4 mounting, 1 general instructions, 2 mounting instructions – VEGA VEGAKON 61 - Relay (DPDT) User Manual

Page 9: 4mounting

4

Mounting

4

.1 General instructions

Make sure that all parts of the instrument exposed to the process, in

particular the sensor element, process seal and process fitting, are

suitable for the existing process conditions. These include above all

the process pressure, process temperature as well as the chemical

properties of the medium.

You can find the specifications in chapter "Technical data" or on the

type label.

Use the recommended cables (see chapter "Connecting to power

supply") and tighten the cable gland.

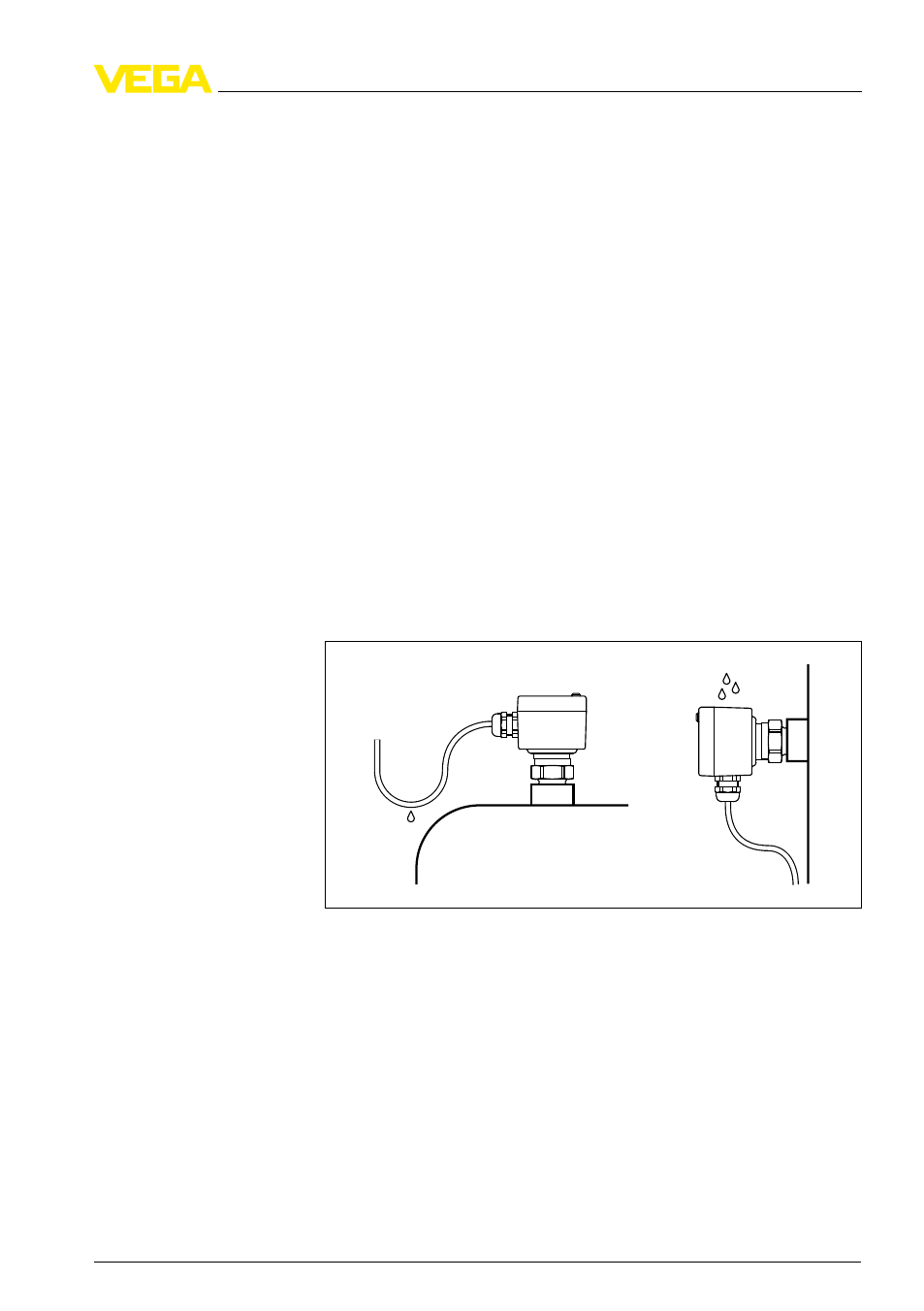

You can give your VEGAKON 61 additional protection against

moisture penetration by leading the connection cable downward in

front of the cable entry. For this reason, the housing can be turned

without any tools by 270°. Rain and condensation water can thus drain

off. This applies mainly to outdoor mounting as well as installation in

areas where high humidity is expected (e.g. through cleaning

processes) or on cooled or heated vessels.

Fig. 3: Measures against moisture penetration

The process fitting must be sealed if there is gauge or low pressure in

the vessel. Before use, check if the seal material is resistant against

the measured product and the process temperature.

The max. permissible pressure is specified in chapter "Technical data"

or on the type label of the sensor.

4

.2 Mounting instructions

Remove the supplied seal from the thread of VEGAKON 61. This seal

is not required when using the welded socket with O-ring in front.

Suitability for the pro-

cess conditions

Moisture

Pressure/Vacuum

Welded socket

VEGAKON

61 • - Relay (DPDT)

9

4 Mounting

32647

-

EN

-100219