Lps 1100, Vishay sfernice – C&H Technology LPS1100 User Manual

Page 4

LPS 1100

www.vishay.com

Vishay Sfernice

Revision: 14-Jun-12

3

Document Number: 50059

For technical questions, contact:

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT

www.vishay.com/doc?91000

Note

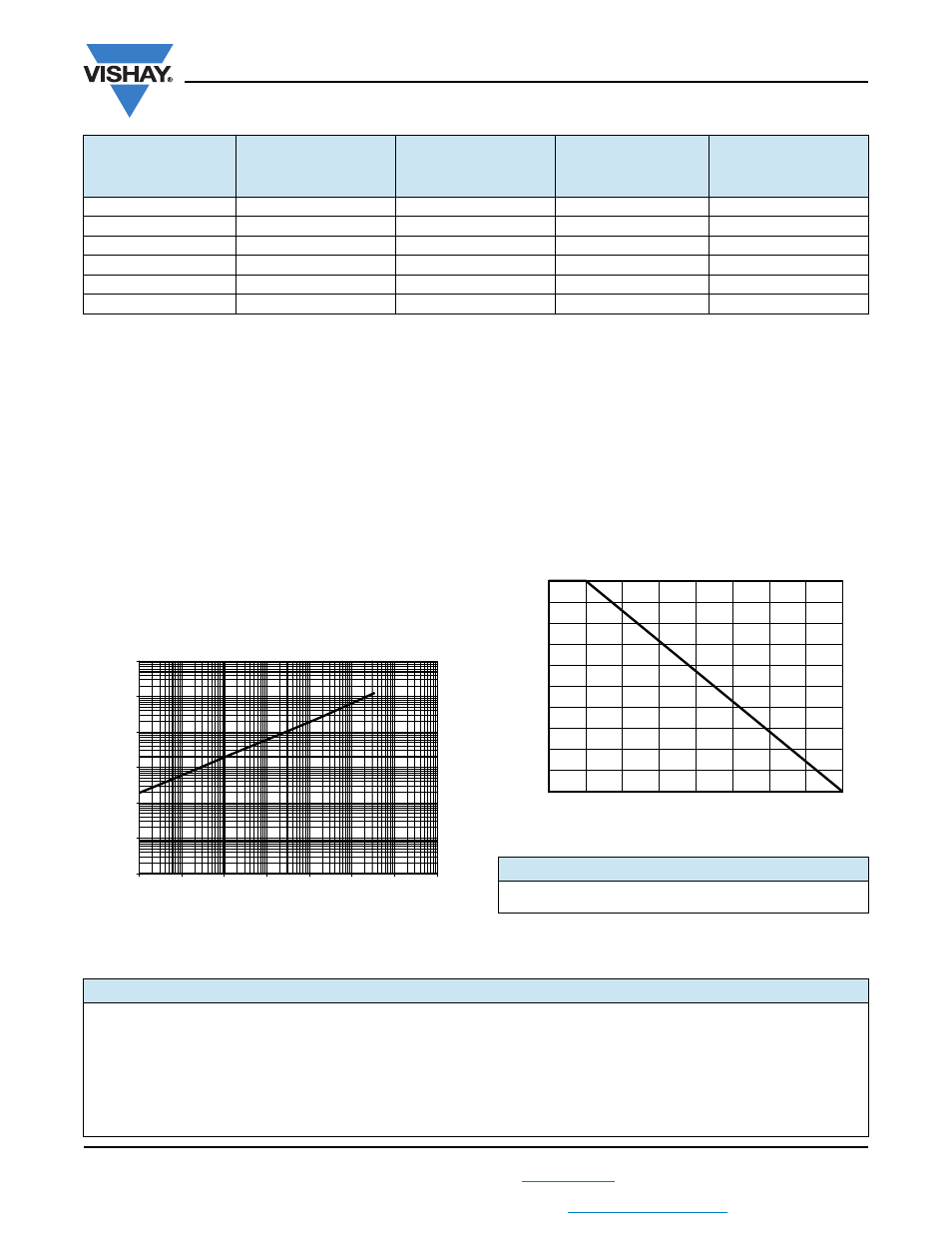

• Configuration 1: Water cooling heatsink (CP15 from Lytron (304 mm x 95.3 mm x 8 mm) with water flow rate 4LPM and thermal grease Si340

from BlueStar Silicones

Configuration 2: Air cooling heatsink P207/250 from Semikron (250 mm x 200 mm x 72 mm) and thermal grease Si340 from BlueStar

Silicones

Configuration 3: Water cooling heatsink (CP15 from Lytron (304 mm x 95.3 mm x 8 mm) with water flow rate 4LPM and thermal pad

Q-pad II from Berquist

Configuration 4: Air cooling heatsink P207/250 from Semikron (250 mm x 200 mm x 72 mm) and thermal pad Q-pad II from Berquist

OVERLOAD

In any case the applied voltage must be lower than

U

I

= 6600 V.

Short time overload: 2 x Pr/10 s for heatsink with

R

th(h-a)

0.26 °C/W (maximum power: 700 W) and 1.6 x

Pr/1 s for heatsink with 0.26 °C/W > R

th(h-a)

0.059 °C/W

(maximum power: 1800 W).

Accidental overload: The values indicated on the following

graph are applicable to resistors in air or mounted onto a

heatsink.

ENERGY CURVE

MARKING

Series, style, ohmic value (in

), tolerance (in %),

manufacturing date, Vishay Sfernice trademark.

POWER RATING

The temperature of the case should be maintained within

the limit specified in the following figure. To optimize

the thermal conduction, contacting surfaces should be

coated with silicone grease or thermal film, and heatsink

mounting screws tightened to 2 Nm.

CONFIG. 1:

WATER COOLING

HEATSINK CP15 AND

THERMAL GREASE SI340

CONFIG. 2:

AIR COOLING

HEATSINK P207/250 AND

THERMAL GREASE SI340

CONFIG. 3:

WATER COOLING

HEATSINK CP15 AND

THERMAL PAD Q-PAD II

CONFIG. 4:

AIR COOLING

HEATSINK P207/250 AND

THERMAL PAD Q-PAD II

Power Dissipation (W)

1100

350

650

285

T° Resistive Element (°C)

200

200

200

200

R

th(j-c)

max. (°C/W)

0.039

0.039

0.039

0.039

R

th(c-h)

typ. (°C/W)

0.070

0.201

0.187

0.315

R

th(h-a)

max. (°C/W)

0.059

0.260

0.059

0.260

Fluid T° (°C)

15 (water)

25 (air)

15 (water)

25 (air)

ENERGY IN J

0.01

0.1

1

10

100

10 000

OVERLOAD DURATION IN s

1

10

-7

10

-6

10

-5

10

-4

10

-3

10

-2

10

-1

1000

PACKAGING

Box of 15 units

0

20

40

60

80

100

RA

TED PO

WER IN %

HEATSINK TEMPERATURE IN °C

200

0

175

150

125

100

75

50

25

ORDERING INFORMATION

LPS

1100

1 k

± 1 %

xxx

BO15

e

MODEL

STYLE

RESISTANCE

VALUE

TOLERANCE

CUSTOM

DESIGN

PACKAGING

LEAD (Pb)-FREE

± 1 %

± 2 %

± 5 %

± 10 %

Optional on

request:

special TCR,

shape, etc.