VEGA VEGAPULS 62 (≥ 2.0.0 - ≥ 4.0.0) 4 … 20 mA_HART - two-wire User Manual

Page 68

68

11 Supplement

VEGAPULS 62 • 4 … 20 mA/HART - two-wire

36503-EN-121011

Temperature drift - Digital output

±3 mm/10 K relating to the max. measuring range or

max. 10 mm

Additional deviation through strong, high

frequency electromagnetic fields acc. to

EN 61326

< ±50 mm

Specifications apply also to the current output

Temperature drift - Current output

±0.03 %/10 K relating to the 16 mA span max. ±0.3 %

Deviation on the current output by ana-

logue/digital conversion

< ±15 µA

Deviation on the current output due to

strong, high frequency electromagnetic

fields acc. to EN 61326

< ±150 µA

Influence of the superimposed gas and pressure to the accuracy

The propagation speed of the radar impulses in gas or vapour above the medium is reduced by

high pressure. This effect depends on the superimposed gas or vapour and is especially large at

low temperatures.

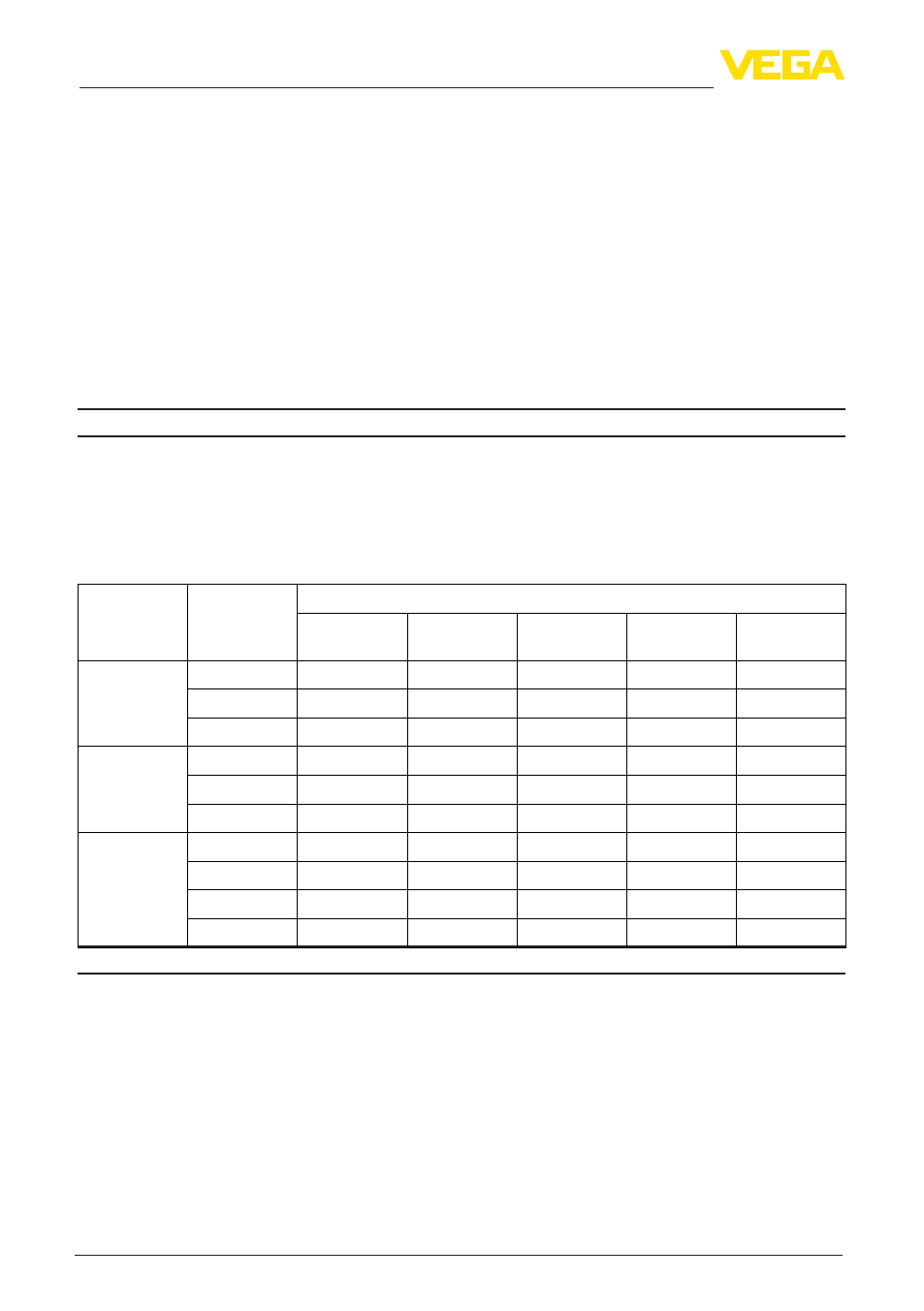

The following table shows the resulting deviation for some typical gases and vapours. The specified

values refer to the distance. Positive values mean that the measured distance is too large, negative

values that the measured distance is too small.

Gas phase

Temperature

Pressure

1 bar

(14.5 psig)

10 bar

(145 psig)

50 bar

(725 psig)

100 bar

(1450 psig)

200 bar

(2900 psig)

Air

20 °C/68 °F

0.00 %

0.22 %

1.2 %

2.4 %

4.9 %

200 °C/392 °F -0.01 %

0.13 %

0.74 %

1.5 %

3.0 %

400 °C/752 °F -0.02 %

0.08 %

0.52 %

1.1 %

2.1 %

Hydrogen

20 °C/68 °F

-0.01 %

0.10 %

0.61 %

1.2 %

2.5 %

200 °C/392 °F -0.02 %

0.05 %

0.37 %

0.76 %

1.6 %

400 °C/752 °F -0.02 %

0.03 %

0.25 %

0.53 %

1.1 %

Steam (satu-

rated steam)

100 °C/212 °F 0.26 %

-

-

-

-

180 °C/356 °F 0.17 %

2.1 %

-

-

-

264 °C/507 °F 0.12 %

1.44 %

9.2 %

-

-

366 °C/691 °F 0.07 %

1.01 %

5.7 %

13.2 %

76.0 %

Characteristics and performance data

Measuring frequency

K-band (26 GHz technology)

Measuring cycle time

Ʋ Standard electronics approx.

450 ms

Ʋ Electronics with increased sensitivity

approx.

700 ms

Step response time

2)

≤ 3 s

2)

Time span after a sudden measuring distance change by max. 0.5 m in liquid applications, max 2 m with bulk

solids applications, until the output signal has taken for the first time 90 % of the final value (IEC 61298-2).