Adjusting guide bearings, Replacing guide bearings, Adjusting blade back-up bearings – Wilton 3410 User Manual

Page 18

18

Adjusting guide bearings

There are eight side blade guide/support bearings.

These bearings are installed in the bearing seat, and the

seat is attached to the sliding adjustment bracket.

These bearings are stacked, with two bearings on

each adjustment eccentric. The width of each pair of

stacked bearings is slightly less than the width of a blade.

The force against each of the bearings in each

stack is not equal. This is because the bearings are

twisting the blade. This puts a much higher force against

the two bearings which are doing most of the twisting.

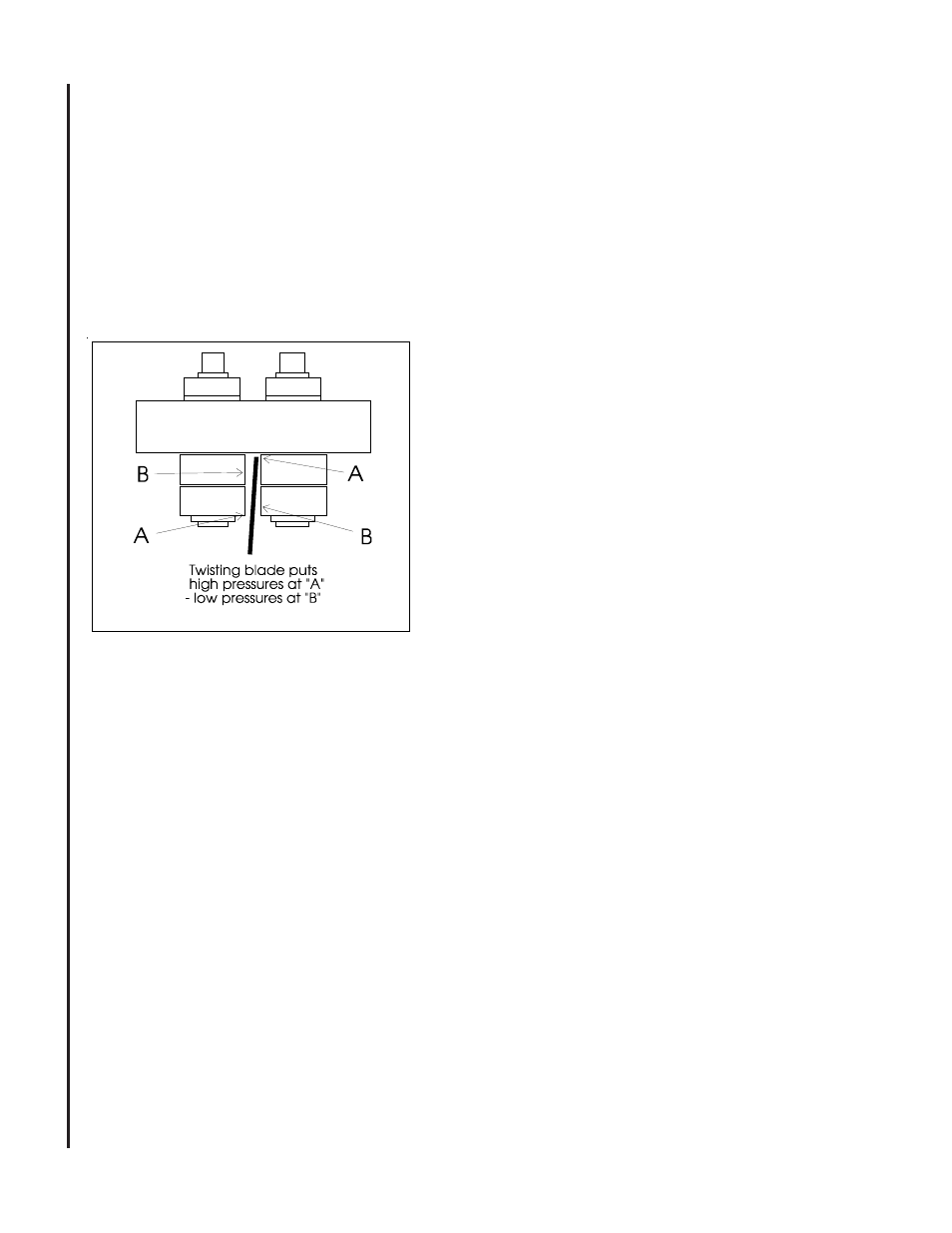

Look at Figure 15 for a diagram which shows this effect.

Figure 15: Guide bearing forces. Blade twist and clear-

ance is exaggerated for demonstration. In practice, the

blade will be standing vertical between the bearings when

they are adjusted correctly.

The bearings are adjusted by moving the eccentrics

as required, and by using your fingers to twist the bear-

ings to see if they can rotate, and how difficult it is to

rotate them.

The bearing clearance is correctly adjusted when

the bearings labeled with an "A" in Figure 15 cannot be

turned at all, and when bearings labeled with a "B" in

Figure 15 can barely be turned with your fingers.

If the supporting bearings don't turn at all -- the set-

up is too tight. If they can be turned easily using your

thumb and forefinger -- the set-up is too loose.

To adjust:

1. Put a wrench on the adjustment tang of the bearing set

you want to adjust. This prevents the eccentric from

turning.

2. Use another wrench to loosen the lock nut for the

eccentric bolt.

3. Turn the eccentric using the adjustment tang to loosen

or tighten the bearing set, as needed.

4. Tighten the jam nut.

5. Check bearing tightness on both sides of the blade.

Re-adjust as required until the conditions described in the

above paragraphs is obtained.

Replacing guide bearings

1. Remove the blade as outlined in steps 1 through 6 of

Replacing blades.

2. Remove the jam nut on the eccentric upon which you

are going to replace bearings.

3. Remove the clip which secures the bearings on the

eccentric shaft.

4. Tap the old bearings off and press the new bearings

on.

5. Replace the snap ring which secures the bearings on

the eccentric.

6. Reinstall the eccentric in its position and tighten the

jam nut loosely on the eccentric.

7. Install the blade according to instructions 7 through 14

in Replacing blades.

8. Adjust bearing clearance according to instructions in

the previous section: Adjusting guide bearings.

Adjusting blade

back-up bearings

The back-up bearings support the rear of the saw

blade as it takes the pressure of cutting. (Refer to

Figure 11.)

1. Being careful not to disturb the vertical angle of the

guide bearing seat, loosen the socket head cap screw

which secures the seat.

2. Move the seat downward until the back-up bearing just

barely touches the back of the blade.

3. Tighten the socket head cap screw securely.

4. Perform this same operation on the other back-up

bearing, if required.

After adjusting the back-up bearings, CHECK FOR

BLADE VERTICAL according instructions in Adjusting

blade vertical. It is very easy to disturb the vertical plane

of the blade while performing this adjustment, and a blade

which is not vertical will NOT cut straight.