6 installation location, 5 technical data, 7 preparing for unit instal- lation – STIEBEL ELTRON DHF 12 - 24 C 01.10.2006 - 31.03.2007 User Manual

Page 14

14

2.6 Installation location

The DHF ... C compact control is to

be installed vertically in accordance

with

A

(over-sink or under-sink) in a

closed, frost-free room, as near as possible

to the tap point (a dismantled unit is to be

stored in frost-free conditions, since resi-

dual water always remains in the unit).

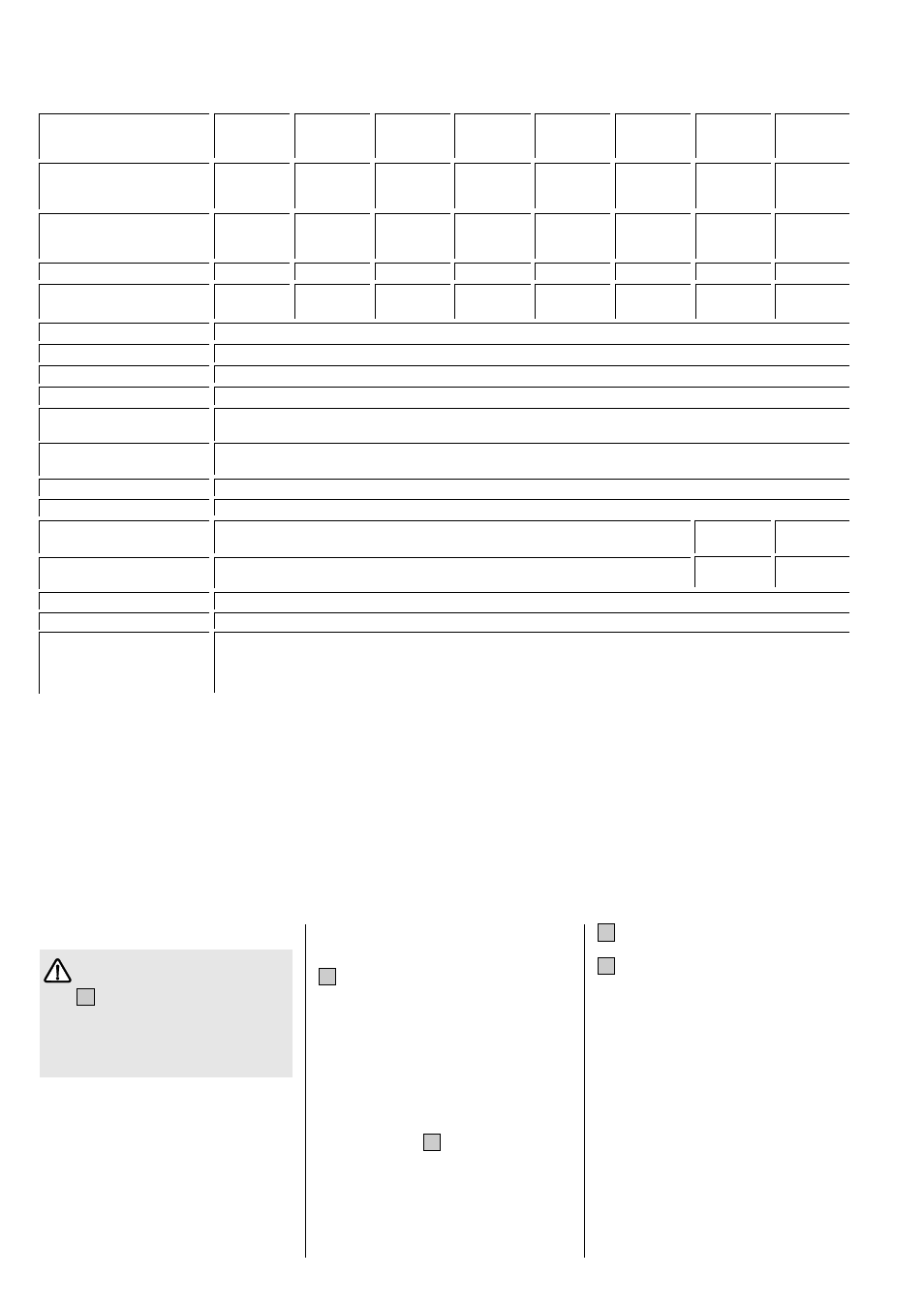

2.5 Technical data

(the data on the unit rating plate are applicable)

2.7 Preparing for unit instal-

lation

B

Turn locking cap (3) to the left and with-

draw.

Unscrew cover securing screw and re-

move device cover.

– Detach mounting bracket (19) from the

unit.

– Thoroughly flush through the cold water

supply pipe.

– In the case of a replacement installation,

the available cold water 3-way three-way

isolating valve (

D

, 6) can if necessary be

used.

– With the help of the template (separate

this from the operating and installation

instructions), determine the position of

the cable entry (concealed connection)

and the mounting bracket (19).

G

Cut the electrical connection cable to

length and strip.

C

Secure the mounting bracket.

When replacing DHF/DHA old models

(height 370 mm), the available drilled

securing holes (20) can be used.

– Secure the unit to mounting bracket with

the screwed sleeve (14). Using the nut

on the threaded bolt (21), unevennesses

in the wall, caused for example by mis-

aligned tiles, can be compensated for

(maximum 12 mm).

Table 3

* Pressure drop values also apply to the minimum flow pressure in accordance with DIN 44851 / Flow rate for heating from 10 °C to 55 °C

(

∆ ϑ

45 K). A pressure drop of 0.1 MPa (1 bar) is recommended for pipe network dimensioning, in line with DIN 1988 Part 3, Table 4.

Electrical connection

3/PE ~ 400 V

1/N/PE ~

3/PE ~ 230 V

220/230 V

Max. system-impedance Z max

to DIN EN 61000-3-11

Ω

0.14

Protection mode to

DIN EN 60529

IP 24

Type

DHF 13 C

DHF 13 C-A DHF 15 C

DHF 18 C

DHF 21 C

DHF 24 C

DHF 12 C1 DHF 13 C3

compact

compact

compact

compact

compact

compact

compact

compact

control

control

control

control

control

control

control

control

Heat output

V

400

400

400

400

400

400

220

230

230

Partial power Stage

z

kW

6.6

6.6

7.5

9

10.5

12

8

8.8

6.6

Rated power Stage zz kW 13.2

13.2

15

18

21

24

12

13.2 13.2

Min. flow rate to activate unit

Stage z l/min

2.5

3.0

3.0

3.9

4.4

4.9

2.5

2.5

Stage zz l/min

3.7

4.5

4.5

5.9

6.4

7.6

3.7

3.7

Flow rate limiter

l/min

6.5

6.5

6.5

7.0

7.5

8.0

6.5

6.5

Pressure loss *

MPa 0.05

0.055

0.055

0.06

0.06

0.07

0.05

0.05

Flow rate

l/min

3.7

4.5

4.5

5.9

6.4

7.6

3.7

3.7

Nominal water volume

l

0.6

Type of construction

Closed

Rated overpressure

MPa

1 (10 bar)

Weight

kg

4.0

Protection class to

DIN EN 60335

1

Test mark

See unit rating plate

Water connection

G ½ (external thread)

Heating element

Copper tubular heating element

Cold water inlet

≤

20 °C

Use in waters

Total alkaline earths

≤

2.5 mol/m³

Overall hardness (earlier unit)

≤

14 °d

Hardness range (earlier unit)

Inclusive of 2 (medium hard)