3 double blocking valve according to din16272 – VEGA Mounting accessories, pressure measurement technology User Manual

Page 12

The scope of delivery encompasses:

l

Double blocking valve

l

This supplementary instructions

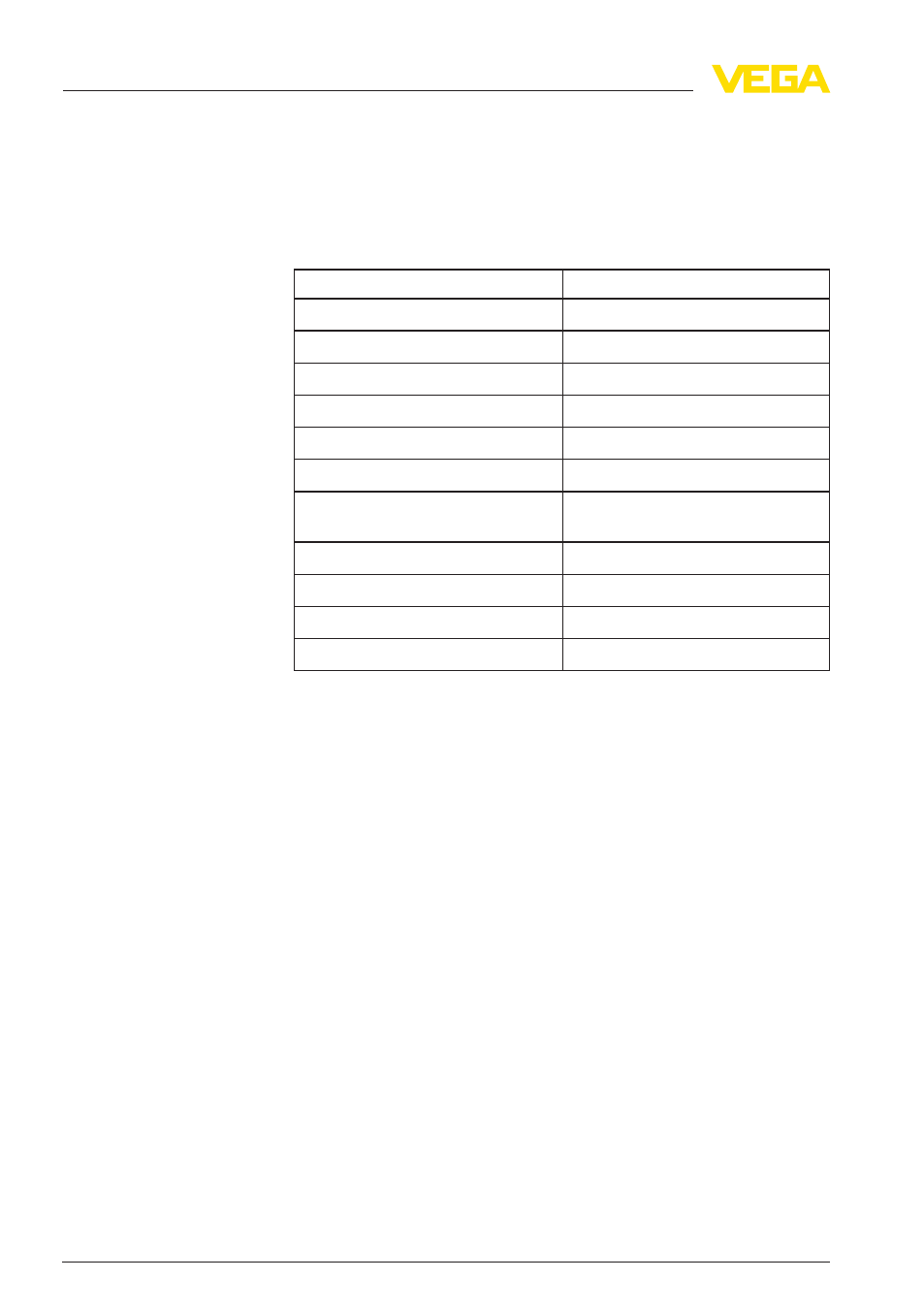

Feature

Feature

Art. no.

BARVALVE.F …

Material housing

316Ti

Material valve seal packing

PTFE

Input

Pin ½ NPT

Output

Sleeve ½ NPT

Ventilation/Test connection

¼ NPT

, with closing screw

Pressure stage/Max. permissible

pressure

PN 420/420 bar

Max. permissible pressure at 80 °C

420 bar

Max. permissible pressure at 200 °C

320 bar

Temperature max.

200 °C

Weight

approx. 0.9 kg

Rust, sand or similar pollution int he medium, especially when rinsing

the system before the first setup, can cause buildup around the valve

seat. This can cause leakage of the valve seat.

When the prepressed packing is stored for a longer time, its sealing

ability can deteriorate. If necessary, the seal must be retightened at the

time of setup. The procedure is described in chapter "Maintenance

and fault rectification".

5

.3 Double blocking valve according to DIN 16272

The double blocking valve according to DIN 16270 enables simple

mounting, setup and dismounting of a pressure transmitter with

process fitting G½.

The process valve separates the pressure transmitter from the

process. The ventilation/test valves enables two functions with closed

process valve:

l

Ventilation of the pressure transmitter

l

Checking the pressure transmitter via a connected pressure

calibrator.

Scope of delivery

Technical data

Mounting and setup in-

structions

Storage

Application area/Func-

tion

12

Mounting accessories, pressure measurement technology

5 Blocking valves

43478

-EN

-121018