Vishay dale, Wirewound resistors, commercial coated, axial lead – C&H Technology CW User Manual

Page 2

CW

Wirewound Resistors, Commercial Coated, Axial Lead

Vishay Dale

Document Number: 30215

For technical questions, contact: [email protected]

www.vishay.com

Revision: 10-Dec-07

21

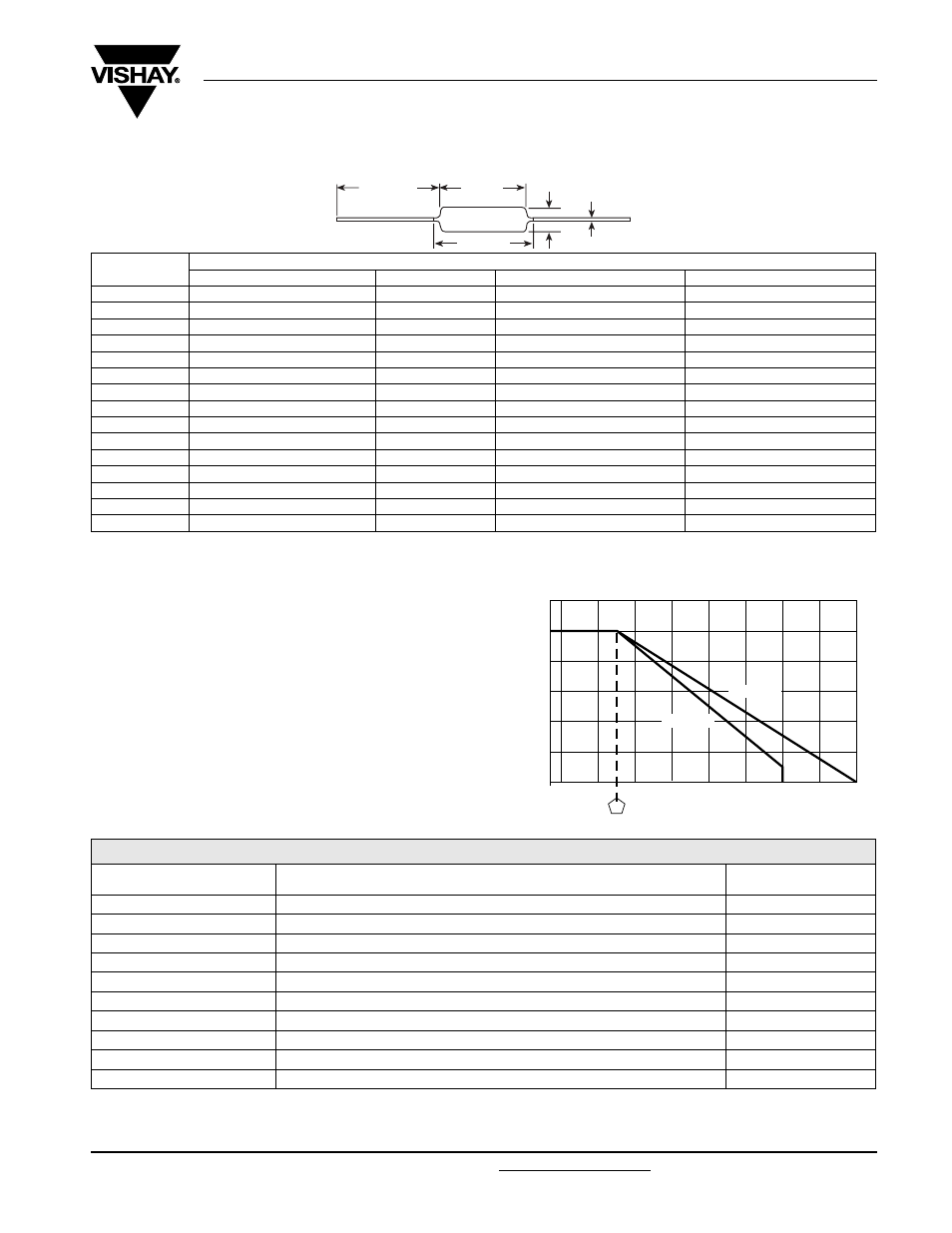

DIMENSIONS in inches [millimeters]

Notes

(1)

On some standard reel pack methods, the leads may be trimmed to a shorter length than shown

(2)

B (maximum) dimension is clean lead to clean lead

MATERIAL SPECIFICATIONS

Element: Copper-nickel alloy or nickel-chrome alloy,

depending on resistance value

Core: Ceramic: Steatite or alumina, depending on physical

size

Coating: Special high temperature silicone

Standard Terminals: Tinned Copperweld

®

End Caps: Stainless steel

Part Marking: DALE, model, wattage

(3)

, value, tolerance,

date code

Note

(3)

Wattage marked on resistor will be “V” characteristic, CW1/2 will

not be marked with wattage

Note

(4)

All

ΔR figures shown are maximum, based upon testing requirements per MIL-PRF-26 at a maximum operating temperature of + 350 °C.

ΔR maximum figures are considerably lower when tested at a maximum operating temperature of + 250 °C.

