Banks Power Chevy_GMC Trucks: Diesel ’93 - 96 6.5L Power Systems- Stinger System '93-early '94 (non-cat) & '94-up ( w_ cat) Pickups & Suburbans w_ factory turbo option User Manual

Page 9

9

extended cab and crew cab models: The extension

pipe will install between the turbine outlet pipe

and the intermediate pipe. Temporarily place the

intermediate pipe, muffler and tailpipe in place

using the hangers and hanger clamps. position the

components such that the turbine outlet pipe and

the intermediate pipe are in alignment with each

other and the rubber hangers are swung slightly

forward (see Figure 6). Measure the distance from

the outlet end of the turbine outlet pipe to the

inlet of the intermediate pipe. add approximately

5” to allow for the two slip joints, and cut the

extension pipe to the appropriate length (crew cab

applications may not need to be cut).

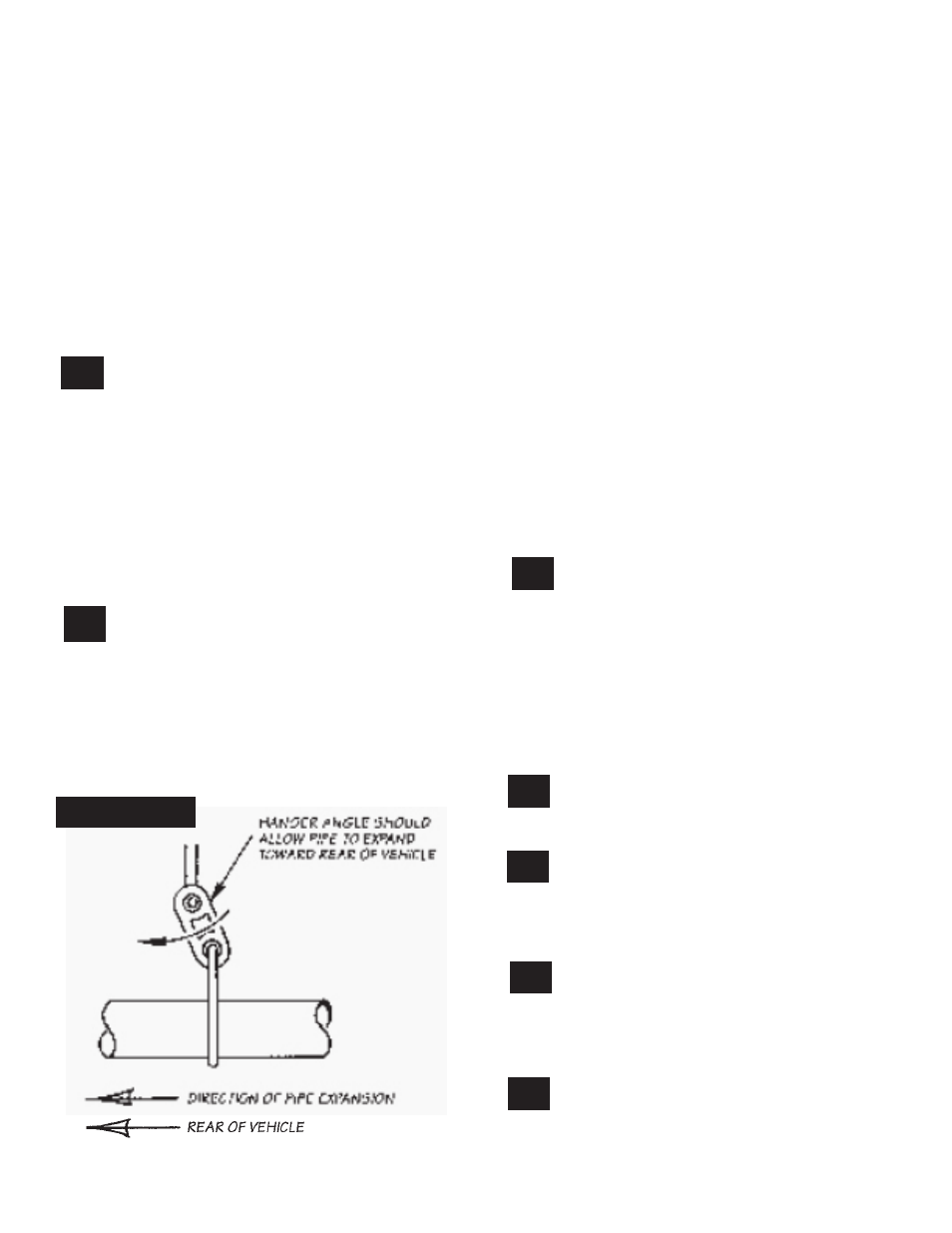

16.

adjust the position of the complete exhaust

system to provide maximum clearance to the

frame and other components. check the alignment

of the muffler and the tailpipe. The muffler should

be straight and level, and the rubber hangers should

be swung forward toward the front of the vehicle

3

⁄

4

”

to 1” to allow for expansion of the pipes. See Figure

6. When alignment and clearances are proper,

tighten all clamps including the factory v-band

clamp on the turbine outlet pipe.

proceed to step 19.

17.

loosely clamp the new turbine outlet pipe to

the turbocharger. reinstall the catalytic

converter assembly onto the turbine outlet pipe with

the provided gasket and hardware. suburban

models require that the inlet to the catalytic

converter be cut at the location indicated in figure

5c. slide the proper banks intermediate pipe onto

figure 6

the converter assembly with the large notch aligned

with the locating pin on the converter assembly and

clamp lightly to hold in position. See figure

5B/5C

.

Standard cab/Suburban models: install the

muffler and then the tailpipe.

extended cab and crew cab: tighten the 3” clamp

at the joint of the intermediate pipe and catalytic

converter assembly. place the tailpipe into position

and install 3

1

⁄

2

” hanger clamp into the rubber hanger.

place the muffler outlet over the end of the tailpipe

and hold it in position, level and straight, with a jack

or other suitable support. check that the hangers

are angled properly, and that the tailpipe outlet is

level with the vehicle. Measure the distance from

the dimples in the muffler inlet where the extension

pipe will stop to the end of the intermediate pipe.

add 2

3

⁄

4

” to the measurement to compensate for the

slip joint on the extension pipe. cut the extension

to this length (crew cab applications may not

need trimming). install the trimmed pipe onto the

intermediate pipe and into the muffler. install the 3”

hanger clamp into the rubber hanger on the frame

and lightly clamp it to the extension pipe.

18.

adjust the turbine outlet pipe and exhaust

system to provide maximum clearance to the

frame and other components. check the alignment

of the muffler and tailpipe to hangers and vehicle.

The muffler should be straight and level, and the

rubber hangers should be swung or angled towards

the front of the vehicle

3

⁄

4

” to 1” to allow for

expansion of the pipes. When alignment and

clearances look good, tighten all clamps including

the factory v-band on the turbine outlet pipe.

19.

reinstall the air cleaner assembly on right

inner fender panel. reinstall the vent hose

and tighten hose clamps.

20.

install new air filter supplied. see air filter

cleaning and maintenance instructions

elsewhere in this booklet.

GAUGE INSTALLATION (PART 2 OF 2)

21.

remove the pipe plug and install the

pyrometer gauge probe in the bung on the

turbo exhaust outlet pipe. We suggest using an

anti-sieze compound on the probe threads to

make removal easier for any future service.

22.

install instrument gauge panel in a location

providing easy viewing for the driver. nOTe:

Molded instrument consoles for top-of-dash

mounting and additional gauges are available

through gale banks engineering.

p.n. 96309 v.3.0