Wilton PF3-EZ User Manual

Page 14

14

General Operating Instructions

1. Make sure all locking handles are tight

before operating the Stock Feeder.

2. The Stock Feeder should be used in

conjunction with a fence on the table saw.

3. The rollers must grip the offcut as well as

the part of the workpiece being fed.

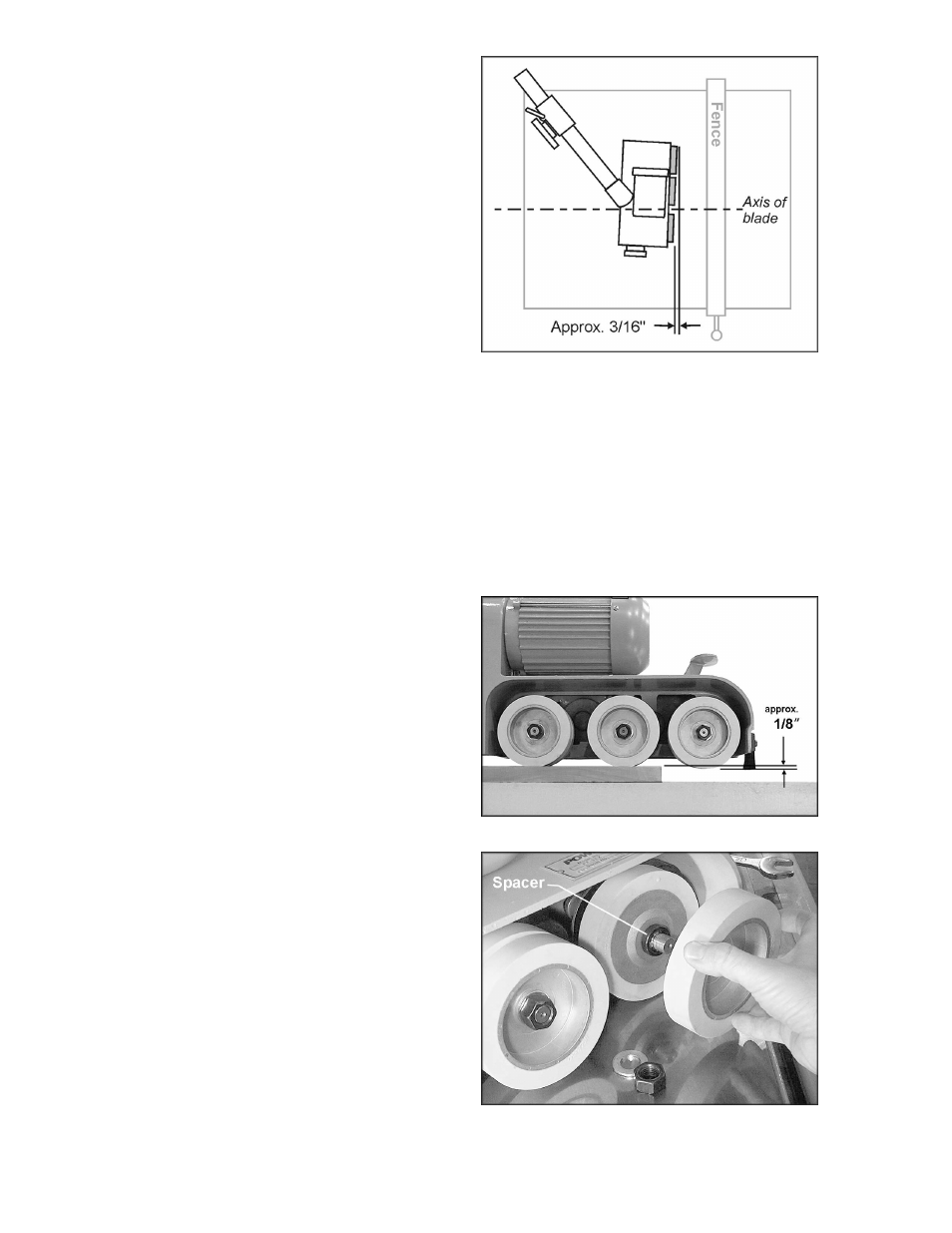

4. Position the Stock Feeder so that the axis of

the saw blade lines up between the infeed

roller and center roller. See Figure 13. This

will allow the Stock Feeder to grip the near

part of the workpiece as it enters the blade,

as well as the offcut of the workpiece as it

leaves the blade.

5. Rotate the Stock Feeder so that the

direction of feed is angled slightly toward the

fence by approximately 3/16” (5mm); that is,

the outfeed roller should be slightly closer to

the fence than the infeed roller. See Figure

13.

IMPORTANT: Do not position the stock

feeder in such a way that the rollers will

interfere with, or be damaged by, the blade.

6. The Stock Feeder should be adjusted for

height so that the distance between the

table and the feed rollers is approximately

1/8” (3mm) less than the thickness of the

workpiece. See Figure 14.

7. The feed rollers have a spring suspension,

which will exert the necessary pressure

against the workpiece. This pressure

increases automatically with feed

resistance, so that a workpiece of varying

thickness can be fed through the Stock

Feeder without adjustments.

8. If a workpiece becomes jammed during

cutting operation, shut off the table saw and

the Stock Feeder. Then raise the Stock

Feeder, remove workpiece, re-position the

Stock Feeder and begin the cutting

operation again.

9. Using hardwood with the Stock Feeder may

increase the friction between workpiece and

saw table. Keep the saw table rust-free and

smooth by using paste wax or other

necessary means.

Spacers

Three spacers are included with the Stock

Feeder. These are used to increase the kerf

spacing between inner and outer rollers. See

Figure 15.

Figure 13

(guard removed for clarity)

Figure 14

Figure 15