Operation, Maintenance and service – Bosch GPO 14 CE Professional User Manual

Page 16

English | 17

Bosch Power Tools

1 619 929 J63 | (9.9.11)

Observe the relevant regulations in your country for the

materials to be worked.

f

Prevent dust accumulation at the workplace. Dusts can

easily ignite.

Operation

Starting Operation

f

Observe correct mains voltage! The voltage of the pow-

er source must agree with the voltage specified on the

nameplate of the machine. Power tools marked with

230 V can also be operated with 220 V.

Switching On and Off

To start the power tool, press the On/Off switch 5 forward

and then down.

To lock-on the pressed On/Off switch 5, push the On/Off

switch 5 further forward.

To switch off the power tool, release the On/Off switch 5, or

when it is locked, briefly press the On/Off switch 5 and then

release it.

f

Check grinding tools before using. The grinding tool

must be mounted properly and be able to move freely.

Carry out a test run for at least one minute with no load.

Do not use damaged, out-of-centre or vibrating grind-

ing tools. Damaged grinding tools can burst and cause in-

juries.

Speed preselection

The required speed can be preselected with the thumbwheel

4 (also while running).

The required speed depends on the material and the working

conditions and can be determined through practical testing.

Constant Electronic Control

Constant electronic control holds the speed constant at no-

load and under load, and ensures uniform working perform-

ance.

Working Advice

f

Clamp the workpiece if it does not remain stationary

due to its own weight.

f

Do not strain the machine so heavily that it comes to a

standstill.

f

After heavily straining the power tool, continue to run

it at no-load for several minutes to cool down the acces-

sory.

For sanding applications on soft materials, e. g., gypsum or

paint, it is recommended to use the rubber sanding plate 18

with sanding sheet 19.

Cup brushes 21 and wheel brushes are suitable for rust re-

moval.

Polishing

For the polishing of weathered paint or buffing out scratches

(e.g., acrylic glass), the machine can be equipped with appro-

priate polishing accessories such as lamb’s wool bonnet, pol-

ishing felt or sponge (accessories).

Select a low speed for polishing (stage 1 – 2) in order to avoid

excessive heating of the surface.

Apply the polish onto a somewhat smaller surface than you in-

tend to polish. Work the polishing agent in with a suitable pol-

ishing tool applying it crosswise or with circular motion and

moderate pressure.

Do not allow the polishing agent to dry out on the surface, oth-

erwise the surface can become damaged. Do not subject the

surface to be polished to direct sunlight.

Clean the polishing accessories regularly to ensure good pol-

ishing results. Wash out polishing accessories with a mild de-

tergent and warm water; do not use paint thinner.

Maintenance and Service

Maintenance and Cleaning

f

Before any work on the machine itself, pull the mains

plug.

f

For safe and proper working, always keep the machine

and ventilation slots clean.

f

In extreme conditions, always use dust extraction as

far as possible. Blow out ventilation slots frequently

and install a residual current device (RCD). When work-

ing metals, conductive dust can settle in the interior of the

power tool. The total insulation of the power tool can be im-

paired.

Please store and handle the accessory(-ies) carefully.

If the machine should fail despite the care taken in manufac-

turing and testing procedures, repair should be carried out by

an after-sales service centre for Bosch power tools.

In all correspondence and spare parts order, please always in-

clude the 10-digit article number given on the type plate of

the machine.

After-sales Service and Customer Assistance

Our after-sales service responds to your questions concern-

ing maintenance and repair of your product as well as spare

parts. Exploded views and information on spare parts can al-

so be found under:

www.bosch-pt.com

Our customer service representatives can answer your ques-

tions concerning possible applications and adjustment of

products and accessories.

