Optional equipment, Coolant system installation – Wilton 2221VS User Manual

Page 16

16

Optional Equipment

Coolant System Installation

1. Remove the large reservoir cover plate from the

machine base. Tap 1/4-20 threads in the 4 pilot holes.

Install the cover plate back onto the machine base.

2. Insert the pump into the opening, utilize the

screws from the small round cover plate to fasten the

pump to the base.

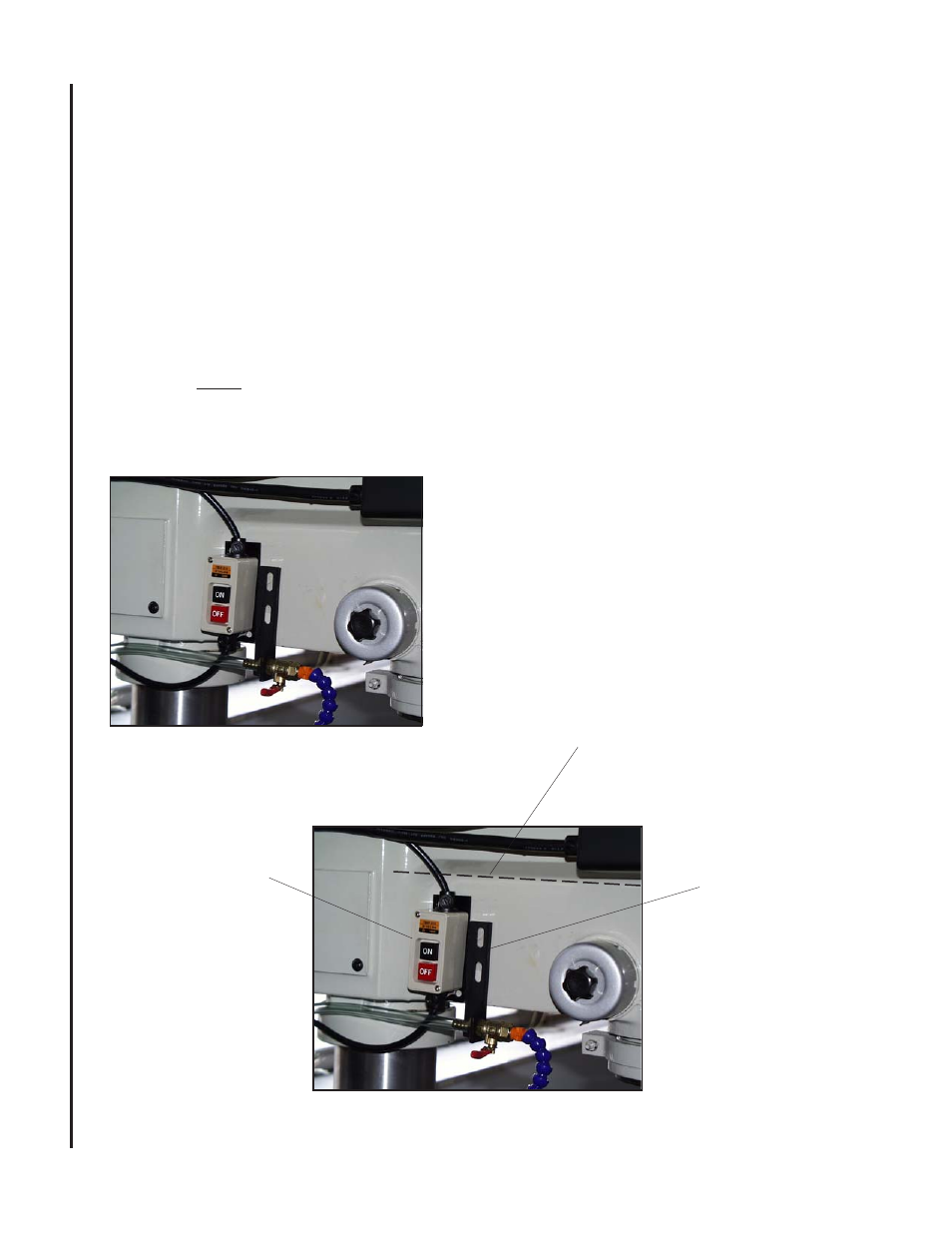

3. Position the power switch and valve bracket on the

spindle casting. Mark mounting hole locations and

drill holes. (Refer to Figure 8).

Note: Mount components near the lower edge of the

spindle casting. Do not mount componets above the

line shown in Figure 9.

4. Install the power switch and valve bracket with the

provided fastener hardware.

Figure: 8 Suggested installation

5. Install the 3/8-inch hose barb to the coolant pump.

If needed apply a light coat of pipe sealant or Teflon

tape to the threads to prevent leakage.

6. Mount the flow valve to the bracket, connect the

supply hose to the pump and valve, use hose clamps

at the ends.

7. Install the flexible nozzle to the flow valve.

8. Install the 1/2-inch hose barb to the worktable,

seal threads if needed. Connect the return hose.

9. Connect the power cord to a suitable source and

ground (refer to General Electrical Cautions).

10. Fill the reservoir with appropriate machining

coolant.

Figure 9: Installation Detail

Do not mount components

above this line.

Flow valve

mounting bracket.

Power switch - mounting

plate flush with bottom

edge of spindle casting.