Milton CAT 14M User Manual

Page 11

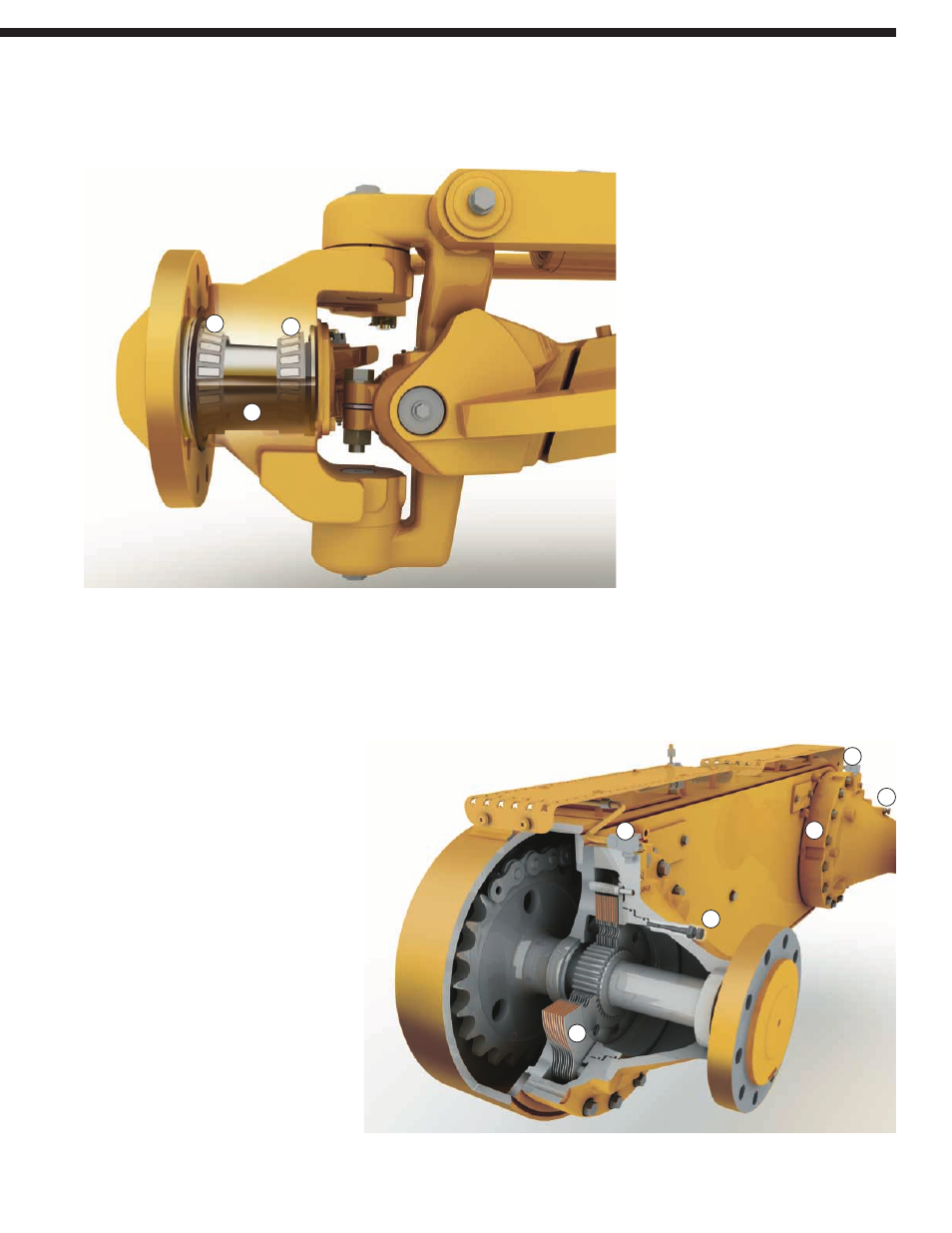

Front Axle. The Caterpillar

®

sealed

spindle keeps the bearings free from

contaminants and lubricated in a

light-weight oil (1). This durable,

low-maintenance design reduces

your owning and operating costs.

Two double tapered roller bearings (2)

support the wheel spindle. The Cat “Live

Spindle” design places the larger tapered

roller bearing outboard where the load

is greater, extending bearing life.

Gear Selection. Eight forward and

six reverse gears give the operator a

wide operating range. The specifically

designed range of gears ensures

maximum productivity in all

earthmoving applications.

Programmable Autoshift. The operator

can easily customize various shift

parameters through Cat Messenger

to match the specific application

requirement. This feature automatically

shifts the transmission at optimal points

so the operator can focus on the work,

improving safety, productivity and ease

of operation.

Inching Pedal. Allows precise control

of machine movements in any gear

with low pedal effort and excellent

modulation, critical in close-quarter

work or finish grading.

Hydraulic Brakes. The oil bathed,

multi-disc service brakes are

hydraulically actuated (1), providing

smooth predictable braking and lower

operating costs. With brakes located at

each tandem wheel, the 14M offers the

largest total brake surface area in the

industry (2), delivering dependable

stopping power and longer brake life.

Brake Serviceability and Reliability.

An easily accessible brake wear

indicator/compensator system (3)

maintains consistent brake performance

and indicates brake wear without

disassembly. This system cuts service

time and extends brake service life.

Parking Brake. The spring-applied,

hydraulically released multi-disc

parking brake can be easily serviced

without transmission removal to reduce

operating cost. A sealed, oil-cooled

design extends component life and

reduces the need for service.

11

1

2

2

3

3

1

Brake design

1

2

2

Front axle