Gas piping, Lgb-6 to lgb-20, Series 2 – control supplement – Weil-McLain LGB-20 User Manual

Page 4

LGB-6 to LGB-20

Series 2 – Control Supplement

4

Part Number 550-141-815/1010

II

Gas piping

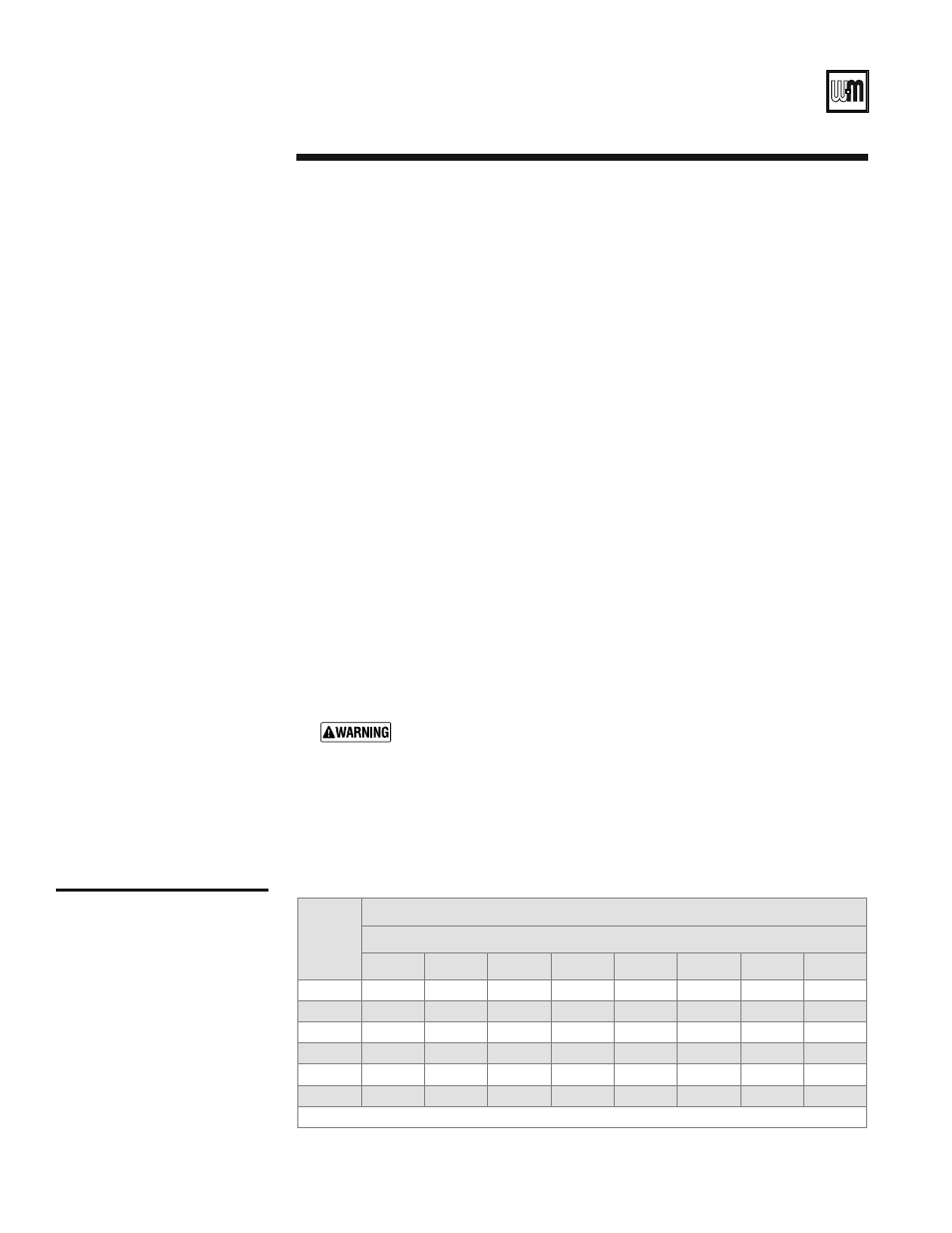

Table 3

Gas pipe sizing - natural gas

Do not check for gas leaks with an open flame – BUBBLE TEST. Failure

to use bubble test or test for leaks can cause severe personal injury, death

or substantial property damage.

1. Size natural gas piping from Table 3, below. Size piping to provide proper inlet pressure

to gas valve when operating at rated input.

a. Inlet gas pressure to manual main shut-off gas valve —

minimum 7” W.C. standard (5” W.C. on special order) – maximum 13” W.C.

b. If pressure to gas valve exceeds 13” W.C., install 100% lock-up gas pressure

regulator upstream of hand valve.

c. To obtain approximate cubic feet per hour, divide input (Btu/hr) by 1000.

2. Size gas piping considering —

a. Diameter and length of gas supply piping.

b. Number of fittings.

c. Maximum gas consumption (including any possible future expansion).

d. Allowable pressure drop from gas meter to boiler. For pressure drops, see ANSI

Z223.1. – latest edition.

3. Remove knockout disc from jacket panel through which gas supply will be piped.

4. Follow good piping practices.

5. Pipe joint compound (pipe dope) must be resistant to corrosive action of liquefied

petroleum gases. Apply sparingly only to male ends of pipe joints.

6. Install drip leg at inlet of gas connection to boiler. Where local code/utility requires,

extend drip leg to floor.

7. Install ground joint union when required for servicing.

8. Support piping by hangers, not by boiler or its accessories.

9. Purge all air from supply piping.

10. Before operating boiler, check boiler and its gas connections for leaks.

a. Close manual main shut-off valve during any pressure testing at less than 13” W.C.

b. Disconnect boiler and gas valve from gas supply piping during any pressure test

greater than 13” W.C.

Pipe

size

*Pipe length, in feet (Natural Gas capacities listed in MBH)

(Specific gravity 0.60 @ Pressure Loss of 0.30" W.C.)

10

20

30

40

50

75

100

150

1-¼”

1,050

730

590

500

440

360

305

250

1-½”

1,600

1,100

890

760

670

545

460

380

2”

3,050

2,100

1,650

1,450

1,270

1,020

870

710

2-½”

4,800

3,300

2,700

2,300

2,000

1,650

1,400

1,130

3”

8,500

5,900

4,700

4,100

3,600

2,900

2,500

2,000

4”

17,500

12,000

9,700

8,300

7,400

6,000

5,100

4,100

*Include measured length of gas supply piping and allowance in feet for number and size of fittings.