MODEL

DIMENSIONS in inches [millimeters]

A

B (maximum)

(2)

C

D

CW1/2

0.250 ± 0.031 [6.35 ± 0.787]

0.281 [7.14]

0.085 ± 0.020 [2.16 ± 0.508]

0.020 ± 0.002 [0.508 ± 0.051]

CW001

0.406 ± 0.031 [10.31 ± 0.787]

0.437 [11.10]

0.094 ± 0.031 [2.39 ± 0.787]

0.020 ± 0.002 [0.508 ± 0.051]

CW01M

0.285 ± 0.025 [7.24 ± 0.635]

0.311 [7.90]

0.110 ± 0.015 [2.79 ± 0.381]

0.020 ± 0.002 [0.508 ± 0.051]

CW002

0.625 ± 0.062 [15.87 ± 1.57]

0.765 [19.43]

0.250 ± 0.032 [6.35 ± 0.813]

0.040 ± 0.002 [1.02 ± 0.051]

CW02M

0.500 ± 0.062 [12.70 ± 1.57]

0.562 [14.27]

0.185 ± 0.015 [4.70 ± 0.381]

0.032 ± 0.002 [0.813 ± 0.051]

CW02B

0.562 ± 0.062 [14.27 ± 1.57]

0.622 [15.80]

0.188 ± 0.032 [4.78 ± 0.813]

0.032 ± 0.002 [0.813 ± 0.051]

CW02B...13

0.500 ± 0.062 [12.70 ± 1.57]

0.563 [14.30]

0.188 ± 0.032 [4.78 ± 0.813]

0.032 ± 0.002 [0.813 ± 0.051]

CW02C

0.500 ± 0.062 [12.70 ± 1.57]

0.593 [15.06]

0.218 ± 0.032 [5.54 ± 0.813]

0.040 ± 0.002 [1.02 ± 0.051]

CW02C...14

0.500 ± 0.062 [12.70 ± 1.57]

0.593 [15.06]

0.218 ± 0.032 [5.54 ± 0.813]

0.032 ± 0.002 [0.813 ± 0.051]

CW005

0.875 ± 0.062 [22.22 ± 1.57]

1.0 [25.40]

0.312 ± 0.032 [7.92 ± 0.813]

0.040 ± 0.002 [1.02 ± 0.051]

CW005...2

0.875 ± 0.062 [22.22 ± 1.57]

1.0 [25.40]

0.250 ± 0.032 [6.35 ± 0.813]

0.032 ± 0.002 [0.813 ± 0.051]

CW005...3

0.875 ± 0.062 [22.22 ± 1.57]

1.0 [25.40]

0.312 ± 0.032 [7.92 ± 0.813]

0.032 ± 0.002 [0.813 ± 0.051]

CW007

1.218 ± 0.062 [30.94 ± 1.57]

1.281 [32.54]

0.312 ± 0.032 [7.92 ± 0.813]

0.040 ± 0.002 [1.02 ± 0.051]

CW010

1.781 ± 0.062 [45.24 ± 1.57]

1.875 [47.62]

0.375 ± 0.032 [9.52 ± 0.813]

0.040 ± 0.002 [1.02 ± 0.051]

CW010...3

1.781 ± 0.062 [45.24 ± 1.57]

1.875 [47.62]

0.375 ± 0.032 [9.52 ± 0.813]

0.032 ± 0.002 [0.813 ± 0.051]

D

C

1.50 [38.10]

(1)

minimum

A

B

RATED POWER

IN

%

AMBIENT TEMPERATURE IN °C

25

0

20

40

60

80

100

120

- 65

150

350

50

250

0

- 50

CHAR. U

Derating

CHAR. V

PERFORMANCE

(4)

TEST

CONDITIONS OF TEST

TEST LIMITS

(CHARACTERISTIC V)

Thermal Shock

Rated power applied until thermally stable, then a minimum of 15 min at - 55 °C

± (2.0 % + 0.05

Ω) ΔR

Short Time Overload

5 x rated power (3.75 W and smaller), 10 × rated power (4 W and larger) for 5 s

± (2.0 % + 0.05

Ω) ΔR

Dielectric Withstanding Voltage

1000 V

rms

, 1 min

± (0.1 % + 0.05

Ω) ΔR

Low Temperature Storage

- 65 °C for 24 h

± (2.0 % + 0.05

Ω) ΔR

High Temperature Exposure

250 h at + 350 °C

± (4.0 % + 0.05

Ω) ΔR

Moisture Resistance

MIL-STD-202 Method 106, 7b not applicable

± (2.0 % + 0.05

Ω) ΔR

Shock, Specified Pulse

MIL-STD-202 Method 213, 100 g’s for 6 ms, 10 shocks

± (0.2 % + 0.05

Ω) ΔR

Vibration, High Frequency

Frequency varied 10 to 2000 Hz, 20 g peak, 2 directions 6 h each

± (0.2 % + 0.05

Ω) ΔR

Load Life

2000 h at rated power, + 25 °C, 1.5 h “ON”, 0.5 h “OFF”

± (3.0 % + 0.05

Ω) ΔR

Terminal Strength

5 to 10 s 10 pound pull test; torsion test - 3 alternating directions, 360 °C each

± (1.0 % + 0.05

Ω) ΔR