Vishay sfernice, Enamelled wirewound power rsistors axial leads – C&H Technology RWM User Manual

Page 3

RWM

Enamelled Wirewound Power Rsistors

Axial Leads

Vishay Sfernice

Document Number: 50008

For technical questions, contact: [email protected]

www.vishay.com

Revision: 11-Dec-06

39

OVERLOAD

Heavy overloads can be endured in the form of short pulses < 0.1 s. Particular requirements should be submitted to Vishay

Sfernice, specifying peak voltage, cycle and environmental conditions.

RECOMMENDATIONS FOR USE

Since these components are high dissipation power resistors, customers are advised to use a high melting point solder.

For low ohmic values, the measurement becomes critical and the connecting wires resistance is to be included. The value is

measured at 5 mm from the resistor body.

Group Mounting

In a still atmosphere, a distance between axes equal to five times the resistor’s diameter is recommended.

Cabinet Mounting

• Unventilated box: dissipation should be reduced (see dimensional drawing).

• Forced ventilation: if conditions are appropriate, dissipation may be doubled or even trebled.

• In any case: the surface temperature at the hottest point should not exceed 450 °C.

These aspects should be considered by the end user.

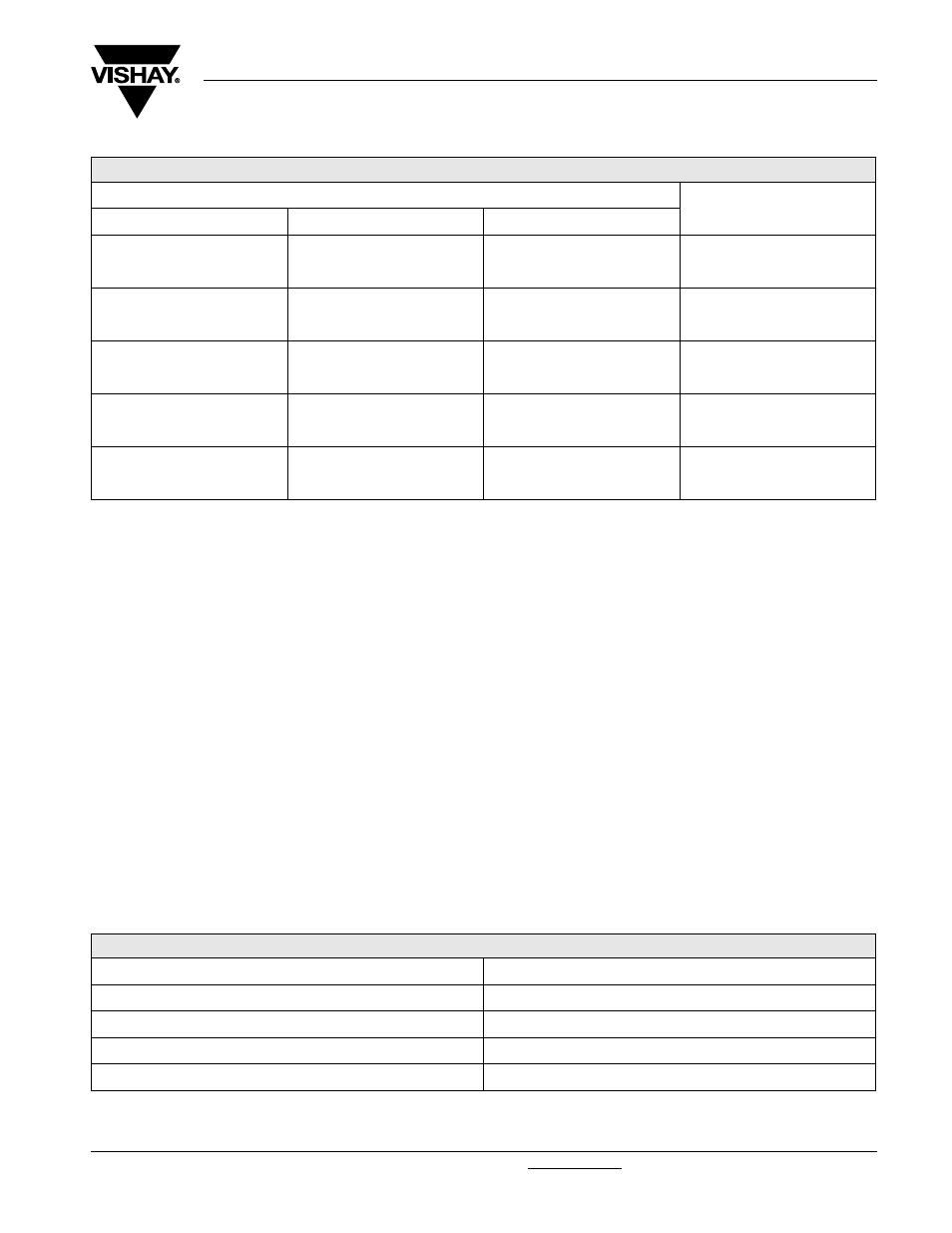

PERFORMANCE

CECC 40201 - EN 140-201

TYPICAL DRIFTS

TESTS

CONDITIONS

REQUIREMENTS

Short Time Overload

10 Pr during 10 s

25 °C ambient

± (2 %

+ 0.1

Ω)

± (0.5 %

+ 0.05

Ω)

Temperature Cycling

- 55 °C + 200 °C

± (1 %

+ 0.05

Ω)

± (0.5 %

+ 0.05

Ω)

Humidity (Steady State)

56 days

40 °C Ambient - R.H. 95 %

± (5 %

+ 0.1

Ω)

± (0.5 %

+ 0.05

Ω)

Terminal Strength

Tensile test: 20 N

2 successive bending

2 full rotations of 180°

± (1 %

+ 0.05

Ω)

± (0.1 %

+ 0.05

Ω)

Load Life

1000 h at Pr

90/30 Cycle

25 °C ambient

± (5 %

+ 0.1

Ω)

± (1.5 %

+ 0.05

Ω)

ELECTRICAL SPECIFICATIONS

Tolerance Standard

± 5 %

On request

± 1 % to ± 10 %

Temperature Coefficient + 75 ppm/°C typical

Dielectric Withstanding Voltage NF EN 140000

500 VRMS - 1 minute - 10 mA

Inductance

non inductive (Ayrton-Perry) winding available