Banks Power Chevy_GMC Trucks: Diesel ’93 - 96 6.5L Power Systems- Stinger System '93-early '94 (non-cat) & '94-up ( w_ cat) Pickups & Suburbans w_ factory turbo option User Manual

Page 10

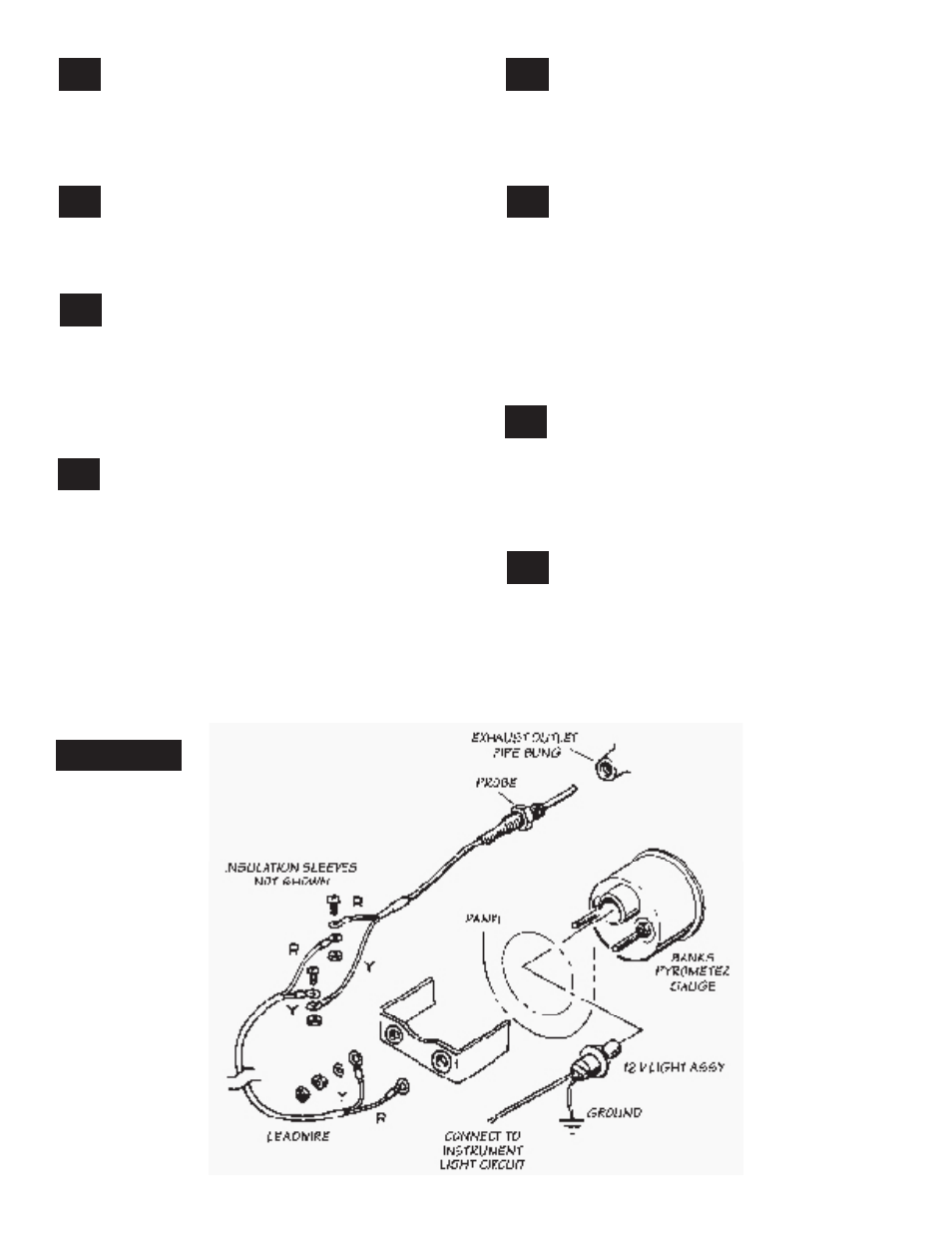

slide the protective sleeves over the longer

of each of the wire ends on the probe and

the leadwire. connect the longer red leadwire to

the red thermocouple wire and the shorter yellow

leadwire to the yellow thermocouple wire with the

screws and nuts provided. See figure

7

.

24.

locate a position on the firewall where a

3

⁄

8

”

hole can be drilled that will not interfere with

anything on either side of the firewall. pay special

attention to any wiring on the interior of the vehicle.

drill and deburr the hole.

25.

route the leadwire across the engine bay

and through the hole in the firewall. from

inside the vehicle route the leadwire to the gauge

head location. coil any excess leadwire either

under the hood or under the dash. DO NOT

SHORTEN THE LEADWIRE. The pyrometer is

calibrated for the specific length of leadwire

provided.

26.

remove the jumper wire from the terminals

on the back of the pyrometer gauge. insert

the pyrometer gauge through the panel, then slide

the u-clamp over the terminal studs. connect the

leadwire to the pyrometer, making sure that the

yellow wire is connected to the positive (+)

terminal and the red wire is connected to the

other terminal. use double nuts and lockwashers

provided to attach the leadwire to each stud and

tighten the gauge in the panel. do not loosen the

nuts that are already on the pyrometer gauge

terminal studs.

27.

install one end of the

1

⁄

8

” diameter plastic

tube provided into the nut and ferrule fitting

earlier installed in the intake plenum and tighten

the nut. be sure that the plastic tube cannot be

pulled out of the ferrule, but do not overtighten

the nut.

28.

route the plastic tube toward the firewall

and insert the tube through the hole

previously drilled. Make sure that the pyrometer

leadwire and the boost hose will not be chaffed

by the edge of the drilled hole. it may be

necessary to install a rubber grommet or use

silicone to seal the hole. route the tube toward

the gauge panel and cut to the proper length.

install the gauge with the hardware provided.

install the tube into the remaining fitting provided

at the back of the boost gauge.

29.

connect one wire from each gauge light to

a good ground location under the dash,

such as a metal support bracket where other

wires may already be grounded. connect the

remaining light wires together and to an 18 gauge

or larger wire, connected to either the headlight

circuit or the dash lighting circuit.

30.

reconnect the batteries. start the engine

and allow it to warm up. drive the vehicle

and listen for exhaust leaks or rattles. reposition

or tighten exhaust components as required. Tack

welds at each exhaust slip joint are recommended.

note: The exhaust system may smoke somewhat

at first as the grease used in the bending process

burns off the inside of the pipes.

figure 7

10

p.n. 96309 v.3.0

23.