English, Pre-testing checks, Fuel pressure testing procedures – Actron Professional Fuel Pressure Tester Kit CP7838 User Manual

Page 3

Pressure Line: A pressurized fuel line that

carries fuel from the fuel tank to the fuel injectors.

Fuel Filter: A filter that is located in-line with the

pressure line. Its function is to prevent foreign

particles from reaching the fuel injectors. A

clogged or restricted fuel filter can also cause low

fuel pressure readings. This is the only fuel

system component that requires periodic

replacement. Refer to vehicle owners manual for

replacement interval.

Fuel Rail Test Port: A schrader valve located on

the fuel rail that allows easy connection of a fuel

pressure gauge to measure fuel pressure. Do not

confuse this valve with the schrader valves that are

used for recharging air conditioning systems.

Fuel Pressure Regulator: The fuel pressure

regulator is connected across the pressure line

and return line. It contains a spring loaded valve

assembly that opens to allow fuel to move into the

return line, when the pressure line fuel pressure is

English

exceeded. It is used to keep a constant fuel

pressure drop across the fuel injectors. Some fuel

pressure regulators have a vacuum port so fuel

pressure can be adjusted based on engine load.

These are commonly called vacuum actuated

(compensated) fuel pressure regulators. A leaking

fuel pressure regulator can cause low fuel

pressure readings and hard starting problems.

Fuel Rail: The fuel rail assembly is bolted to the

intake manifold. Its purpose is to hold the fuel

injectors in place and to deliver pressurized fuel to

the fuel injectors.

Fuel Injectors: A precision valve that is controlled

by a solenoid. Fuel injection is controlled by the

amount of fuel pressure, and the size and duration

of the valve opening. Fuel injectors contain a filter

used to prevent very small particles from clogging

the valve. Leaking fuel injectors will cause fuel

pressure to slowly decrease when the ignition key

is on and engine is off.

Pre-Testing Checks

1. Read Safety Precautions.

2. Do a thorough visual and hands-on inspection

of the engine and fuel system. Look for loose or

cracked electrical wiring, battery cables,

ignition wires, and fuel or vacuum lines.

3. Verify that the battery is fully charged and fuel

tank has an adequate supply of fuel.

4. Verify that the inertia switch on certain Ford/

Lincoln/Mercury vehicles has not been tripped.

(The inertia switch is usually located in the

trunk.)

5. Verify that all fuel system fuses are good.

6. Verify fuel vapor recovery system and gas cap

are in good condition.

7. Verify that manifold vacuum is within

manufacturers specification which is typically 18-

20 inches at idle.

8. Look for fuel leaks and wipe up any spilled fuel

immediately.

9. If engine will not start, check ignition system for

spark. If no ignition spark is present, refer to

vehicle service manual for No Start Diagnostics.

10.Inspect wire harnesses and electrical

connectors for damaged or corroded parts.

11. Check other electrical systems including

ignition and car computer system.

Fuel Pressure Testing Procedures

This test procedure explains how to make

fuel pressure measurements on vehicles while

ignition key is on and while engine is at idle. The

procedure also explains the safest way to connect

and disconnect fuel pressure tester kit from

vehicles. If fuel pressure readings measured in this

test procedure are not within vehicles

manufacturers specification, then use vehicle

service manual along with fuel pressure tester kit

to service problem. This test procedure does not

contain any vehicle specific diagnostics

.

