York F3EH090 User Manual

Page 8

035-09651-001-A-0304

8

Unitary Products Group

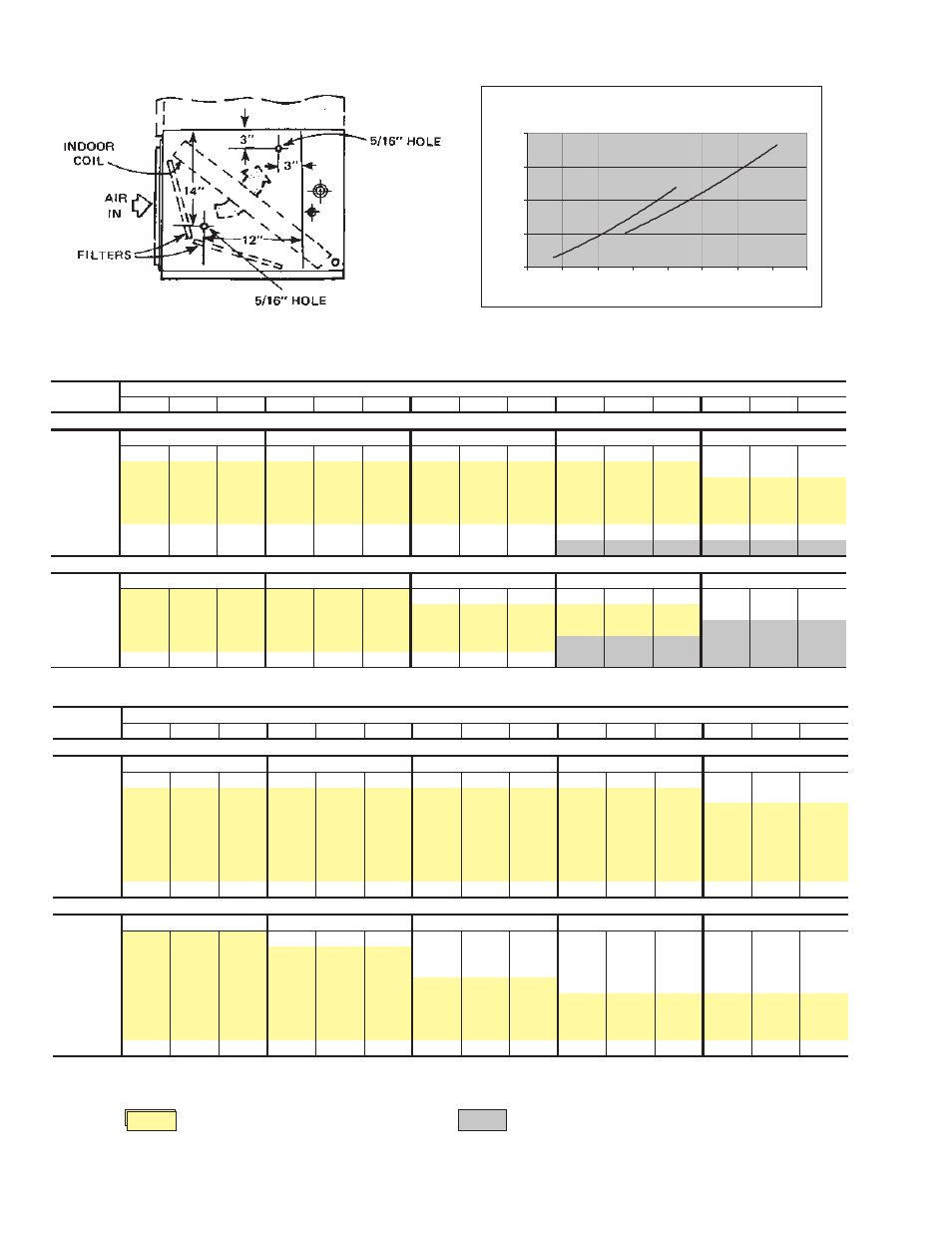

FIG. 9 - HOLE LOCATIONS FOR PRESSURE

DROP READINGS

PRESSURE DROP

ACROSS DRY INDOOR COIL

0.1

0.2

0.3

0.4

0.5

2000

2400

2800

3200

3600

4000

4400

4800

5200

SUPPLY AIR CFM

PR

ESSU

R

E

D

R

OP

(IWG)

FEH090

FEH120

FIG. 10 - PRESSURE DROP ACROSS A DRY

INDOOR COIL VS. SUPPLY AIR CFM

RPM

CFM

ESP

2

BHP

KW

ESP

2

BHP

KW

ESP

2

BHP

KW

ESP

2

BHP

KW

ESP

2

BHP

KW

F3EH090

(60 Hz)

