Typical uses for the square wheel belt grinder, Optional features – Wilton 4103 User Manual

Page 9

9

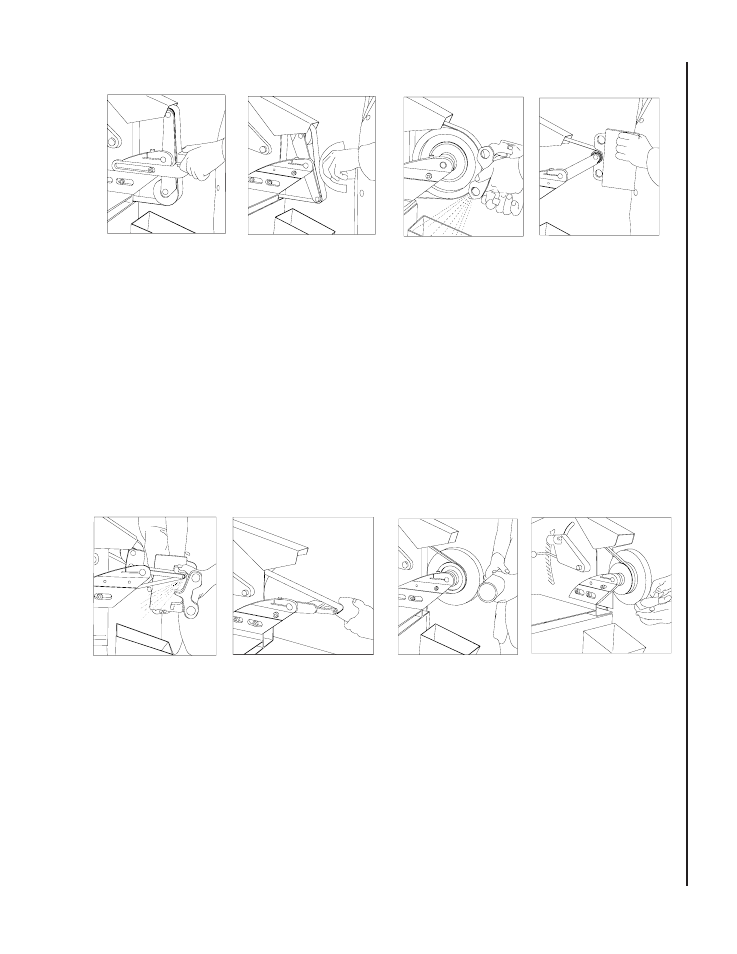

Typical Uses for the Square Wheel Belt Grinder

Flat or angular

stock — Platen

setting is the perfect

angle for high speed,

precision, flat and

level grinding of

tools, knives, plas-

tics, and other

materials. The platen

allows working to

very close toler-

ances. An adjustable

work rest is standard

on all models.

Shaping — For

grinding and finish-

ing cylindrical

shapes. The yoke

surface conforms to

the shape of the

surface to produce

an even, smooth

finish without the

danger of scarring.

Excellent for tool

post applications.

Roughing — Ser-

rated contact wheel is

used for removing

heavy stock, cleaning

up a weld or snag-

ging a casting. This

durable 8-inch

diameter wheel is

used extensively for

hollow grinding and

profiling knives and

other culinary tools.

It is standard equip-

ment on all models.

Contouring — Grind

difficult, hard to

reach areas with the

3-inch by 2-inch or 1-

1/2 inch by 2-inch

diameter contact

wheels. Contours

and shapes unique

parts like propellers

and metal furniture.

OPTIONAL FEATURES

Internal contouring

— The air-cushioned

dead head is for use

on very small radius

grinding. When

connected to a

source of shop air

(80-90 psi), the belt

rides on a cushion of

air to decrease head

and belt wear. The

dead head is easy to

use, and adapts to

any of the available

radius tips.

Internal contouring with

small wheel — This small

wheel accessory is

designed for hard to reach

places. Includes 5/8-inch,

70 durometer contact

wheel. Available contact

wheels are 1/2-inch, 3/4-

inch, and 1-inch.

Polishing — The

buffing pad is perfect

for satin finish or high

gloss polishing. The

fine, close stitched

burring pads are ideal

for metal and plastic

Finishing — The nylon

reinforced, silicone

carbide wheel is

perfect for polishing

and deburring. It

applies a high luster

finish on rough sur-

faces and is excellent

for steel, iron, or

aluminum.