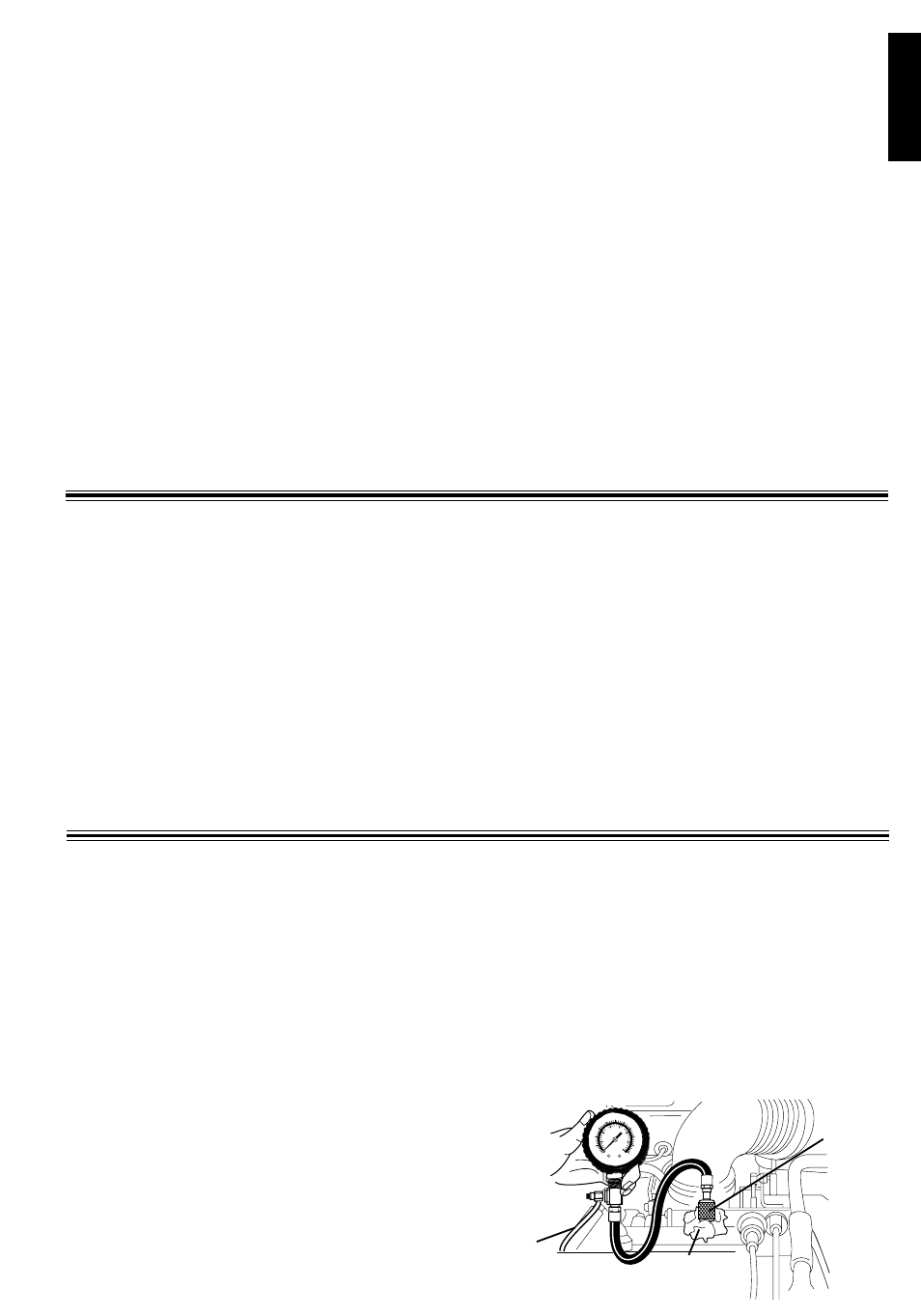

1. Read all SAFETY PRECAUTIONS and PRE-

TESTING CHECKS.

2. Apply a lightweight household oil to rubber O

rings on test adapters.

3. Turn Ignition Key OFF.

4. Install Gauge.

For GM/Chrysler vehicles with test port...

Note: A right-angle large schrader adapter, part

number 0180-1299 is available for close-

clearance connections.

Remove Test Cap.

Screw GM/Chrysler test port adapter to fuel

rail test port until finger tight.

Note: Always wrap a shop rag around fuel rail

test port when attaching test port adapters.

This is a precaution in case a small amount of

fuel leaks out while attaching adapters.

2 0

4 0

6 0

8 0

10 0

10 0

2 0 0

300

500

400

6 0 0

7 0 0

kPa

psi

1 0

3 0

5 0

7 0

9 0

END OF BLEED OFF HOSE

MUST BE PLACED IN AN

APPROVED FUEL CONTAINER

Shop Rag

Test Port

Adapter