Air cushioned dead head assembly – Wilton 4103 User Manual

Page 19

19

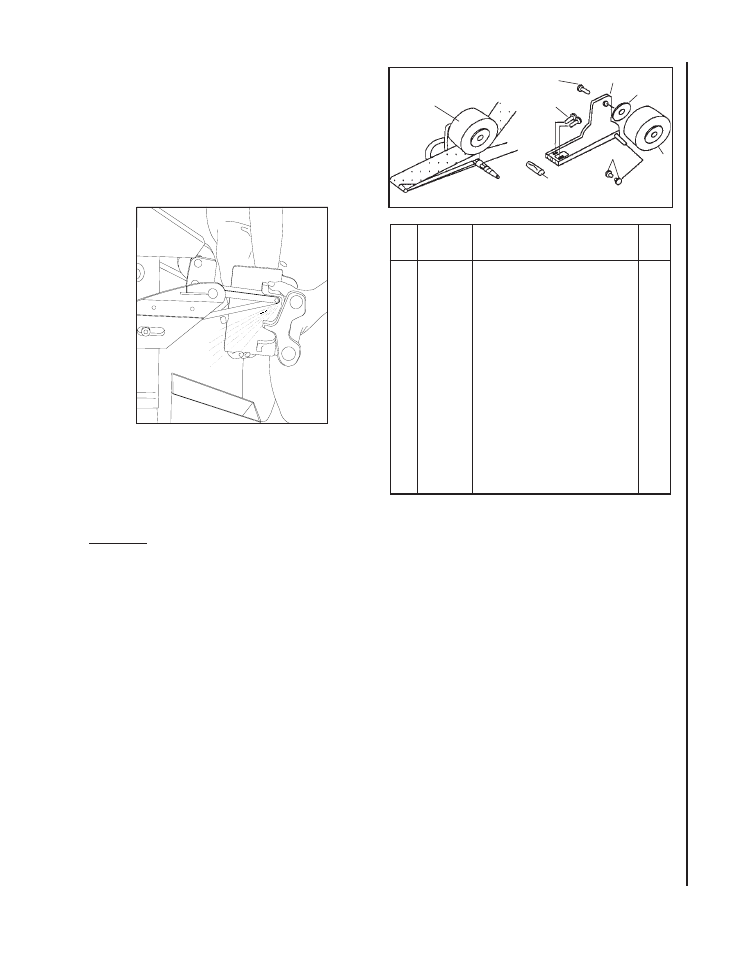

Air Cushioned Dead Head Assembly

Refer to Figures 10 and 11. The air-cushioned dead

head is for use on very small radius grinding. When

connected to a source of shop air (80-90 psi), the

belt rides on a cushion of air to decrease head and

belt wear. The dead head is easy to use, and adapts

to any of the available radius tips.

Figure 11: Air Cushioned Dead

Head Assembly Parts Breakdown

1

2

5

3

4

6

8

7

Ref. Part

No. Number

Description

Qty.

1

5044960

Air Cushion Dead Head

1

Assembly (Note 1)

2

5044970

Casting, Dead Head

1

3

5044991

Tip, Dead Head, 3/16 R x 2

1

5045011

Tip, Dead Head, 1/4 R x 2

1

5045031

Tip, Dead Head, 5/16 R x 2

1

5045051

Tip, Dead Head, 3/8 R x 2

1

4

5045071

Fitting, Flareless Com-

1

pression, 1/4 x 1/8

5

5044610

Contact Wheel Assembly

1

3 x 2

6

5045101

Spacer

1

7

9062441

Screw, Socket Head Cap

2

10-32 x 1/2

8

9049761

Screw, Socket Head Flare

1

Note 1: Includes 3/8 R x 2 dead head tip 5045051.

Other tips available at additional cost.

Install the dead head assembly as follows:

WARNING: DISCONNECT ELECTRICAL POWER

TO THE MACHINE BEFORE INSTALLING THE

DEAD HEAD ASSEMBLY.

1. Lower tension lever to release belt tension.

2. Loosen clamping screw and remove platen or

contact wheel.

3. Insert the shaft of the dead head assembly in

head casting. Position dead head assembly

with the tip parallel with the machine base.

Tighten the clamping screw.

4. Install the belt under the dead head contact

wheel and over the dead head tip.

5. Lift the tension lever to tighten the belt.

6. Check belt tracking.

7. Connect pressurized air supply (80-90 psi).

8. Check operation of the dead head assembly.

Figure 10: Internal Contouring

with Air Cushioned Dead Head