2 exchange of hygienic form seal on d94 – VEGA D94 Profibus PA User Manual

Page 33

Pressure transmitter D94 (Profibus PA)

33

Notes

6.2 Exchange of hygienic form seal

on D94

On the hygienic connections AA, CA, LA, LB,

RA, RB, TA of pressure transmitter D94, the

ceramic measuring cell is radially, gaplessly

sealed with a form seal. This form seal (mate-

rial EPDM-FDA) can be exchanged by the

user without the need of a fresh adjustment.

The criteria and the time intervals for such an

exchange of the seal are generally defined

by the process and hygienic requirements.

Important:

Use only original replacement seals from

VEGA!

Please note the following exchange proce-

dure.

Removal procedure:

•

Pressure transmitter should be unpres-

surized (switch off process pressure or

empty vessel).

•

Loosen the hexagon pressure screw (4)

(width across flats, 46 mm) by turning to

the left.

Note!

The process connection (6) (e.g. compres-

sion nut) must not be loosened!

•

Turn the adapter (3) below the pressure

transmitter housing with a screwdriver

(with across flats, 36 mm) briefly to the

left (to loosen the seal).

•

Pull the complete pressure transmitter on

the housing (1) out of the process con-

nection by carefully turning to the left.

•

Slightly lift the form seal (5) and loosen

from the ceramic measuring cell.

•

If the form seal (5) does not completely

encircle the measuring cell, it must be

carefully removed from the process con-

nection.

Installation procedure:

•

Put the new form seal (5) over the meas-

uring cell (the conical end must point to

the process connection!).

•

Carefully insert pressure transmitter into

the process connection by turning clock-

wise.

•

Tighten hexagon pressure screw (4)

(width across flats, 46 mm) (45 Nm).

•

Turn the housing (1) of the pressure

transmitter into the original position.

The exchange of the form seal is now fin-

ished; the removed seal must be properly

disposed of.

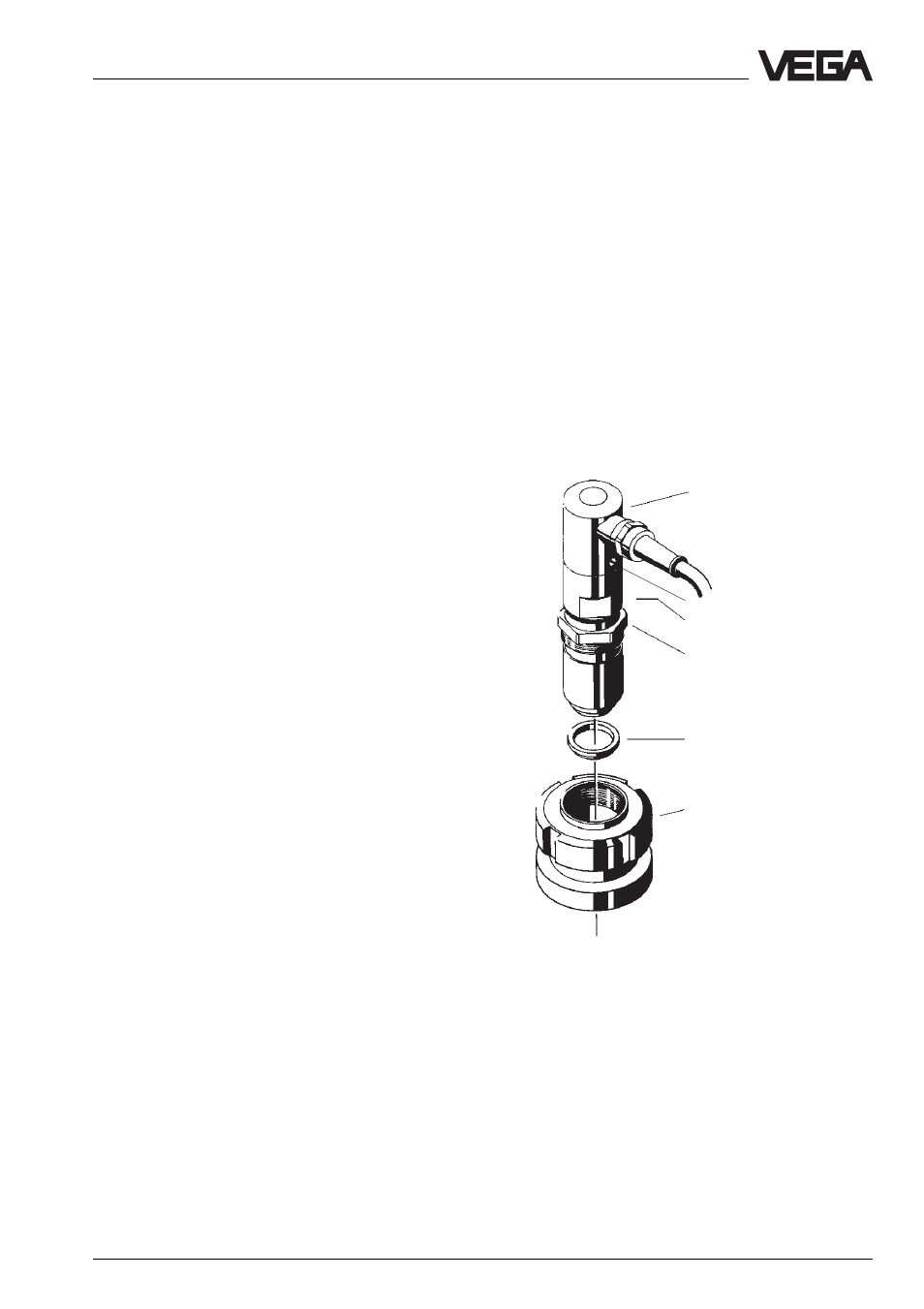

1 Pressure transmitter

2 Headless screw (avoids overwinding and must not be

removed)

3 Adapter

4 Hexagon screw

5 Form seal

6 Process connection

1

2

3

4

5

6