Maintenance and service – Bosch GDR 10,8-LI Professional User Manual

Page 15

English | 15

Bosch Power Tools

1 609 92A 0BV | (18.6.13)

The impact duration is to be determined for each required

tightening torque. The actually achieved tightening torque is

always to be checked with a torque wrench.

Screw Applications with Hard, Spring-loaded or Soft Seat

When in a test, the achieved torques in an impact series are

measured and transferred into a diagram, resulting in the

curve of a torque characteristic. The height of the curve corre-

sponds with the maximum reachable torque, and the steep-

ness indicates the duration in which this is achieved.

A torque gradient depends on the following factors:

– Strength properties of the screws/nuts

– Type of backing (washer, disc spring, seal)

– Strength properties of the material being screwed/bolted

together

– Lubrication conditions at the screw/bolt connection

The following application cases result accordingly:

– A hard seat is given for metal-to-metal screw applications

with the use of washers. After a relatively short impact du-

ration, the maximum torque is reached (steep characteris-

tic curve). Unnecessary long impact duration only causes

damage to the machine.

– A spring-loaded seat is given for metal-to-metal screw ap-

plications, however with the use of spring washers, disc

springs, studs or screws/nuts with conical seat as well as

when using extensions.

– A soft seat is given for screw applications, e. g., metal on

wood or when using lead washers or fibre washers as back-

ing.

For a spring-loaded seat as well as for a soft seat, the maxi-

mum tightening torque is lower than for a hard seat. Also, a

clearly longer impact duration is required.

