2 mounting instructions – VEGA VEGAPULS 65 (≥ 2.0.0 - ≤ 3.8) Profibus PA User Manual

Page 14

1

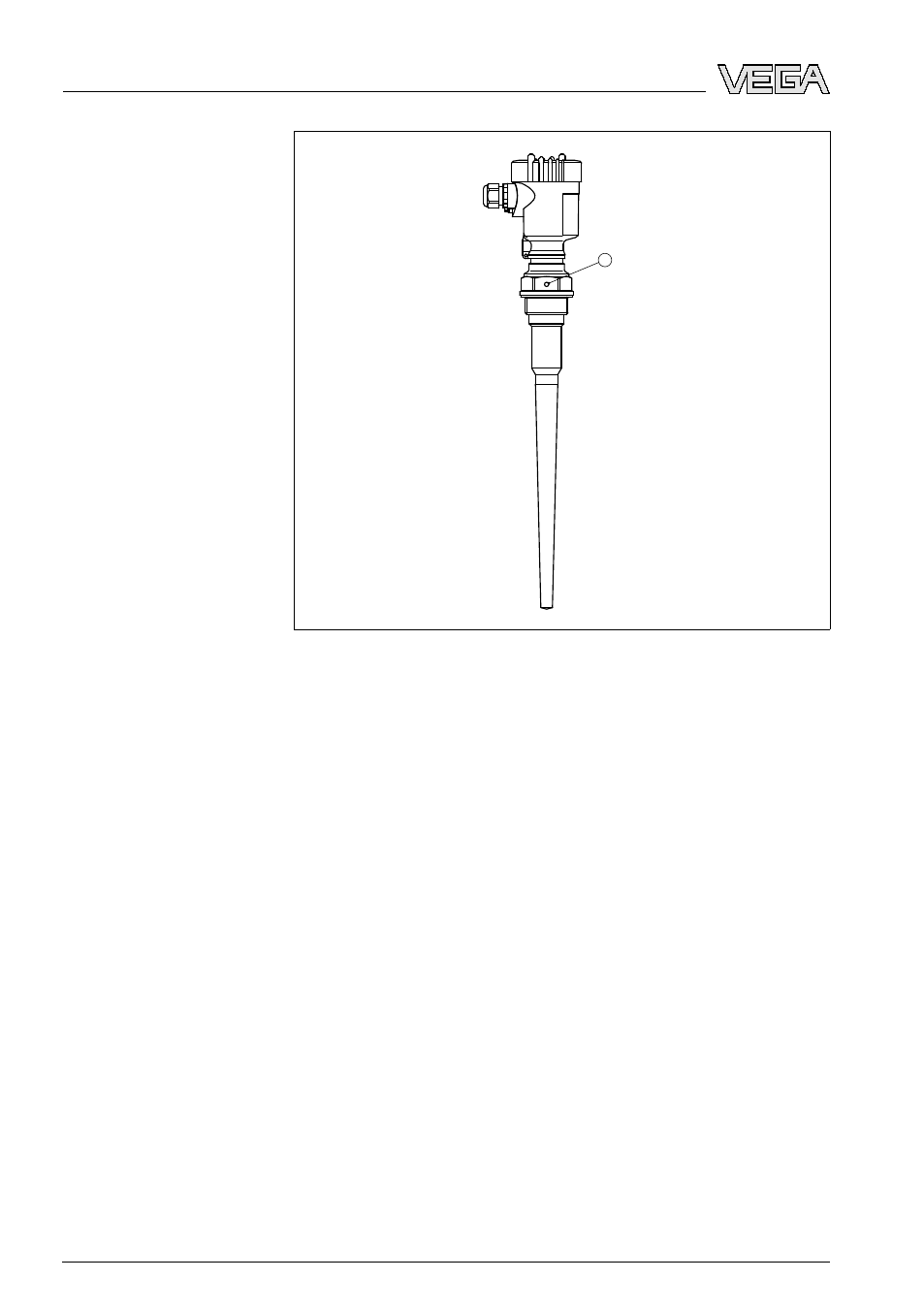

Fig. 4: Position of the polarisation plane with VEGAPULS 65

1

Marking hole

Make sure that all parts of the instrument in contact with the measured

product, especially the sensor element, process seal and process

fitting, are suitable for the existing process conditions such as process

pressure, process temperature as well as the chemical properties of

the medium.

You can find the specifications in chapter "Technical data" in the or on

the type label.

4.2 Mounting instructions

The flange screws of VEGAPULS 65 must be always screwed with the

torque stated in the technical data so that the PTFE washer of the

encapsulated antenna system seals.

You can counteract the material-induced tension loss with PTFE by

doing the following:

1

Make sure the number of flange screws corresponds to the

number of flange holes

2

Use disc springs in addition to the flange screws for fastening the

flange

3

Tighten the screws steadily with the torque specified in the

technical data

Suitability for process

conditions

Mounting of instruments

with PTFE-coated

flanges

14

VEGAPULS

65 • Profibus PA

4 Mounting

28447

-EN

-090305