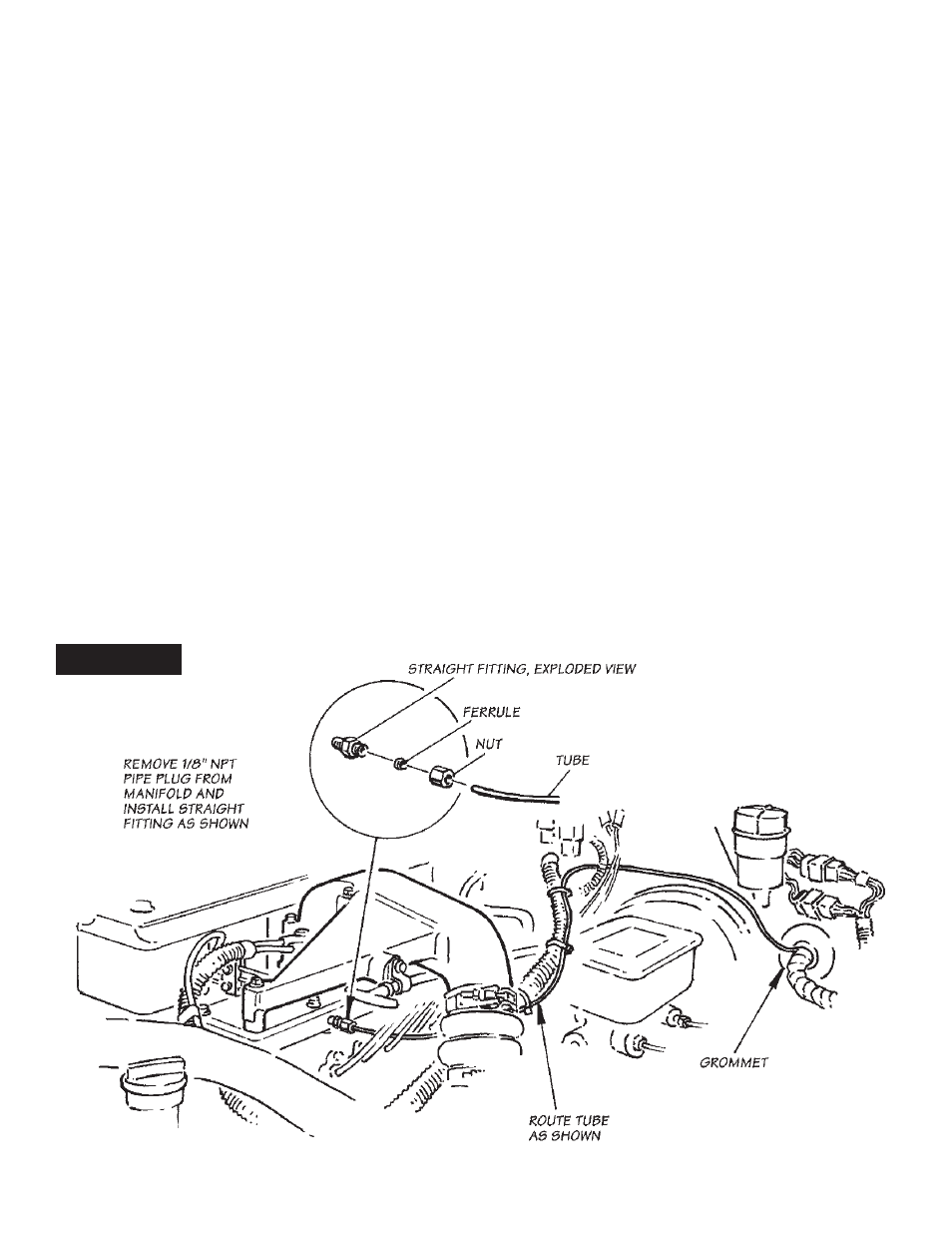

Figure 2, Cummins b5.9l – Banks Power Boost gauge User Manual

Page 4

4

p.n. 96327 v.3.0

Ford/Navistar 6.9L/7.3L IDI diesel with Banks

Sidewinder turbo — locate the

1

⁄

8

" npT threaded hole

in the pressure chamber. install the straight fitting

provided into the threaded hole with teflon thread-

sealer.

Ford/Navistar 7.3L IDI diesel with factory turbo —

locate the

1

⁄

8

" npT pipe plug in the spiral pressure

chamber. remove the plug and install the straight

fitting provided into the threaded hole with Teflon

thread-sealer.

Ford/Navistar 7.3L Power Stroke diesel with factory

turbo — locate the rubber hose connecting the intake

manifold on the passenger-side of the engine to the

manifold pressure sensor mounted on the firewall. cut

through this hose at a point three inches below the

sensor.

install the plastic tee fitting and the spring band

clamps, provided, between the cut ends of the hose.

see figure 3.

install one 90-degree elbow fitting onto the threaded

end of the tee. sparingly apply Teflon thread-sealer to

the male pipe threads, and adjust the 90-degree elbow

fitting to point toward the firewall, as shown in

figure

3

. do not over-tighten the plastic fitting. do not allow

sealant to cover the small hole in the fitting.

tUbinG installation

all gauge tubing should be routed away from heat

sources such as exhaust manifolds or piping, and away

from sharp edges. avoid sharp bends or kinks. secure

the tubing to other tubing inside the engine

compartment with cable ties.

When passing through the firewall, either make a hole

in a factory grommet or drill a hole and use a new

grommet. if a hole needs to be drilled, drill a

5

⁄

16

" hole

and deburr it on both sides, so that the tubing does not

get cut as it passes through the hole. For added

protection, wrap the tubing with several layers of

electrical tape in the area where it passes through the

hole. When drilling, check the backside to make sure

that there are no components blocking the back side of

the hole that would be damaged by drilling.

install one end of the

1

⁄

8

" diameter plastic tube,

provided, in the nut and ferrule on the adapter fitting,

and tighten the nut. check that the plastic tube cannot

be pulled out of the ferrule. do not over-tighten the nut.

route the plastic tube toward the firewall.

NOTE: If the boost gauge appears to stick after

installation, trim about

1

⁄

2

" from each end of the plastic

tube and reinstall, being careful not to over-tighten.

FIGURE 2

cUmmins b5.9l