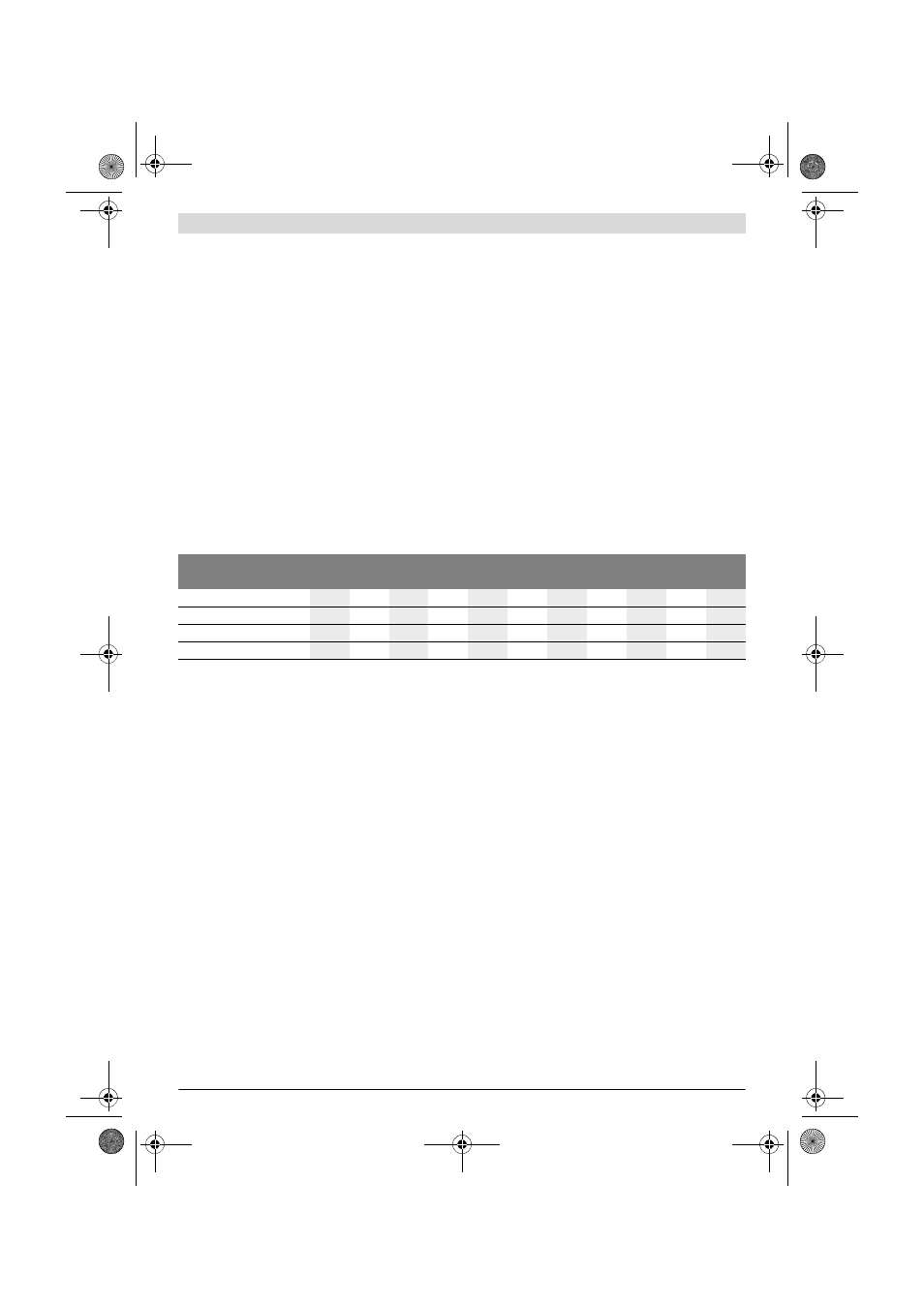

Reference Values for Maximum Screw/Bolt Tightening Torques

Calculated from the tensional cross-section; utilization of the yield point 90 % (with friction coefficient μ

total

= 0.12). As a control

measure, always check the tightening torque with a torque wrench.

Tips

Before screwing larger, longer screws into hard materials, it is

advisable to predrill a pilot hole with the core diameter of the

thread to approx.

2

/

3

of the screw length.

Maintenance and Service

Maintenance and Cleaning

Before any work on the machine itself (e. g. mainte-

nance, tool change, etc.) as well as during transport

and storage, remove the battery from the power tool.

There is danger of injury when unintentionally actuating

the On/Off switch.

For safe and proper working, always keep the machine

and ventilation slots clean.

When the battery is no longer operative, please refer to an au-

thorised after-sales service agent for Bosch power tools.

After-sales Service and Application Service

Our after-sales service responds to your questions concern-

ing maintenance and repair of your product as well as spare

parts. Exploded views and information on spare parts can al-

so be found under:

www.bosch-pt.com

Bosch’s application service team will gladly answer questions

concerning our products and their accessories.

In all correspondence and spare parts order, please always in-

clude the 10-digit article number given on the type plate of

the machine.

Great Britain

Robert Bosch Ltd. (B.S.C.)

P.O. Box 98

Broadwater Park

North Orbital Road

Denham

Uxbridge

UB 9 5HJ

Tel. Service: (0844) 7360109

Fax: (0844) 7360146

E-Mail: [email protected]

Ireland

Origo Ltd.

Unit 23 Magna Drive

Magna Business Park

City West

Dublin 24

Tel. Service: (01) 4666700

Fax: (01) 4666888

Property Classes accord-

ing to DIN 267

Standard Screws/Bolts

High-strength Bolts

3.6

4.6

5.6

4.8

6.6

5.8

6.8

6.9

8.8

10.9

12.9

M 6

2.71

3.61

4.52

4.8

5.42

6.02

7.22

8.13

9.7

13.6

16.2

M 8

6.57

8.7

11

11.6

13.1

14.6

17.5

19.7

23

33

39

M 10

13

17.5

22

23

26

29

35

39

47

65

78

M 12

22.6

30

37.6

40

45

50

60

67

80

113

135

OBJ_BUCH-1066-004.book Page 15 Tuesday, June 18, 2013 10:16 AM