VEGA VEGASCAN 693 User Manual

Page 20

20

6 Setup with the integrated display and adjustment unit

VEGASCAN 693 • 15-channel HART signal conditioning instrument

29252-EN-130701

→

Carry out your settings via the respective keys and save with

[OK]. Further information is available in the supplementary

instructions manual "RS232/Ethernet connection" and the online

help of the respective DTM.

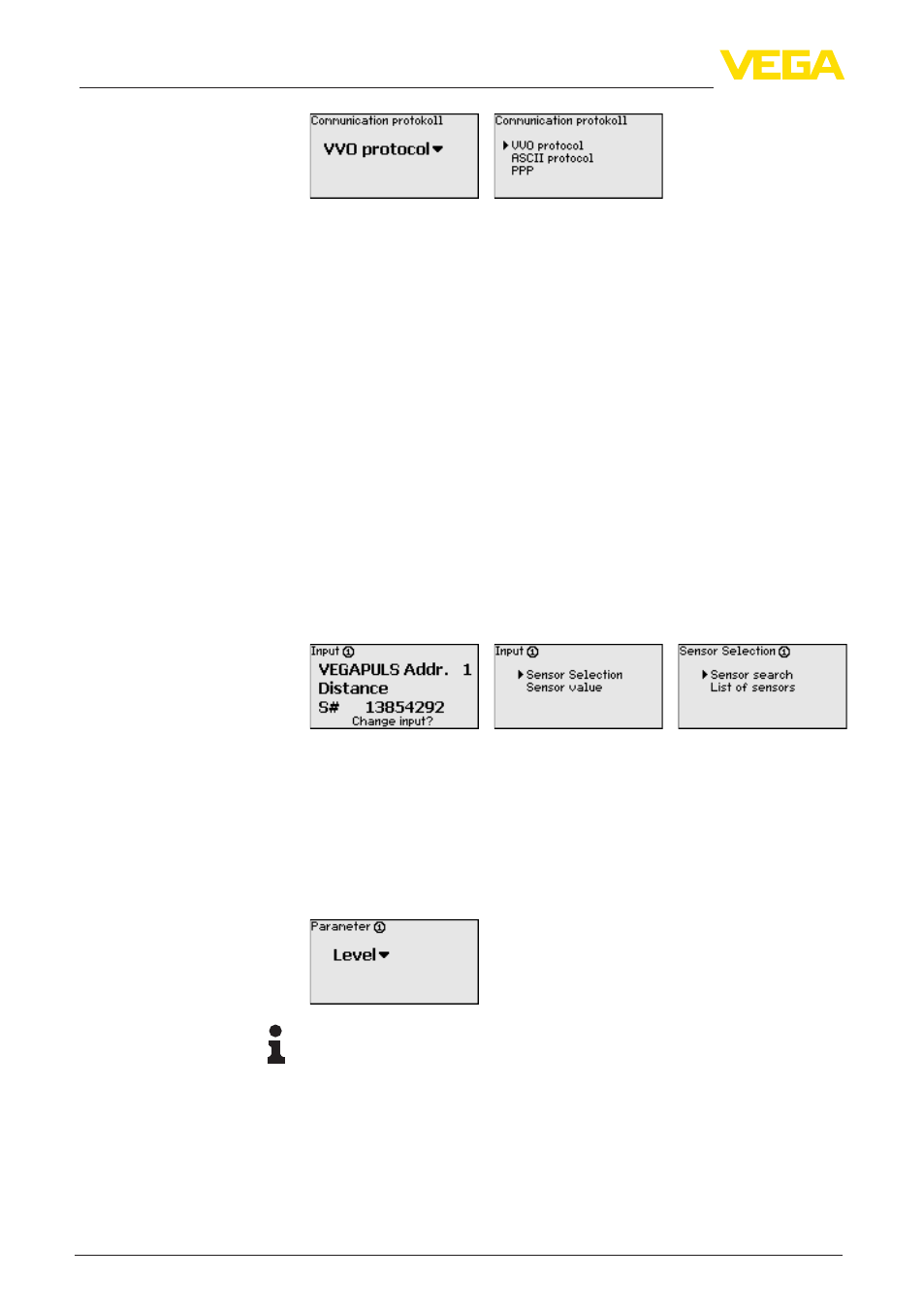

Because VEGASCAN 693 can read the measured values of up to 15

sensors (5 with Ex), the individual sensors must be assigned to the

measurement loops. After the addresses of the HART sensors are as-

signed, a list with the existing sensors can be prepared and displayed.

Now you can assign the requested sensor to each measurement loop.

For transmission, VEGASCAN 693 must be informed which sensor

value should be used for further processing. Depending on the sen-

sor type this can be distance, pressure, interface or temperature. If a

sensor can deliver two measured values, e.g. pressure and tempera-

ture with VEGABAR sensors, a separate measurement loop must

be assigned for each input variable. When HART sensors of other

manufacturers are connected, the options PV (Primary Value) and SV

(Secondary Value) will be available. The parameter to be transmitted

is stated in the operating instructions manual of the respective sensor

manufacturer.

The measured variable defines the applicaton of the measurement

loop, the following settings are available depending on the connected

sensor:

•

Level

•

Process pressure

•

Temperature

•

Universal (for sensors of other manufacturers)

Information:

Keep in mind that some settings must be carried out individually sev-

eral times, because they are specifically required for each measure-

ment loop.

Through the adjustment the input value of the connected sensor is

converted into a percentage value. This conversion step allows any

input value range to be depicted in a relative range (0 % up to 100 %).

Measurement loop - Input

Meas. loop - Parameter

Meas. loop - Adjustment