Bosch PFS 55 User Manual

Page 19

English | 19

Bosch Power Tools

1 609 929 Y12 | (22.8.11)

Changing the Air Filter (see figure L)

Note: Never operate the powr tool without the air filter. With-

out the air filter, dirt/contamination can be drawn in and can

influence the operation of the power tool.

The air filter must be replaced when soiled.

– Loosen screw 7.

– Remove the air filter cover 3.

– Replace the air filter.

– Reattach the air filter cover and screw in the screw again.

Material Disposal

Diluting agent and remainders of spray material must be dis-

posed of in an environmentally-friendly manner. Observe the

manufacturer’s disposal information and the local regulations

for disposal of hazardous waste.

Chemicals harmful to the environment may not be disposed

of into soil, groundwater or bodies of water. Never pour

chemicals harmful to the environment into the sewerage sys-

tem!

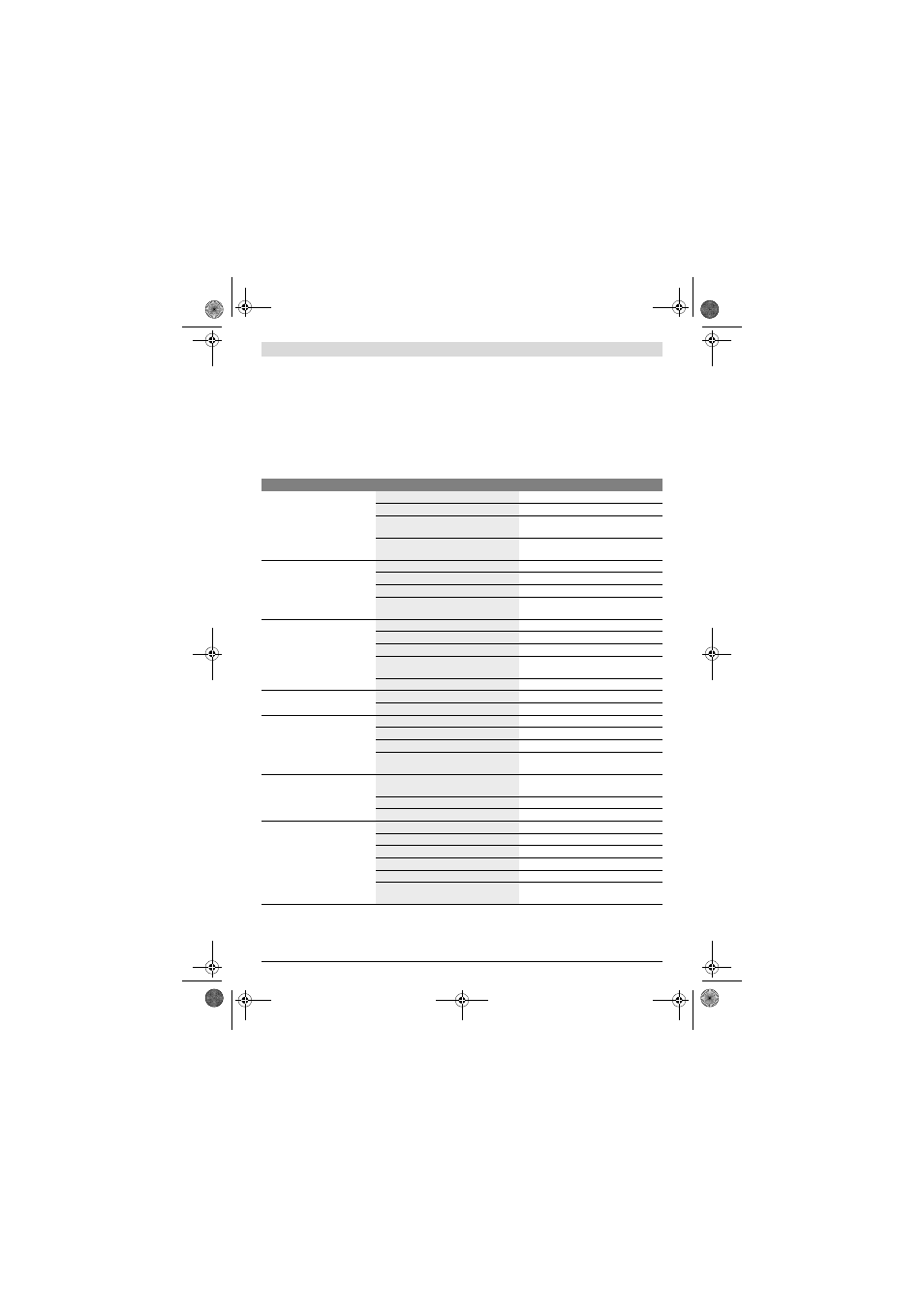

Correction of Malfunctions

Maintenance

If the machine should fail despite the care taken in manufac-

turing and testing procedures, repair should be carried out by

an after-sales service centre for Bosch power tools.

In all correspondence and spare parts order, please always in-

clude the 10-digit article number given on the type plate of

the machine.

Problem

Cause

Corrective Measure

Spray material does not cover

properly

Spraying capacity too low

Turn thumbwheel 15 in direction +

Clearance to target area too large

Reduce spray distance

Not enough spray material on target area,

too few spray paths sprayed over target area

Apply more spray paths over target area

Spray material too viscous

Thin down the spray material by 10% again

and carry out a test-spray run

Spray material runs off after

coating

Too much spray material applied

Turn thumbwheel 15 in direction –

Clearance to target area too close

Increase spray distance

Viscosity of spray material too low

Add original spray material

Spray material applied too often over same

spot

Remove spray material; reduce number of

spray paths over same spot

Atomisation too course

Spraying capacity too high

Turn thumbwheel 15 in direction –

Nozzle 20 soiled

Clean nozzle

Too little pressure build-up in container 11 Screw container firmly against spray gun

Spray material too viscous

Thin down the spray material by 10% again

and carry out a test-spray run

Air filter heavily soiled

Changing the Air Filter

Excessive paint mist

Too much spray material applied

Turn thumbwheel 15 in direction –

Clearance to spray surface too large

Reduce spray distance

Spray jet pulsates

Not enough spray material in container

Refill spray material

Venting hole on suction tube 10 clogged

Clean suction tube and hole

Air filter heavily soiled

Changing the Air Filter

Spray material too viscous

Thin down the spray material by 10% again

and carry out a test-spray run

Spray material drips from the

nozzle

Build-up of spray material on nozzle 20 and

air cap 13

Clean nozzle and air cap

Nozzle 20 worn

Replace nozzle

Nozzle 20 loose

Tighten union nut 14

No spray material emerges from

the nozzle

Nozzle 20 clogged

Clean nozzle

Suction tube 10 clogged

Clean suction tube

Venting hole on suction tube 10 clogged

Clean suction tube and hole

Suction tube 10 loose

Insert suction tube properly

No pressure build-up in container 11

Screw container firmly against spray gun

Spray material too viscous

Thin down the spray material by 10% again

and carry out a test-spray run

OBJ_BUCH-670-002.book Page 19 Monday, August 22, 2011 1:10 PM