Vishay semiconductors – C&H Technology VS-100MT1.0P.PbF Series User Manual

Page 3

VS-40MT1.0P.PbF, VS-70MT1.0P.PbF, VS-100MT1.0P.PbF Series

www.vishay.com

Vishay Semiconductors

Revision: 30-Oct-13

2

Document Number: 94538

For technical questions within your region:

,

,

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT

www.vishay.com/doc?91000

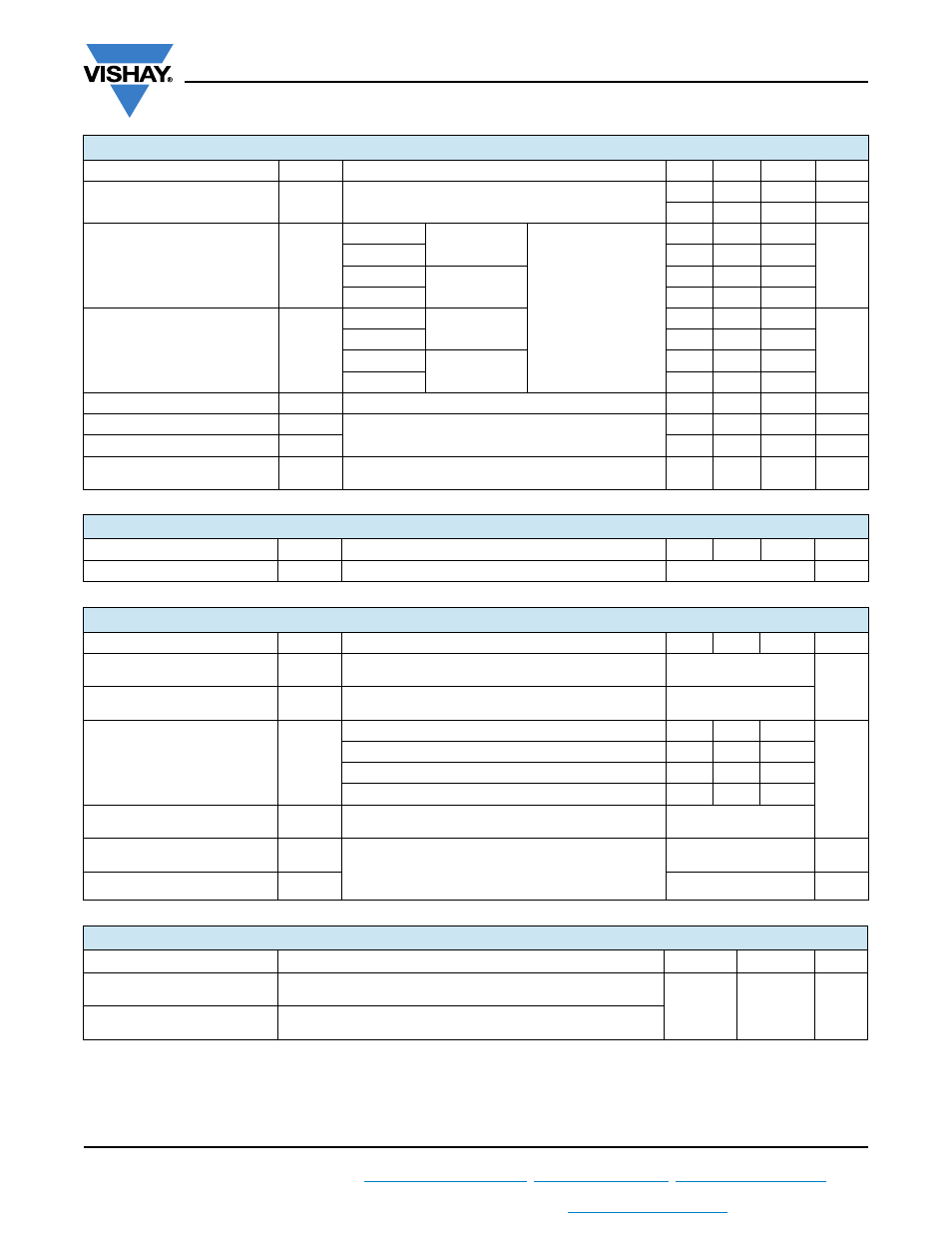

FORWARD CONDUCTION

PARAMETER SYMBOL

TEST

CONDITIONS 40MT

70MT

100MT

UNITS

Maximum DC output current

at case temperature

I

O

120° rect. to conduction angle

45

75

100

A

100

80

80

°C

Maximum peak, one cycle

forward, non-repetitive on state

surge current

I

FSM

t = 10 ms

No voltage

reapplied

Initial

T

J

= T

J

maximum

270

380

450

t = 8.3 ms

280

398

470

t = 10 ms

100 % V

RRM

reapplied

225

320

380

t = 8.3 ms

240

335

400

Maximum I

2

t for fusing

I

2

t

t = 10 ms

No voltage

reapplied

365

724

1013

A

2

s

t = 8.3 ms

325

660

920

t = 10 ms

100 % V

RRM

reapplied

253

512

600

t = 8.3 ms

240

467

665

Maximum I

2

t for fusing

I

2

t

t = 0.1 ms to 10 ms, no voltage reapplied

3650

7240

10 130

A

2

s

Value of threshold voltage

V

F(TO)

T

J

maximum

0.78

0.82

0.75

V

Slope resistance

r

t

14.8

9.5

8.1

m

Maximum forward voltage drop

V

FM

T

J

= 25 °C; t

p

= 400 μs single junction

(40MT, I

pk

= 40 A) (70MT, I

pk

= 70 A) (100MT, I

pk

= 100 A)

1.45

1.45

1.51

V

INSULATION TABLE

PARAMETER

SYMBOL

TEST CONDITIONS

40MT

70MT

100MT

UNITS

RMS insulation voltage

V

INS

T

J

= 25 °C, all terminal shorted, f = 50 Hz, t = 1 s

3500

V

THERMAL AND MECHANICAL SPECIFICATIONS

PARAMETER

SYMBOL

TEST CONDITIONS

40MT

70MT

100MT

UNITS

Maximum junction operating

temperature range

T

J

- 40 to 150

°C

Maximum storage

temperature range

T

Stg

- 40 to 125

Maximum thermal resistance,

junction to case

R

thJC

DC operation per module

0.27

0.23

0.19

K/W

DC operation per junction

1.6

1.38

1.14

120° rect. condunction angle per module

0.38

0.29

0.22

120° rect. condunction angle per junction

2.25

1.76

1.29

Maximum thermal resistance,

case to heatsink per module

R

thCS

Mounting surface smooth, flat and greased

Heatsink compound thermal conductivity = 0.42 W/mK

0.1

Mounting torque to heatsink

± 10 %

A mounting compound is recommended and the torque

should be rechecked after a period of 3 hours to allow

for the spread of the compound.

Lubricated threads

4

Nm

Approximate weight

65

g

CLEARANCE AND CREEPAGE DISTANCES

PARAMETER

TEST CONDITIONS

MT...PA

MT...PB

UNITS

Clearance

External shortest distances in air between terminals

which are not internally short circuited together

10.9

12.3

mm

Creepage distance

Shortest distance along external surface of the insulating material

between terminals which are not internally short circuited together