing Brake Fluid (Hi-Temp° 570)

290-6209

Wilwood EXP 600 Plus Brake Fluid

Note: GT 6000 Brass Tube Seat (required) P/N 220-2703

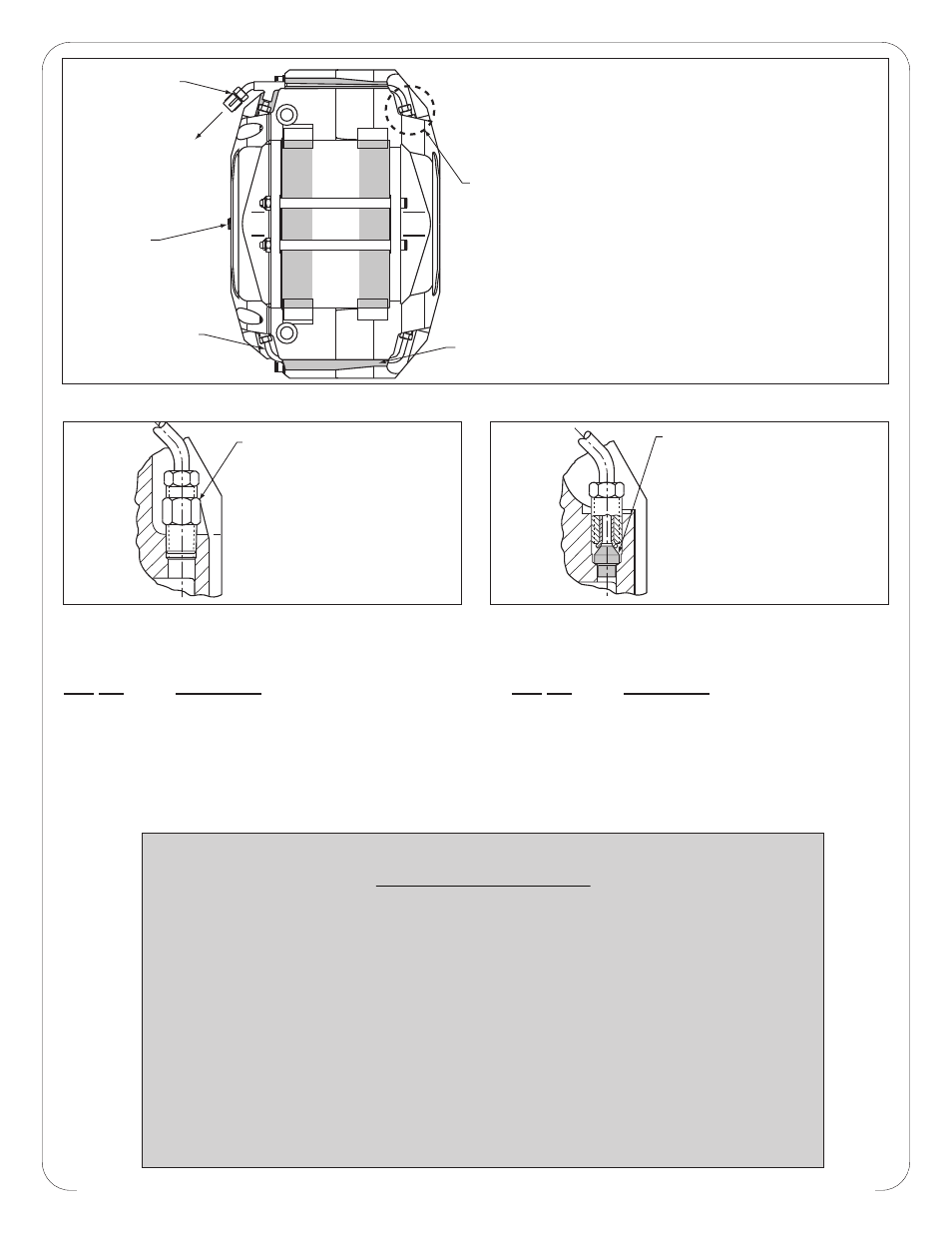

RETURN

(-3 FITTING)

INLET

EXISTING

CROSSOVER

TUBE

SEE DETAIL "A" OR "B" AS APPROPRIATE

SELF BLEEDER

TUBE ASSEMBLY

PROVIDE VIBRATION DAMPENING BY FILLING SHADED AREA

BETWEEN THE HORIZONTAL PORTION OF TUBE AND CALIPER

WITH RED RTV #736. (RTV MUST FILL ENTIRE LENGTH OF TUBE).

Typical Caliper Configuration

REMOVE BOTH ORIGINAL BLEED

SCREWS AND INSTALL BRASS

INVERTED FLARE TUBE SEAT AT

EACH LOCATION.

USING THE LONG TUBE NUT

SUPPLIED, TIGHTEN THE TUBE

NUT, FINGER TIGHT, TO

PROPERLY ALIGN SEAT INSERT.

REMOVE THE TUBE NUT AND

INSTALL NEW CROSSOVER

RETURN TUBE ASSEMBLY.

CHECK FOR LEAKS BEFORE

OPERATING.

Detail “B” (GT 6000 Only)

REMOVE BOTH BLEED SCREW

ASSEMBLIES AND INSTALL

TUBE ADAPTERS.

INSTALL NEW CROSSOVER

RETURN TUBE ASSEMBLY.

CHECK FOR LEAKS BEFORE

OPERATING.

Detail “A” (Standard Fitting)

Wilwood Disc Brakes • 4700 Calle Bolero, Camarillo, CA 93012

Phone 805 / 388-1188 • Fax 805 / 388-4938

www.wilwood.com

DS-213H REV DATE: 06-29-09

• Make sure pedal is firm: Hold firm pressure on pedal for several minutes, it should remain in position without

sinking. If pedal sinks toward floor, check system for fluid leaks. DO NOT drive vehicle if pedal does not stay firm

or can be pushed to the floor with normal pressure.

• At very low speed (2-5 mph) apply brakes hard several times while turning steering from full left to full right, repeat

several times. Remove the wheels and check that components are not touching, rubbing, or leaking.

• Carefully examine all brake components, brake lines, and fittings for leaks and interference.

• Make sure there is no interference with wheels or suspension components.

• Drive vehicle at low speed (15-20 mph) making moderate and hard stops. Brakes should feel normal and

positive. Again check for leaks and interference.

• Always test vehicle in a safe place where there is no danger to (or from) other people or vehicles.

• Always wear seat belts and make use of all safety equipment.

WARNING • DO NOT DRIVE ON UNTESTED BRAKES

BRAKES MUST BE TESTED AFTER INSTALLATION OR MAINTENANCE

MINIMUM TEST PROCEDURE