Ignition system wires, Fig. 26 – Actron AutoTroubleShooter CP7677 User Manual

Page 21

21

Ignition System Wires

This test measures the resistance

of spark plug and coil tower wires

while they are being flexed. This

test can be used for distributorless

ignition systems (DIS) provided the

system does not mount the ignition

coil directly on the spark plug.

Test Procedure:

1. Remove ignition system wires

one at a time from engine.

• Always grasp ignition system

wires on the boot when re-

moving.

• Twist the boots about a half turn

while pulling gently to remove them.

• Refer to vehicle service manual for

ignition wire removal procedure.

• Inspect ignition wires for cracks,

chaffed insulation, and corroded

ends.

NOTE: Some Chrysler products use

a “positive-locking” terminal electrode

spark plug wire. These wires can

only be removed from inside the dis-

tributor cap. Damage may result if

other means of removal are at-

tempted. Refer to vehicle service

manual for procedure.

NOTE: Some spark plug wires have

sheet metal jackets with the follow-

ing symbol:

. This type of plug

wire contains an “air gap” resistor

and can only be checked with an

oscilloscope.

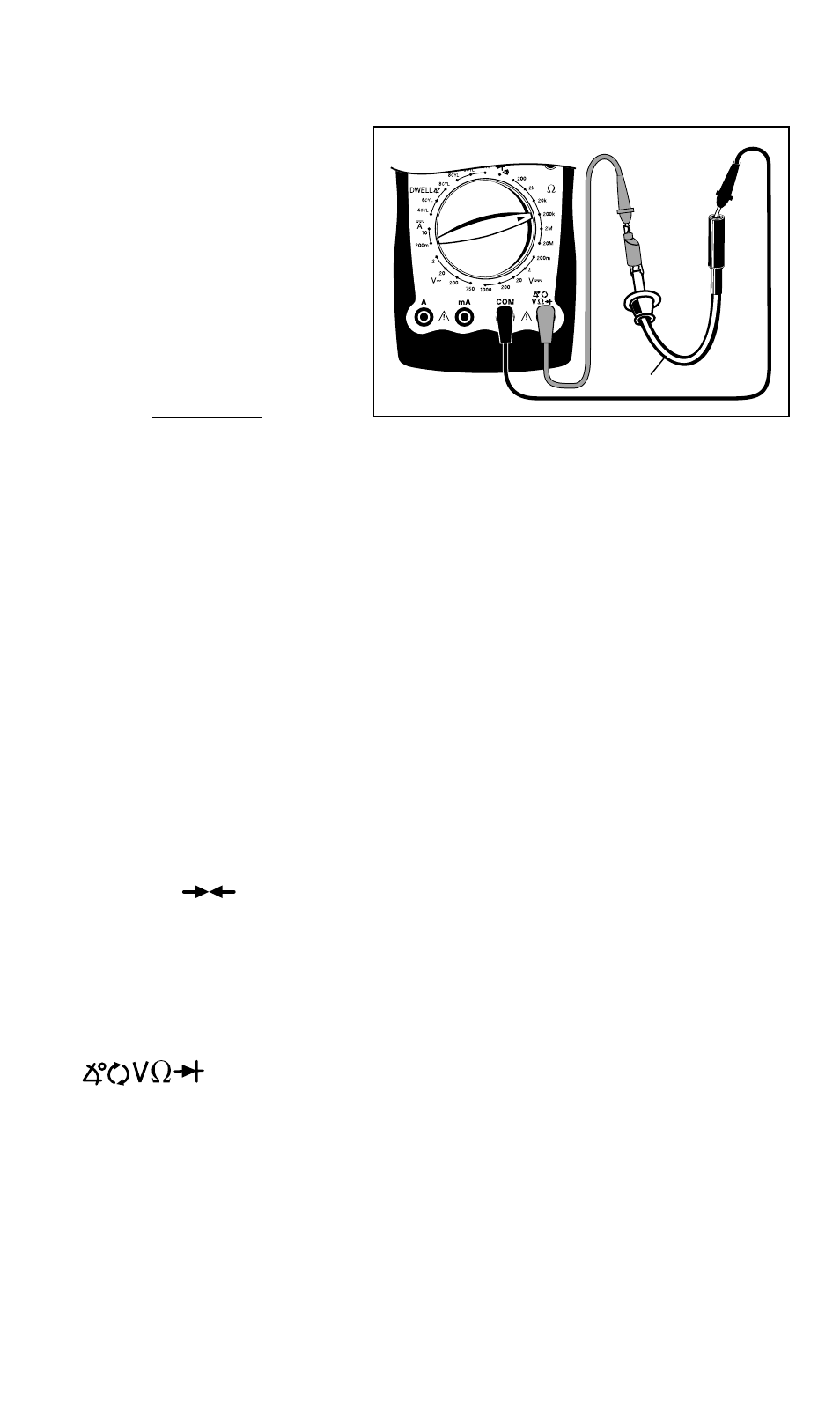

2. Insert BLACK test lead into COM

test lead jack (see Fig. 26).

3. I n s e r t R E D t e s t l e a d i n t o

test lead jack.

4. Connect RED test lead to one end

of ignition wire and BLACK test

lead to other end.

5. Turn multimeter rotary switch to

200K

Ω

range.

6. View reading on display while flex-

ing ignition wire and boot in sev-

eral places.

• Typical resistance range is 3K

Ω

to

50K

Ω

or approximately 10K

Ω

per

foot of wire.

• Refer to vehicle service manual

for your vehicles resistance range.

• As you flex ignition wire, the dis-

play should remain steady.

7. Test Results

Good Ignition Wire: Display reading

is within manufacturers specifica-

tion and remains steady while wire

is flexed.

Bad Ignition Wire: Display reading

erratically changes as ignition wire

is flexed or display reading is not

within manufacturers specification.

Fig. 26

Black

Spark Plug Wire

Red