123 sal-a, Vishay bccomponents, Aluminum capacitors solid axial – C&H Technology 123 SAL-A User Manual

Page 11: Equivalent series resistance (esr), Test procedures and requirements

123 SAL-A

Vishay BCcomponents

Aluminum Capacitors

Solid Axial

www.vishay.com

For technical questions, contact: [email protected]

Document Number: 28355

260

Revision: 23-Jun-08

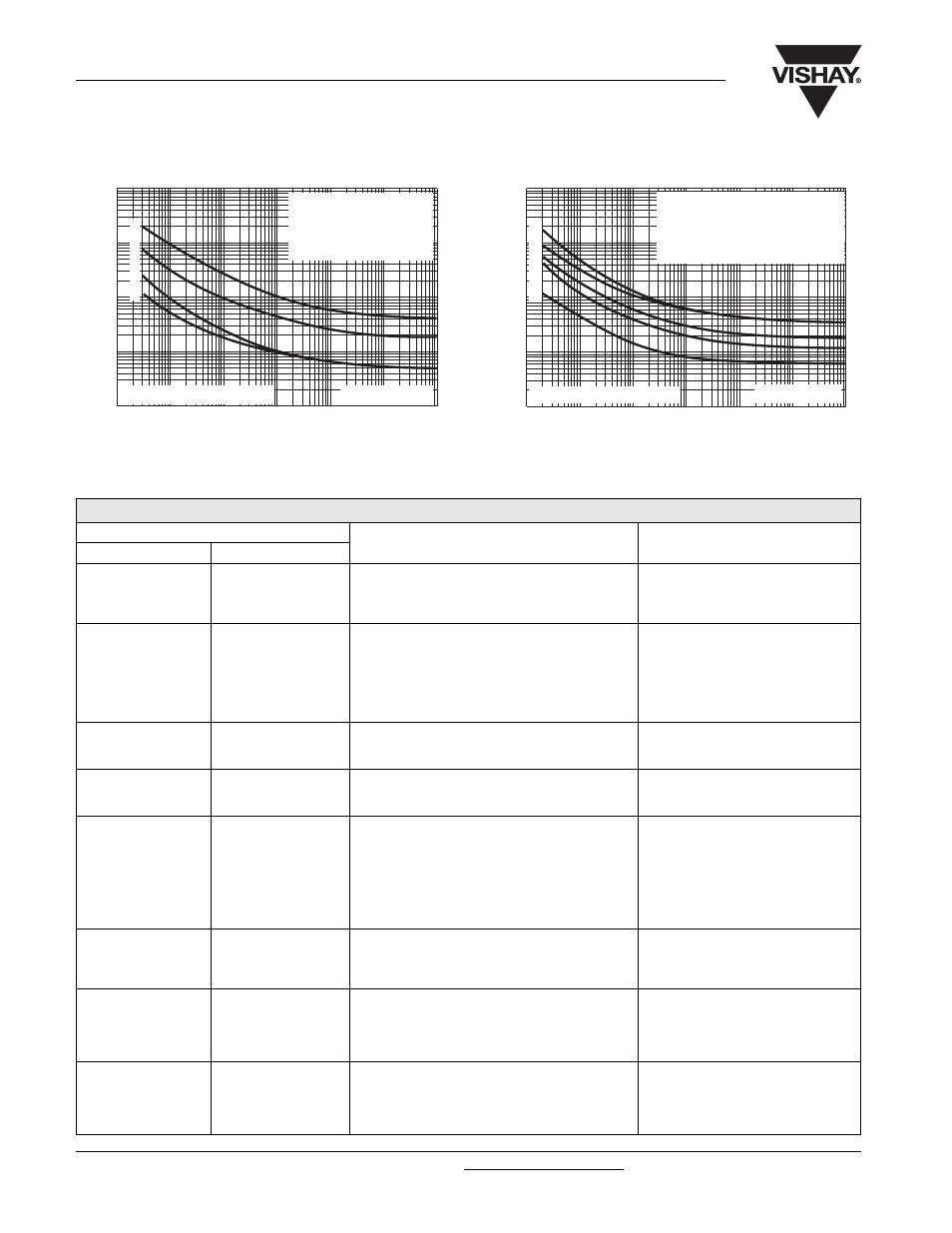

EQUIVALENT SERIES RESISTANCE (ESR)

