Battery information, Installation, Continued) – Wayne 352205-001 User Manual

Page 2

Battery Information

(Continued)

Be certain that the area around the

batteries is well ventilated. Before

servicing the batteries, blow away

gasses by waving a piece of cardboard

near the batteries.

Dangerous hydrogen gas can be

released from batteries while charging.

Sparks can ignite the gas in an

enclosed space. Wear safety goggles

when connecting batteries. Battery

connections should be made in a well-

ventilated area.

Working in the vicinity of lead acid

batteries can be dangerous. Before

making connections or servicing the

batteries, read and follow instructions

in all applicable instruction manuals. To

reduce the risk of battery explosion,

follow the instructions in this manual

and those published by the battery

manufacturer, as well as those of any

other equipment used in the

surrounding area.

An assistant should be present or close

enough to come to your aid in the

event of an emergency. Have a reliable

source of fresh water and soap nearby

in case battery acid contacts clothing,

skin or eyes.

Wear eye and clothing protection

when working around lead acid

batteries.

Avoid touching your eyes when

working around lead acid batteries.

If battery acid contacts your eye(s),

flush with cold running water for 10

minutes and seek immediate medical

attention. If acid contacts your skin or

clothing, wash immediately with soap

and water.

Never smoke or allow a spark or flame

in the vicinity of the battery.

Avoid dropping metal tools on the

battery posts because they may spark

or short-circuit the system or battery,

causing an explosion.

Installation

Installation of this unit may take

several hours. Before disabling your

main pump, have ready an appropriate

means of evacuating the sump.

1. Turn power to main pump off.

2. Pump must be installed using 1

1

/

4

”

or 1

1

/

2

” rigid PVC piping.

Pump Installation

The ESP25 can be installed as a back up

system with a separate dedicated

discharge line (Method 1), or tied into

an existing sump pump line (Method 2,

page 3).

Unplug the existing AC pump. Failure to

follow this warning could result in fatal

electrical shock.

1. Verify that the existing AC pump is

in good working order. If the AC

pump is questionable, it is typically

recommended that the unit be

replaced with a 1/3 or 1/2 HP pump.

2

Operating Instructions and Parts Manual

2. Remove any silt or accumulated

debris from the sump pit and

surrounding area.

Method 1 (Preferred)

1. Locate the ESP25 on a solid, level

surface in the sump pit. Do not

place the pump on a loose or sandy

surface. Small stones or sand may

damage the pump resulting in

potential pump failure.

2. This pump has a 1

1

/

2

” NPT discharge.

If a 1

1

/

4

” discharge pipe is desired, an

adapter (not included) will be

necessary. Smaller diameter piping

will reduce pump flow, rate and

performance.

3. Cut a 4’ section of 1

1

/

4

" or 1

1

/

2

"

diameter rigid PVC pipe. Cement

1

1

/

4

" pipe to a threaded fitting.

Cement 1

1

/

4

" pipe into pipe

coupling. Attach 1

1

/

4

" pipe section

to the ESP25 discharge adapter.

4. Screw on to pump discharge.

www.waynepumps.com

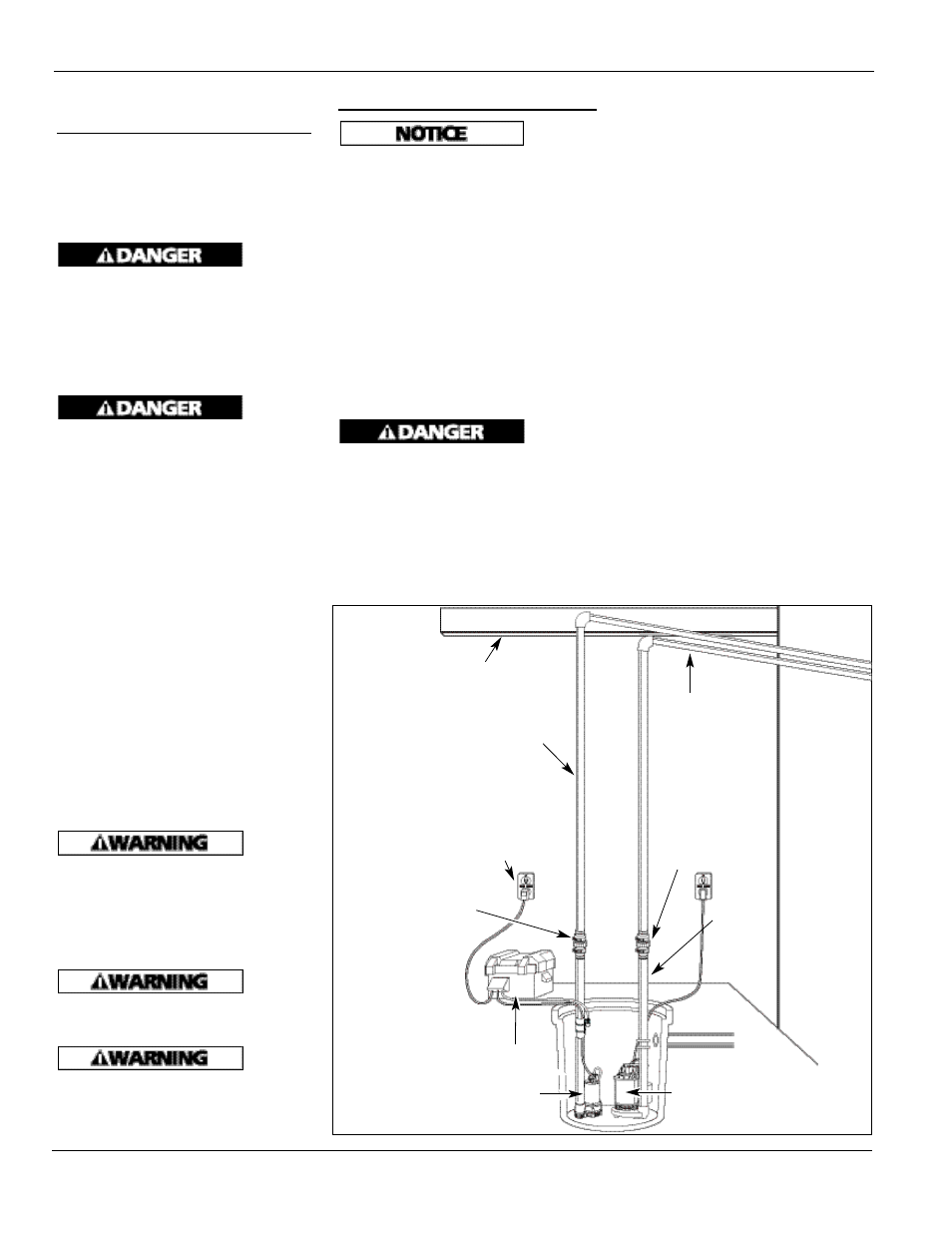

Figure 1 - Method 1

Floor

Joist

Charger

Ridgid

PVC

Pipe

Check Valve

(See Step 6)

1

1

/

4

” or

1

1

/

2

”

PVC Pipe

ESP25 Pump

Existing Pump

Check Valve

(See Step 6)

Slope

Pipe

Down

Battery Box