2400

2700

3000

3300

3600

600

0.30

0.62

0.79

0.21

0.70

0.76

0.09

0.78

0.89

-

-

-

-

-

-

655

0.43

0.70

0.86

0.39

0.78

0.83

0.26

0.87

0.97

0.11

0.96

1.07

-

-

-

700

0.52

0.77

0.93

0.48

0.85

0.90

0.40

0.95

1.06

0.28

1.06

1.16

0.14

1.17

1.26

800

0.82

0.97

1.10

0.81

1.06

1.07

0.74

1.18

1.27

0.63

1.30

1.38

0.51

1.42

1.49

880

1.10

1.11

1.24

1.09

1.24

1.21

1.02

1.37

1.45

0.91

1.50

1.55

0.78

1.64

1.70

900

1.15

1.15

1.27

1.14

1.28

1.24

1.07

1.42

1.49

0.97

1.55

1.60

0.87

1.70

1.74

1000

1.49

1.35

1.46

1.47

1.48

1.43

1.42

1.63

1.65

1.35

1.81

1.82

1.27

2.02

2.02

F4EH120

(60 Hz)

3200

3600

4000

4400

4800

700

0.30

1.01

1.17

0.15

1.17

1.27

-

-

-

-

-

-

-

-

-

800

0.66

1.25

1.38

0.52

1.42

1.51

0.31

1.60

1.64

0.08

1.80

1.78

-

-

-

900

0.99

1.48

1.60

0.87

1.70

1.77

0.69

1.92

1.93

0.47

2.18

2.09

0.19

2.45

2.23

950

1.20

1.61

1.71

1.08

1.86

1.90

0.90

2.12

2.07

0.72

2.39

2.23

0.41

2.67

2.42

1000

1.37

1.75

1.83

1.27

2.02

2.02

1.11

2.30

2.20

0.92

2.60

2.39

0.63

2.90

2.59

TABLE 4 - SUPPLY AIR BLOWER PERFORMANCE

1,3

(60 Hz Units)

RPM

CFM

ESP

2

BHP

KW

ESP

2

BHP

KW

ESP

2

BHP

KW

ESP

2

BHP

KW

ESP

2

BHP

KW

F3EH090

(50 Hz)

2000

2250

2500

2750

3000

500

0.22

0.43

0.41

0.16

0.48

0.46

0.08

0.53

0.50

-

-

-

-

-

-

542

0.30

0.47

0.45

0.25

0.53

0.50

0.18

0.58

0.55

0.10

0.63

0.60

-

-

-

550

0.32

0.48

0.46

0.27

0.54

0.51

0.20

0.59

0.56

0.12

0.64

0.61

0.01

0.70

0.66

600

0.42

0.54

0.51

0.38

0.60

0.57

0.32

0.66

0.62

0.23

0.72

0.68

0.13

0.78

0.73

650

0.54

0.60

0.57

0.50

0.66

0.62

0.45

0.73

0.68

0.37

0.79

0.74

0.28

0.85

0.80

700

0.67

0.67

0.63

0.63

0.73

0.69

0.58

0.80

0.75

0.52

0.87

0.82

0.43

0.95

0.89

732

0.77

0.71

0.67

0.73

0.77

0.72

0.68

0.84

0.79

0.62

0.93

0.87

0.54

1.02

0.96

750

0.83

0.74

0.69

0.79

0.80

0.75

0.73

0.87

0.82

0.68

0.97

0.91

0.60

1.07

1.00

F4EH120

(50 Hz)

2800

3150

3500

3850

4200

550

0.14

0.65

0.60

-

-

-

-

-

-

-

-

-

-

-

-

581

0.21

0.70

0.64

0.05

0.77

0.70

-

-

-

-

-

-

-

-

-

600

0.26

0.73

0.67

0.10

0.80

0.73

-

-

-

-

-

-

-

-

-

650

0.40

0.81

0.74

0.25

0.89

0.82

0.11

0.98

0.91

-

-

-

-

-

-

700

0.54

0.90

0.83

0.41

1.00

0.93

0.27

1.11

1.03

0.10

1.25

1.16

-

1.40

1.29

750

0.70

0.99

0.92

0.58

1.12

1.04

0.45

1.25

1.16

0.29

1.40

1.29

0.10

1.55

1.43

786

0.81

1.06

0.98

0.71

1.21

1.13

0.59

1.36

1.26

0.43

1.51

1.39

0.24

1.66

1.54

800

0.86

1.09

1.01

0.76

1.25

1.16

0.64

1.41

1.30

0.49

1.55

1.43

0.30

1.71

1.58

1

Unit resistance is based on a wet indoor coil and clean filters.

2

Available static pressure in IWG to overcome the resistance of the duct system and any accessories added to the unit. Refer to the Tables 6 & 7 for the resistance of these accessories and for

additional motor and drive data .

3

Motors can be selected to operate into the service factor because they are located in the moving air stream, upstream of any heating device.

TABLE 5 - SUPPLY AIR BLOWER PERFORMANCE

1,3

(50 Hz Units)

RPM range for the standard drive components.

Exceeds the BHP limitations of the standard blower motor.