4 rectify faults – VEGA VEGAPULS SR 68 Profibus PA User Manual

Page 61

61

9 Diagnosis, Asset Management and service

VEGAPULS SR 68 • Profibus PA

38296-EN-130624

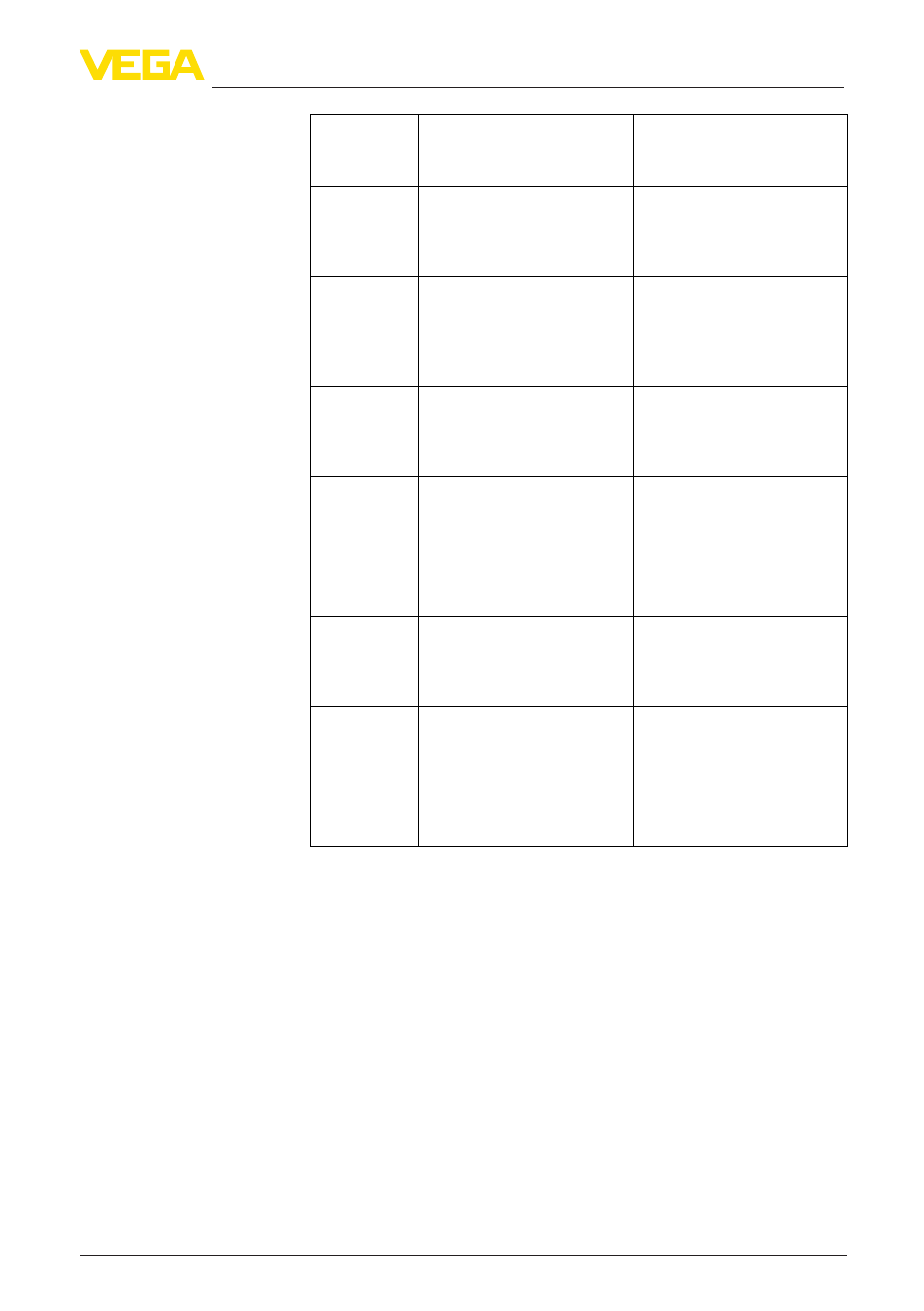

Code

Text mes-

sage

Cause

Rectification

M500

Error with the

reset delivery

status

– With the reset to delivery

status, the data could not

be restored

– Repeat reset

– Load XML file with sensor

data into the sensor

M501

Error in the

non-active

linearization

table

– Hardware error EEPROM

– Exchanging the electronics

– Send instrument for repair

M502

Error in the

diagnosis

memory

– Hardware error EEPROM

– Exchanging the electronics

– Send instrument for repair

M503

Reliability too

low

– The echot/noise ratio is the

small for a reliable meas-

urement

– Check installation and

process conditions

– Clean the antenna

– Change polarisation direc-

tion

– Use instrument with higher

sensitivity

M504

Error on an

device inter-

face

– Hardware defect

– Check connections

– Exchanging the electronics

– Send instrument for repair

M505

No echo avail-

able

– Level echo can no longer

be detected

– Clean the antenna

– Use a more suitable

antenna/sensor

– Remove possible false

echoes

– Optimize sensor position

and orientation

9.4 Rectify faults

The operator of the system is responsible for taking suitable meas-

ures to rectify faults.

The first measures are:

•

Evaluation of fault messages, for example via the display and

adjustment module

•

Checking the output signal

•

Treatment of measurement errors

Further comprehensive diagnostics options offer a PC with the soft-

ware PACTware and the suitable DTM. In many cases, the reasons

can be determined in this way and faults can be rectified.

The below tables show typical examples for application-relevant

measurement errors with bulk solids. There are two measurement

errors:

Reaction when malfunc-

tions occur

Procedure for fault recti-

fication

Treatment of measure-

ment errors with bulk

solids