Cut out discharge hole in trough bottom, Figure 1 – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-765 User Manual

Page 4

4

PNEG-765 Gate Manual

A

C

B

D

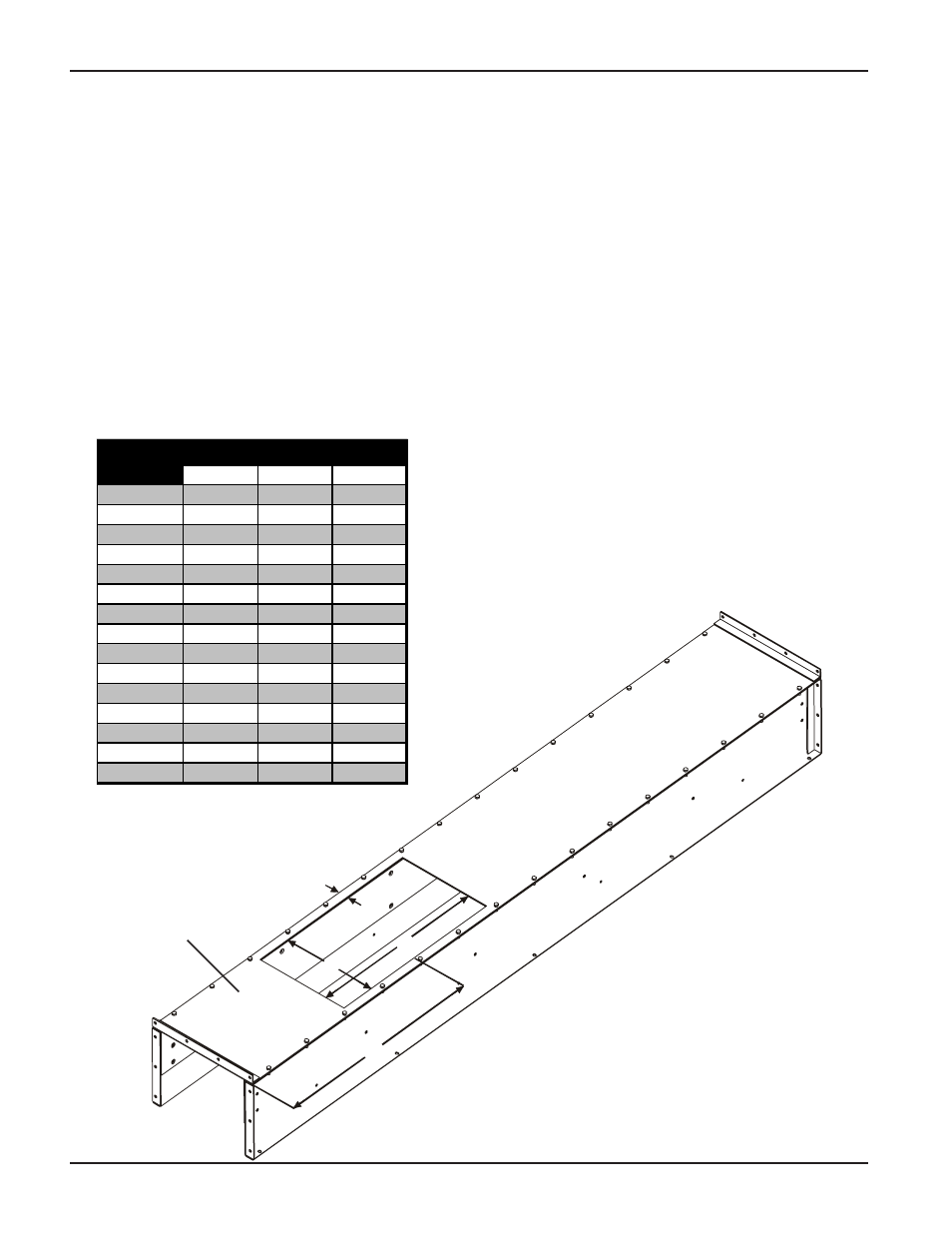

Figure 1

1. To find where to cut hole in trough bottom, start by locating the center of the purposed discharge.

Dimension “A”. (Refer to Figure 1.)

2. When locating discharges try to position opening so that gate flange hole pattern and conveyor

hole pattern lineup. The gate has slotted holes to allow for adjustment to nearest 1".

3. If this cannot be achieved then holes must be drilled on site.

4. Find dimensions “B” and “C” corresponding to your conveyor size. Use “D” dimensions as a

reference. (See Figure 1 and chart below.)

5. Mark the cut out from outside the conveyor on the trough bottom.

6. Cut opening into the bottom being careful not to damage other components of the Conveyor.

Remove all burrs and rough edges from the opening.

Cut Out Discharge Hole in Trough Bottom

Conveyor

Bottom

Conv. Size

B

C

D

0912

9.00

30.125

1.50

1212

12.00

30.125

1.50

1612

16.00

30.125

1.50

1214

12.00

30.125

1.50

1614

16.00

30.125

1.50

2114

21.00

30.125

1.50

1420

14.00

36.125

2.00

1620

16.00

36.125

2.00

2020

20.00

36.125

2.00

2620

26.00

36.125

2.00

3220

32.00

36.125

2.00

2626

26.00

36.125

2.00

3226

32.00

36.125

2.00

3232

32.00

36.125

2.00

3632

36.00

36.125

2.00

Trough Hole Dimensions