Use of the miter gauge, Belt platen – Wilton 41002 User Manual

Page 13

13

4. Tighten both handles securely.

To avoid trapping the

workpiece or fingers between the table and

abrasive disc, the table edge should be

positioned a maximum of 1/16” from the

abrasive disc.

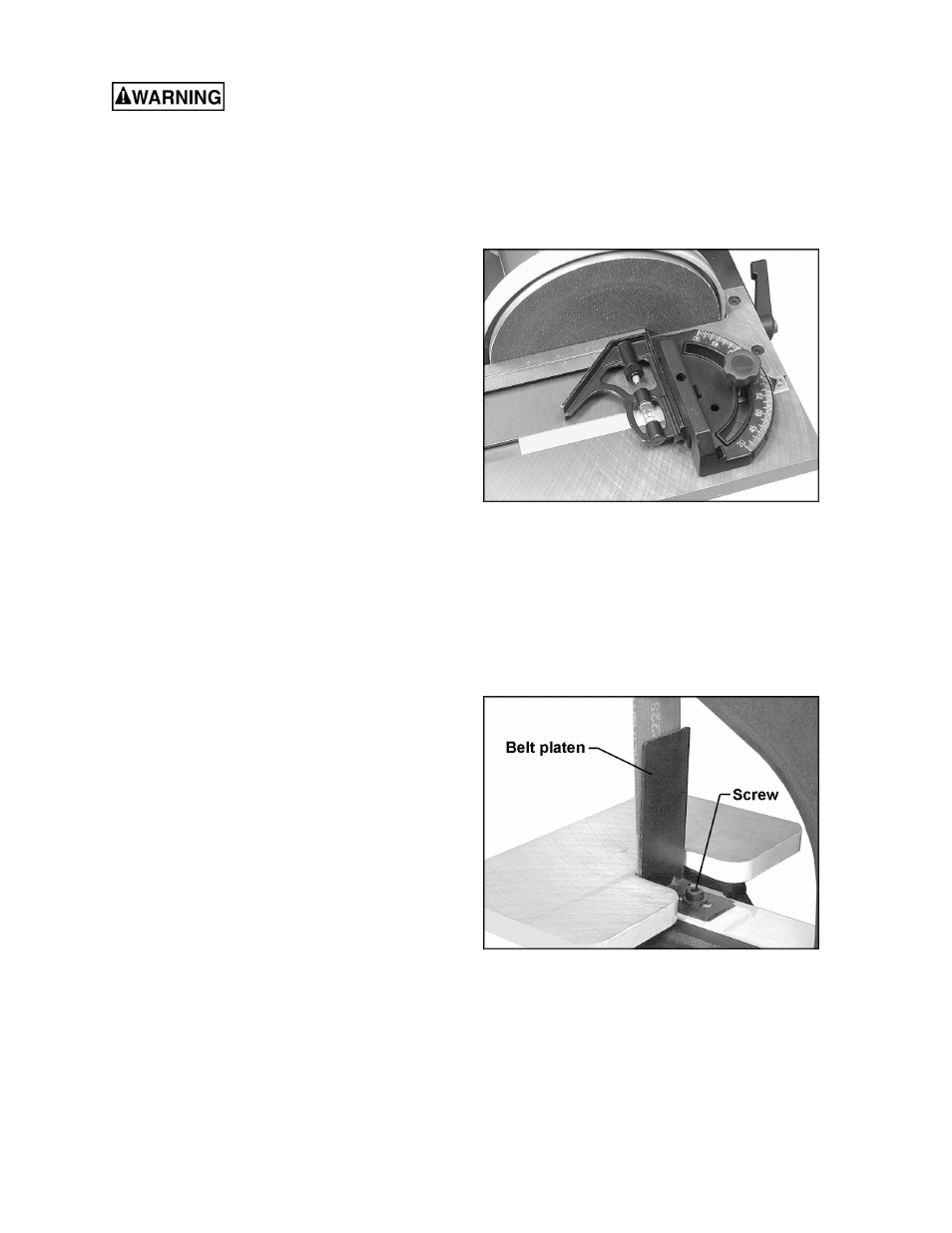

Use of the Miter Gauge

The miter gauge is used to sand accurate

angles on workpieces. When using the miter

gauge on the horizontal table position, you can

sand a single angle. By tilting the disc table and

using the miter gauge in combination with the

table tilted, it is possible to sand compound

angles as well.

The miter gauge rotates to 30° for bevel

sanding. Loosen the knob and rotate the gauge

body until the pointer lines up with the desired

angle on the scale.

Use a square to confirm that the miter gauge is

set at 90° (perpendicular to the disc). See Figure

12. If slight adjustment is needed:

1. Loosen the knob.

2. Adjust the miter gauge body until it is flush

with the square, and the square is flush with

the disc.

3. Tighten

the

knob.

4. Loosen the screw on the pointer and adjust

the pointer until it aligns with 90° on the

scale.

5. Tighten the screw on the pointer.

Belt Platen

The belt platen (Figure 13) is used to properly

support the workpiece while sanding. The platen

is constructed of heavy steel to provide

adequate support.

The platen should be adjusted so it is almost

touching the back of the abrasive belt. Loosen

the socket head cap screw and adjust the platen

to the desired position. Tighten the screw to

secure the platen.

The platen can be removed for operations such

as stripping, contour sanding, polishing or other

special operations. To remove the platen,

remove the socket head cap screw and washer.

Be sure to re-install the platen to perform

operations where support of the belt is required.

Figure 12

Figure 13