Troubleshooting – Wilton 41002 User Manual

Page 19

19

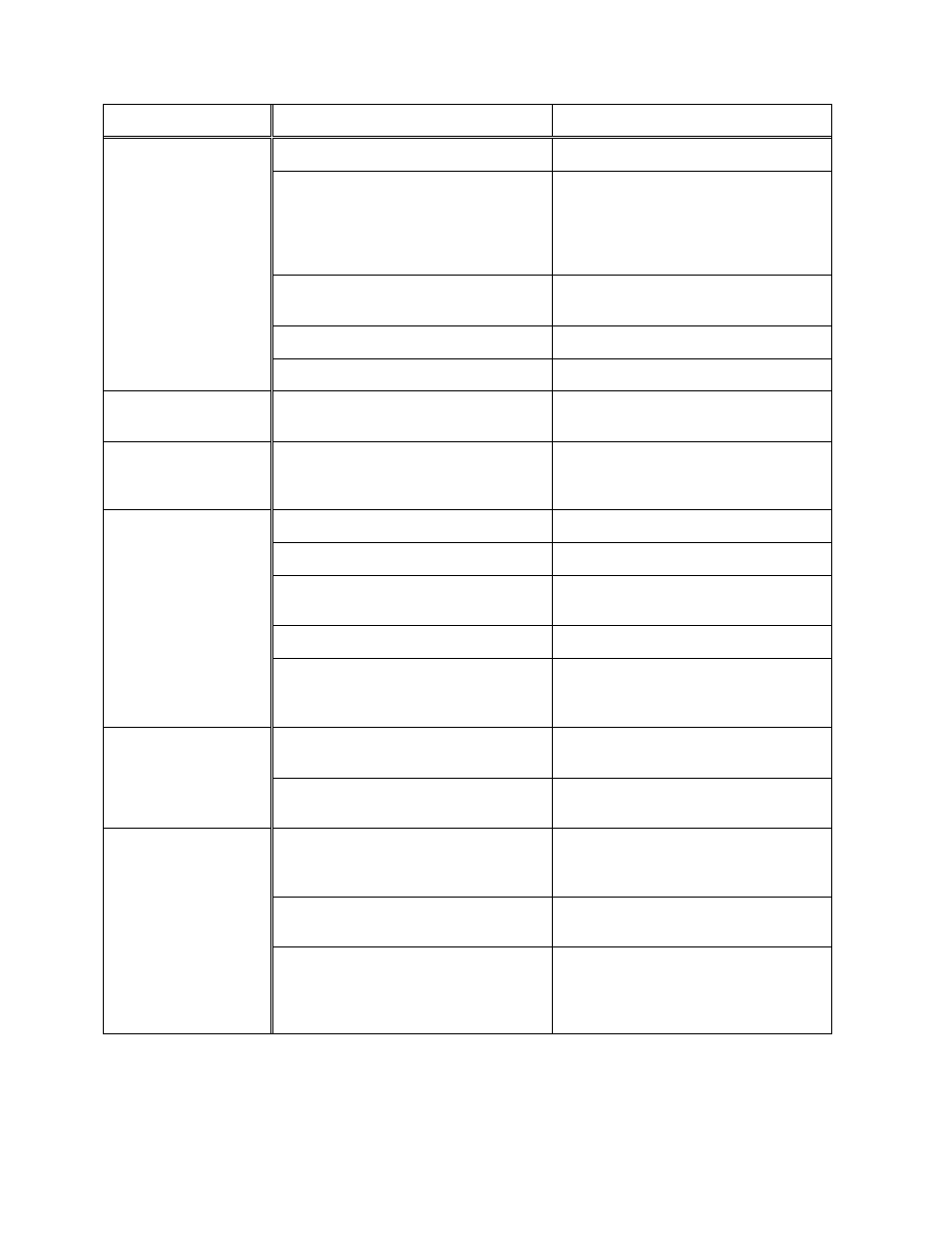

Troubleshooting

Trouble Probable

Cause

Remedy

Not connected to power source.

Connect to power source.

Branch circuit fuse is blown or the

circuit breaker is tripped.

Determine reason for blown fuse/

tripped breaker (such as short circuit

or motor overload). Correct reason for

fault. Replace fuse/ reset circuit

breaker.

Voltage is too low.

Check power source for proper

voltage.

Switch is defective.

Replace switch.

Sander will not start.

Motor failure.

Replace motor.

Motor stalls easily.

Low voltage.

Check power source for proper

voltage and correct if necessary.

Abrasive disc

separates from

aluminum disc.

Improper bond.

Clean residual adhesive from

aluminum disc, and re-apply

adhesive-backed abrasive disc.

Belt not centered on wheels.

Readjust tracking. See page 14.

Belt stretched unevenly.

Replace abrasive belt.

Belt is jointed improperly.

Check the belt for an irregular seam

or shape. Replace if needed.

Wheel is worn.

Replace affected wheel.

Abrasive belt will not

track correctly.

Worn bearings.

Check all the bearings for excessive

heat or loose shafts. Replace if

necessary.

Abrasive belt tension inadequate;

spring in tension mechanism is worn.

Replace spring.

Abrasive belt slips or

stalls when pressure

is applied.

Excessive pressure being applied to

platen.

Reduce pressure on abrasive belt

(and platen).

Too much pressure being applied to

workpiece.

Allow the belt to do the cutting.

Excessive pressure only dulls the grit

and removes it from the cloth.

Full width of belt or disc not being

used.

Stroke across abrasive belt using full

width of belt surface.

Frequent

replacement of

abrasive belt or disc.

Incorrect abrasive material or grit

size.

Check with your abrasives supplier for

recommendations on the type and

coarseness of the abrasive required

for your particular workpieces.