Troubleshooting, Control supplement & service guide – Weil-McLain ULTRA 230 User Manual

Page 27

27

Part number 550-100-029/0810

GAS

-

FIRED

WATER

BOILER

SERIES

1 & 2

— Control supplement & Service guide

Troubleshooting

(continued)

Instructions in this supplement are based

on factory default parameter settings.

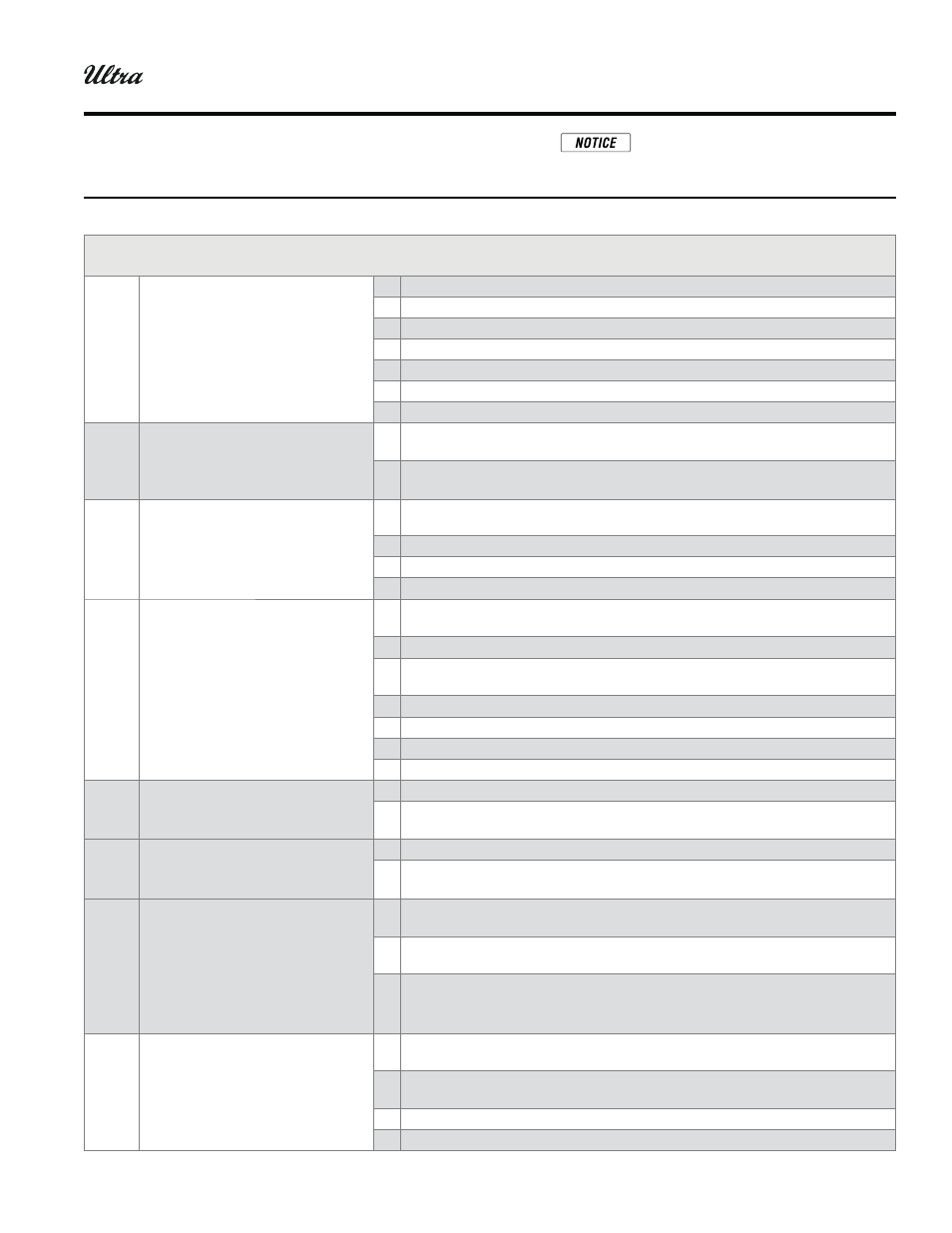

SOFT LOCKOUT

[Display flashes 9, then b in first position; last two digits on steady (code)]

25

Outlet water temp rose too quickly

— burner off for 10 minute wait

(burner recycles, increasing wait 1

minute each attempt, to a max of

15 minutes)

1

Possible hot water return from DHW tank.

2

Make sure system does not have trapped air preventing proper flow.

3

Inspect and verify system piping and components.

4

Verify piping agrees with boiler manual recommendations.

5

Verify proper circulator(s) operation.

6

Possible loose connector on boiler outlet sensor. Tighten connector.

7

Possible bad boiler supply outlet sensor.

26

External limit open on limit wired

in soft lockout circuit (auto reset).

Low voltage terminals 6 and 7.

Burner off for 150 seconds

1

If no external limit connected to 6 & 7, verify green jumper wire making good electrical

contact with screw terminals.

2

If external limit connected, verify proper limit operation.

29

Blower signal not zero when it

should be — Burner off until signal

condition corrected

1

Change display to Information mode — if INFO #6 shows 6._32, the blower has

failed.

2

Possible strong wind blowing against vent turning blower wheel, correct venting.

3

Defective blower.

4

Defective control module.

30

Temperature rise across boiler

more than 45°F. — Burner off for

150 second wait (plus 1 additional

minute for each failed attempt,

up to 20 times, then hard lockout

occurs

1

Flow problem through boiler — Temperature rise through boiler should be less than

35°F.

2

Make sure system does not have trapped air preventing proper flow.

3

Inspect and verify system piping and components (including pipe size and circulator

capacity).

4

Verify piping agrees with boiler manual recommendations.

5

Verify proper circulator(s) operation.

6

Possible loose connector on boiler supply/return sensor(s). Tighten connector.

7

Possible bad supply/return sensor — replace sensor.

35

Short circuit across flue

temperature sensor terminals —

Burner off until corrected

1

Shorted wiring to flue sensor— correct the wiring.

2

Defective flue sensor — replace sensor.

40

Open circuit across flue

temperature sensor terminals —

Burner off until corrected

1

Shorted wiring to flue sensor— correct the wiring.

2

Defective flue sensor — replace sensor.

52

Flue Temperature exceeded 216 °F.

but did not exceed 225 °F (hard

lockout occurs above 225 °F —

Burner off for 150 second wait

1

Verify flue temperature with thermometer. If actual temperature does not correlate with

Information mode #5 replace flue sensor.

2

Heat exchanger may need to be cleaned. Follow the boiler maintenance procedure given

in this guide, page 33.

3

Burner problem — verify gas pressure, burner firing rate and combustion per Ultra

Boiler manual procedures — correct any problems.

If combustion is not acceptable, see page 38 in this guide.

65

Waiting for blower to start

1

Change display to Information mode — if INFO #6 shows 6._32, the blower has

failed.

2

Verify blower wiring, 120 VAC on high voltage connector, if no120VAC, inspect/replace

wire harness, or control module.

3

Defective blower.

4

Defective control module.

&IGURE

Troubleshooting procedures — when display shows soft lockout code (continued)