VEGA VEGAFLEX 83 4 … 20 mA_HART two-wire Rod and cable probe - PFA insulated With SIL qualification User Manual

Page 80

80

12 Supplement

VEGAFLEX 83 • 4 … 20 mA/HART two-wire

44228-EN-130823

L

2 mm

(0.079")

0

-2 mm

(-0.079

")

15 mm

(0.591")

-15 mm

(-0.591

"

)

0,35 m

(13.78

")

0,2 m

(7.874

"

)

0,2 m

(7.874

")

0,05 m

(1.969

")

1

1

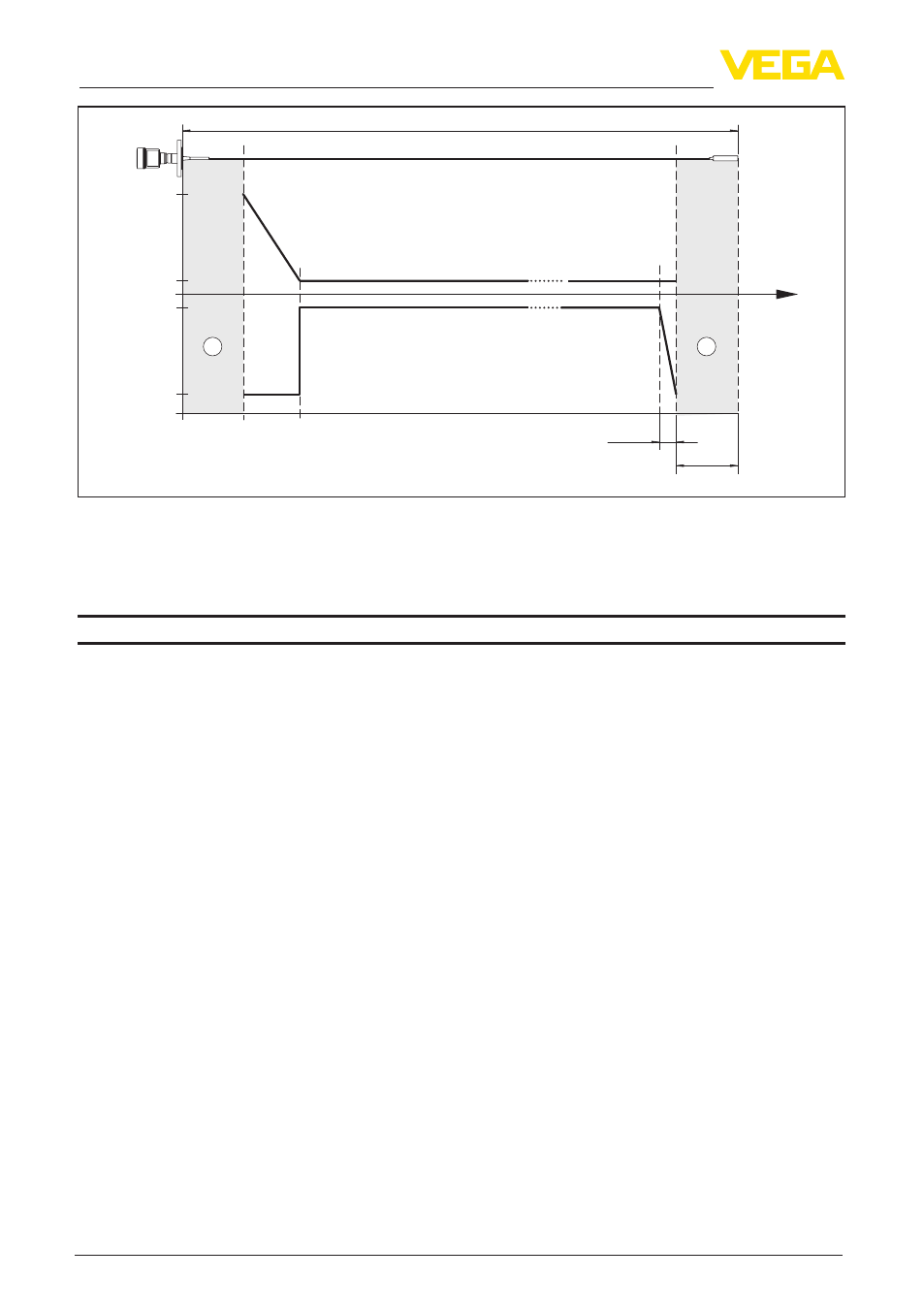

Fig. 45: Deviation VEGAFLEX 83 in cable version (coated) in oil

1 Dead band - no measurement possible in this area

L Probe length

Repeatability

≤ ±1 mm

Accuracy (according to DIN EN 60770-1)

Process reference conditions according to DIN EN 61298-1

Ʋ Temperature

+18 … +30 °C (+64 … +86 °F)

Ʋ Relative humidity

45 … 75 %

Ʋ Air pressure

+860 … +1060 mbar/+86 … +106 kPa

(+12.5 … +15.4 psig)

Installation reference conditions

Ʋ Min. distance to installations

> 500 mm (19.69 in)

Ʋ Vessel

metallic, ø 1 m (3.281 ft), centric installation, process

fitting flush with the vessel ceiling

Ʋ Medium

Water/Oil (dielectric constant ~2.0)

7)

Ʋ Installation

Probe end does not touch the vessel bottom

Sensor parameter adjustment

No gating out of false signals carried out

Typical deviation - Interface measure-

ment

± 5 mm (0.197 in)

Typical deviation - Total level interface

measurement

See following diagrams

Typical deviation - Level measurement

8)9)

See following diagrams

7)

With interface measurement = 2.0

8)

Depending on the installation conditions, there can be deviations which can be rectified with an adaptation of

the adjustment or a change of the measured value offset in the DTM service mode

9)

The dead bands can be optimizes by a false signal suppression.