8 maintenance and fault rectification, 1 maintenance, 2 remove interferences – VEGA VEGAPULS 63 (≥ 2.0.0 - ≤ 3.8) Profibus PA User Manual

Page 43: 8 maintenance and fault rectification

8 Maintenance and fault rectification

8.1 Maintenance

If the instrument is used properly, no special maintenance is required

in normal operation.

8.2 Remove interferences

The operator of the system is responsible for taking suitable measures

to rectify faults.

VEGAPULS

63 offers maximum reliability. Nevertheless, faults can

occur during operation. These may be caused by the following, e.g.:

l

Sensor

l

Process

l

Voltage supply

l

Signal processing

The first measures to be taken are to check the output signals as well

as to evaluate the error messages via the indicating and adjustment

module. The procedure is described below. Further comprehensive

diagnostics can be carried out on a PC with the software PACTware

and the suitable DTM. In many cases, the causes can be determined

and the faults rectified this way.

Should these measures not be successful, please call in urgent cases

the VEGA service hotline under the phone no. +49 1805 858550.

The hotline is available to you 7 days a week round-the-clock. Since

we offer this service world-wide, the support is only available in the

English language. The service is free of charge, only the standard

telephone costs will be charged.

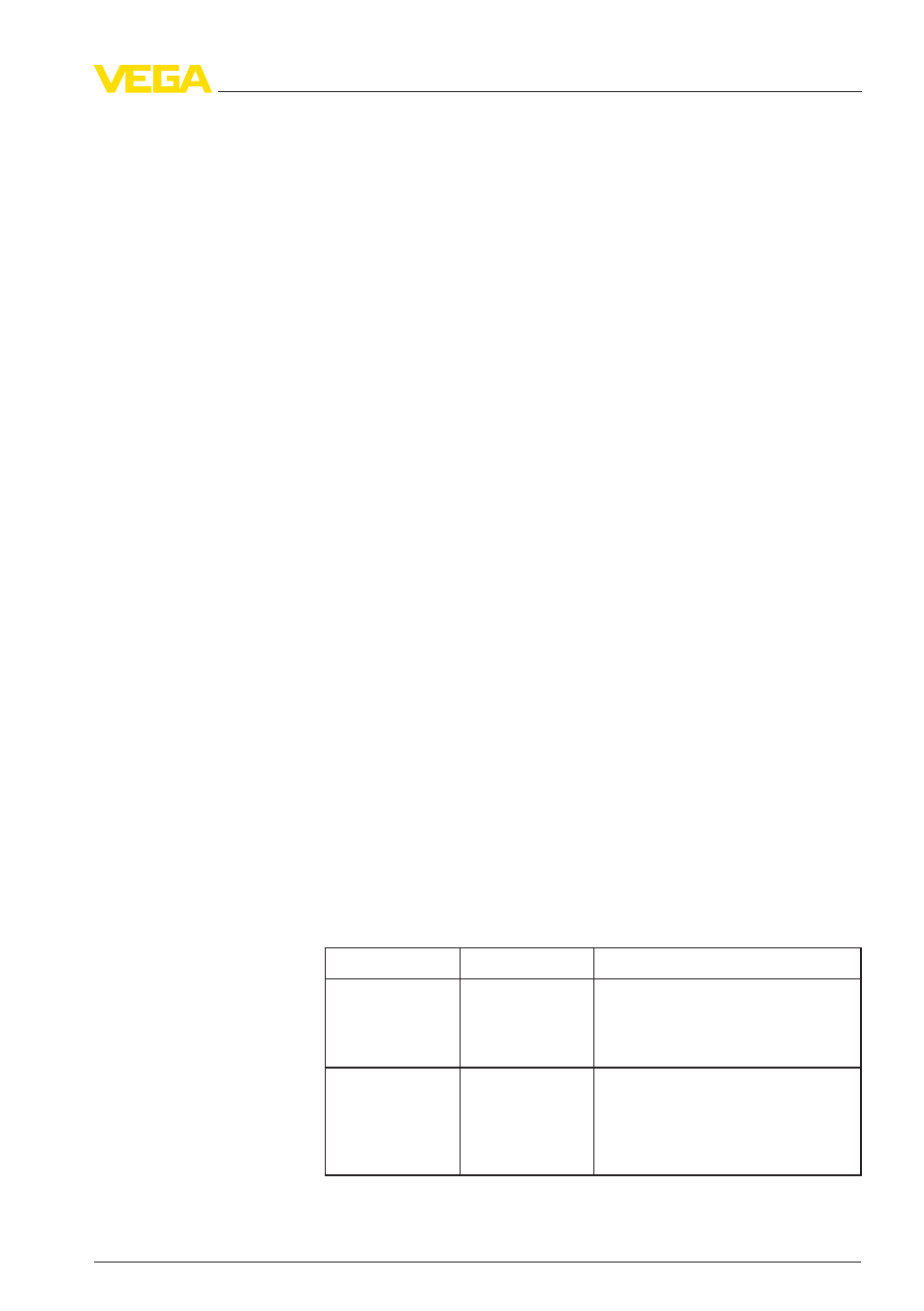

The following table describes possible errors and helps to remove

them:

Error

Cause

Rectification

When an additio-

nal instrument is

connected, the

segment fails.

Max. supply cur-

rent of the seg-

ment coupler

exceeded

Measure the current consumption,

reduce size of segment

Wrong presenta-

tion of the measu-

red value in

Simatic S5

Simatic S5 can-

not interpret the

number format

IEEE of the mea-

sured value

Insert converting component from

Siemens

Reaction when malfunc-

tions occur

Failure reasons

Fault rectification

24 hour service hotline

Checking Profibus PA

VEGAPULS

63 • Profibus PA

43

8 Maintenance and fault rectification

28446

-EN

-120530