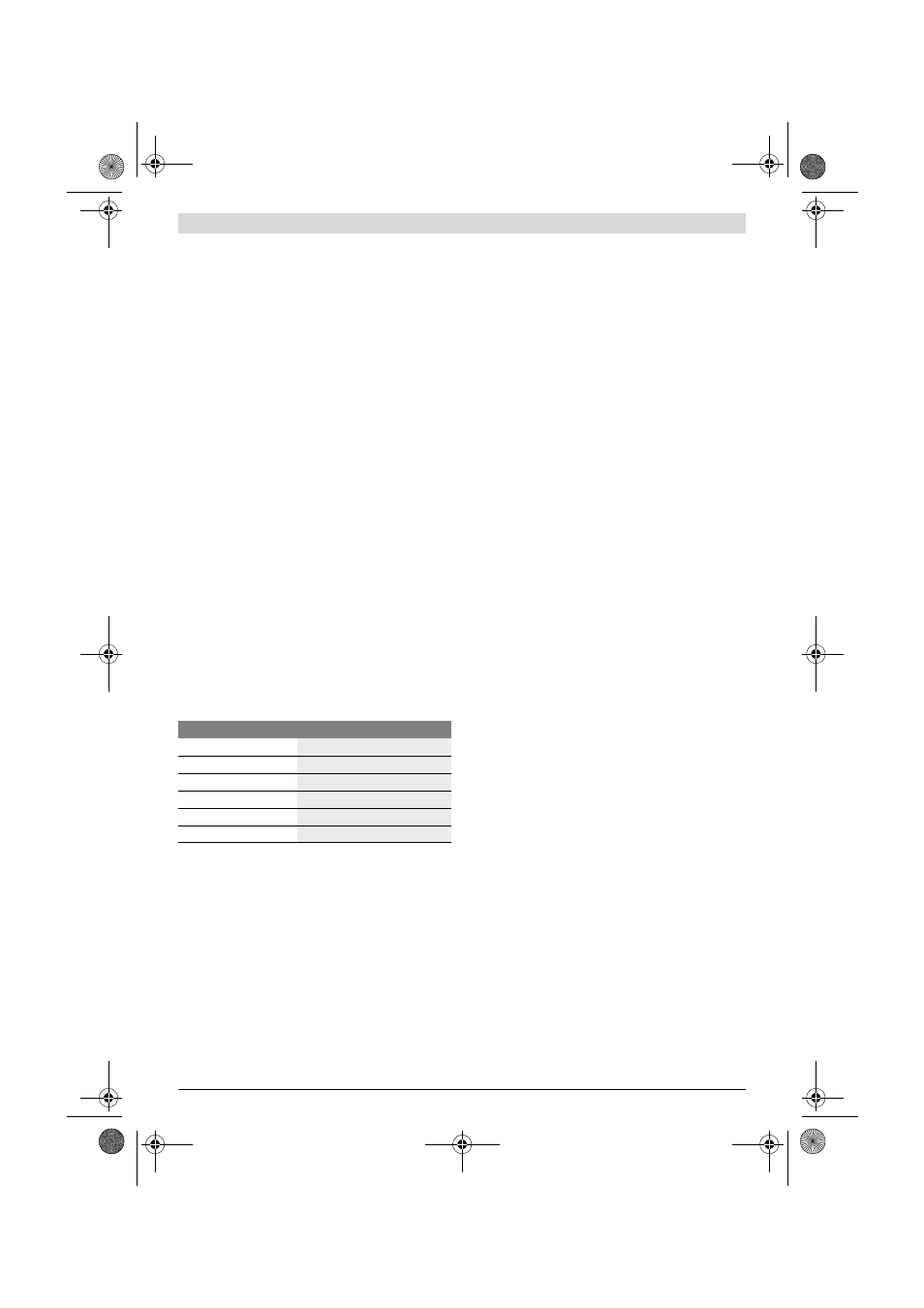

Thumbwheel Position

No-load speed (min

-1

)

1

750

2

1200

3

1600

4

2000

5

2400

6

3000

OBJ_BUCH-1284-002.book Page 17 Friday, September 9, 2011 8:58 AM