Table 3

ESR

(Ω)

10

2

10

1

10

-1

10

-2

10

6

10

5

10

4

10

3

10

2

10

f (Hz)

1

1

2

3

4

Case Ø D x L = 9.4 x 23.3 mm

Curve 1: 68 µF, 35 and 40 V

Curve 2: 150 µF, 25 V

Curve 3: 330 µF, 10 V

Curve 4: 470 µF, 10 V

ESR at 100 Hz

Fig.28 Typical ESR as a function of ambient temperature

ESR

(Ω)

10

2

10

1

10

-1

10

-2

10

6

10

5

10

4

10

3

10

2

10

f (Hz)

1

1

2

3

4

5

Case Ø D x L = 9.4 x 23.3 mm

Curve 1: 100 µF, 35 and 40 V

Curve 2: 150 µF, 35 V

Curve 3: 220 µF, 25 V

Curve 4: 470 µF, 16 V

Curve 5: 680 µF, 10 V; 1000 µF, 6.3 V

ESR at 100 Hz

Fig.29 Typical ESR as a function of ambient temperature

TEST PROCEDURES AND REQUIREMENTS

TEST

PROCEDURE

(quick refeerence)

REQUIREMENTS

NAME OF TEST

REFERENCE

Endurance

IEC 60384-4/

EN130300

subclause 4.13

T

amb

= 125 °C;

U

R

= 6.3 to 25 V with U

R

applied;

U

R

= 35 and 40 V with U

C

applied;

10 000 hours

ΔC/C: ± 10 %

tan

δ ≤ 1.2 x spec. limit

Z

≤ 1.2 x spec. limit

I

L5

≤ spec. limit

Useful life

CECC 30302

subclause 1.8.1

T

amb

= 125 °C; I

R

applied and

U

R

= 6.3 to 25 V with U

R

applied;

U

R

= 35 and 40 V with U

C

applied;

20 000 hours

ΔC/C: ± 15 %

tan

δ ≤ 1.5 x spec. limit

Z

≤ 1.5 x spec. limit

I

L5

≤ spec. limit

no short or open circuit,

no visible damage

total failure percentage:

< 1 %

Shelf life

(storage at high

temperature)

IEC 60384-4/

EN130300

subclause 4.17

T

amb

= 125 °C; no voltage applied;

500 hours

ΔC/C: ± 10 %

tan

δ ≤ 1.2 x spec. limit

I

L5

≤ 1 x spec. limit

Charge and

discharge

IEC 60384-4-2

subclause 9.21

10

6

cycles without series resistance:

0.5 s to U

R

;

0.5 s to ground

ΔC/C: ± 5 %

no short or open circuit,

no visible damage

Shock

IEC 60068-2-27

test Ea

half-sine or saw tooth pulse shape; 50 g; 11 ms;

3 successive shocks in each direction of

3 mutually perpendicular axes;

no voltage applied

no intermittent contacts

no breakdown

no open circuiting

no mechanical damage

ΔC/C: ± 5 %

tan

δ ≤ 1.2 x spec. limit

Z

≤ 1.2 x spec. limit

I

L5

≤ 1.5 x spec. limit

Severe rapid change

of temperature

100 cycles of 1 hour duration, each with

30 minutes at - 40 °C and + 125 °C

ΔC/C: ± 25 %

tan

δ ≤ 1.5 x spec. limit

Z

≤ 2.0 x spec. limit

I

L5

≤ 1 x spec.limit

Solvent resistance

IEC 60068-2-45,

test XA

IEC 60653

immersion:

5 ± 0.5 minutes with or without ultrasonic

at 55 ± 5 °C

solvents: demineralized water and/or calgonite

solution (20 g/l)

visual appearance not affected

Passive flammability

IEC 60695-2-2

capacitor mounted to a vertical printed-circuit

board, one flame on capacitor body;

T

amb

= 20 to 25 °C;

test duration = 20 s

after removing the test flame from the

capacitor, the capacitor must not

continue to burn for more than 15 s;

no burning particles must drop from

the sample