Banks Power Ford Trucks: (Diesel ’94 - 97 7.3L Power Stroke) Power Systems- PowerPack, Stinger-Plus & Stinger '94-98 3-1_2" Exhaust User Manual

Page 17

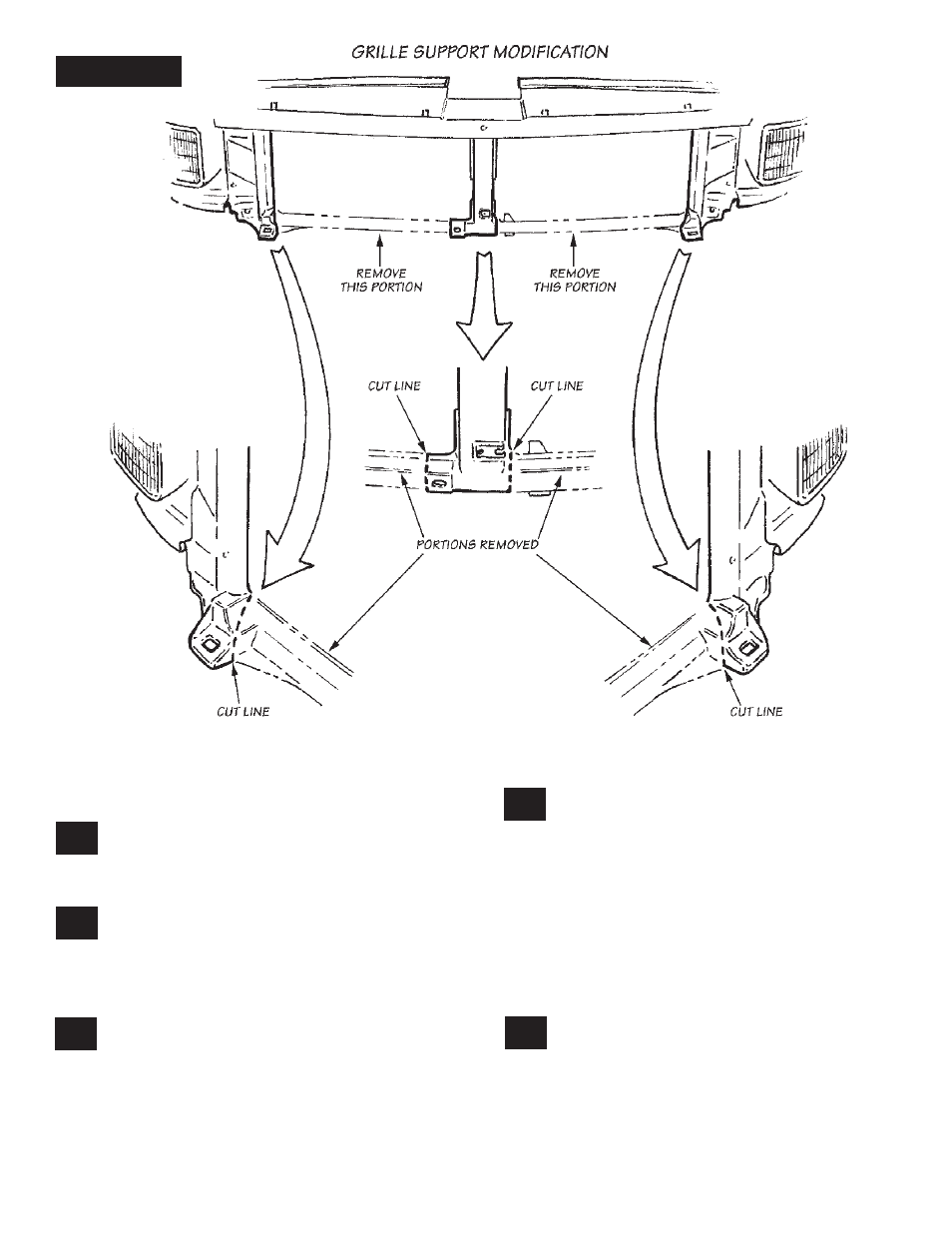

FIGURE 14

and puncture a tube in the intercooler core. There

should be a minimum of

1

⁄

4

-inch clearance between

the end of the screw and the intercooler core. If

necessary, shorten the screw.

Reinstall the headlight bezels. Be sure that

the lights are in the correct locations. If

in doubt, turn on the hazard flashers. The turn

signals will be the flashing ones.

Reinstall the grille against the grille support

with the original hardware. Reinstall the

front bumper onto the stud plates and tighten

the nuts. Once again, check the tightness of all

hose clamps to ensure the integrity of the hose

connections at high boost levels.

Clean an area that is easily visible on the

upper radiator core support with a non-oil

based solvent, such as Acetone, Mineral Spirits,

Denatured Alcohol or Lacquer Thinner. Allow to

dry and then attach the Banks E.O. sticker to the

upper radiator core support.

DYNAFACT INSTRUMENTATION INSTALLATION

GAUGE PANEL

If the gauges are being installed into an

existing gauge panel, this step may be

skipped. If gauges and a gauge panel are being

installed, choose a location where the gauges can

be easily viewed by the driver. This will typically

be to the right of the accelerator pedal, under the

lower edge of the dash panel. Mount the gauge

panel with the machine screws, washers, and

nuts provided. NOTE: Molded instrument panels

for top of dash mounting are available from Gale

Banks Engineering.

DYNAFACT PYROMETER

Install the DynaFact

®

pyrometer probe

(supplied in the pyrometer kit) in the

1

⁄

4

-inch

NPT bung located at the top of the turbine outlet

pipe. Use anti-seize compound on the threads.

Connect the lead-wire to the sensor with the

supplied screws. The wires are different lengths

to prevent cross connecting. Make sure that the

screws are tight. Slip the heat shrink tubing provided

over the wire ends.

72.

71.

70.

68.

69.

17

P.N. 96322 v.7.0