Measurement error during filling – VEGA VEGAPULS 63 (≥ 2.0.0 - ≥ 4.0.0) 4 … 20 mA_HART two-wire User Manual

Page 55

55

9 Diagnosis, Asset Management and service

VEGAPULS 63 • 4 … 20 mA/HART two-wire

36511-EN-130228

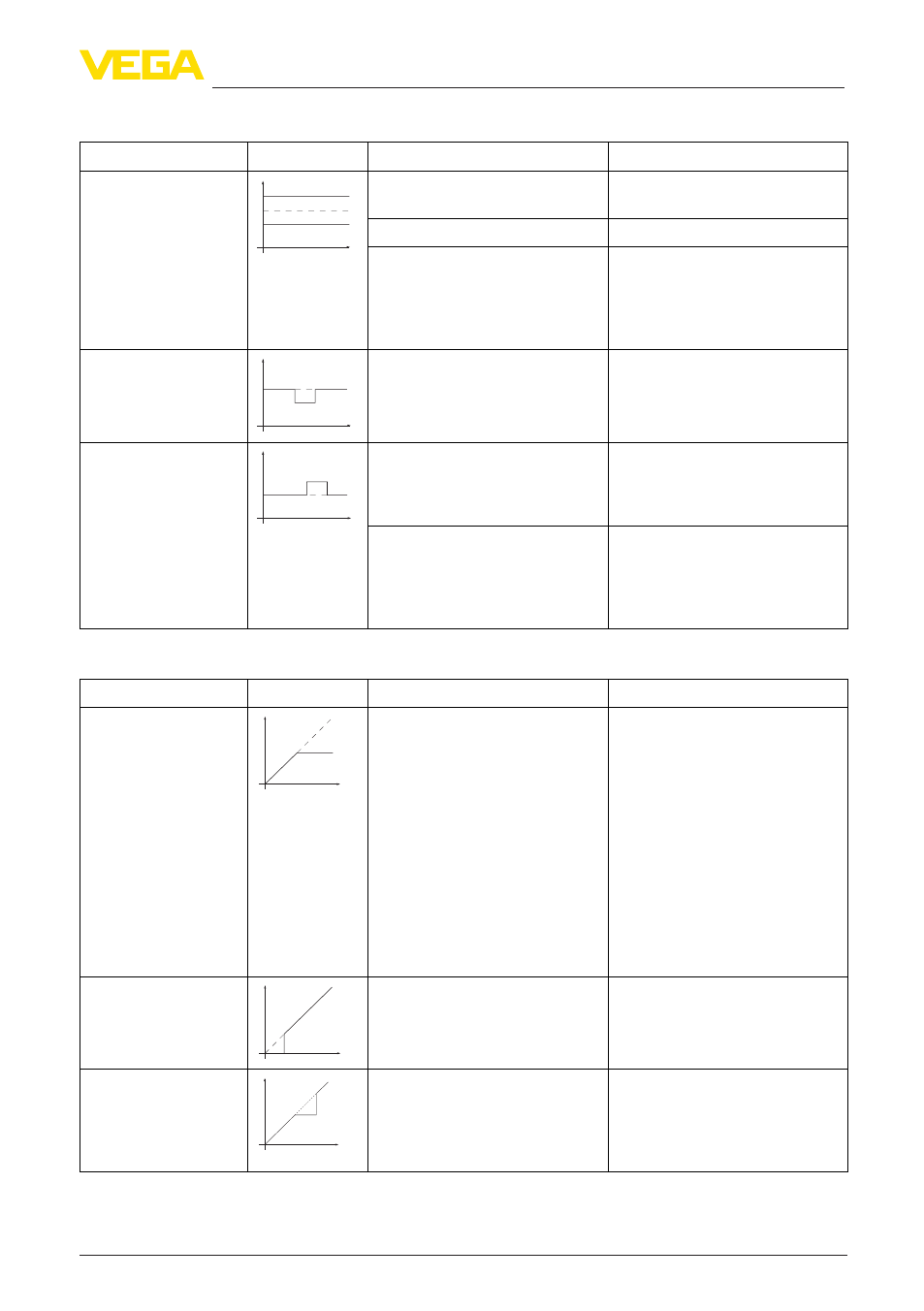

Measurement error with constant level

Fault description

Error pattern

Cause

Rectification

1. Measured value

shows a too low or too

high level

Level

time

0

– Min./max. adjustment not

correct

– Adapt min./max. adjustment

– Wrong linearization curve

– Adapt linearization curve

– Installation in a bypass tube or

standpipe, hence running time

error (small measurement error

close to 100 %/large error close

to 0 %)

– Check parameter "Application"

with respect to vessel form,

adapt if necessary (bypass,

standpipe, diameter)

2. Measured value

jumps towards 0 %

Level

time

0

– Multiple echo (vessel top,

product surface) with amplitude

higher than the level echo

– Check parameter "Application",

especially vessel top, product

type, dished end, high dielectric

figure, adapt if necessary

3. Measured value

jumps towards 100 %

Level

time

0

– Due to the process, the ampli-

tude of the product echo sinks

– A false signal suppression was

not carried out

– Carry out false signal suppres-

sion

– Amplitude or position of a

false echo has changed (e.g.

condensation, buildup); false

signal suppression no longer

matches

– Determine the reason for the

changed false signals, carry out

false signal suppression, e.g.

with condensation

Measurement error during filling

Fault description

Error pattern

Cause

Rectification

4. Measured value re-

mains unchanged

during filling

Level

time

0

– False echoes in the close range

too big or product echo too

small

– Strong foam or spout genera-

tion

– Max. adjustment not correct

– Eliminate false echoes in the

close range

– Check measurement situation:

Antenna must protrude out of

the socket, installations

– Remove contamination on the

antenna

– Minimize interfering instal-

lations in the close range by

changing the polarization

direction

– Create a new false signal sup-

pression

– Adapt max. adjustment

5. Measured value re-

mains in the bottom

section during filling

Level

time

0

– Echo from the tank bottom

larger than the product echo,

for example, with products with

ε

r

< 2.5 oil-based, solvents

– Check application parameters

Medium, Vessel height and

Floor form, adapt if necessary

6. Measured value re-

mains momentarily

unchanged during fill-

ing and then jumps to

the correct level

Level

time

0

– Turbulence on the product

surface, quick filling

– Check application parameters,

change if necessary, e.g. in

dosing vessel, reactor