12 volt wiring diagram, 12 volt dc pump, Inlet outlet – Wayne PC2 Series User Manual

Page 3: Pc1 and pc2 series

PC1 and PC2 Series

www.waynepumps.com

operation (Continued)

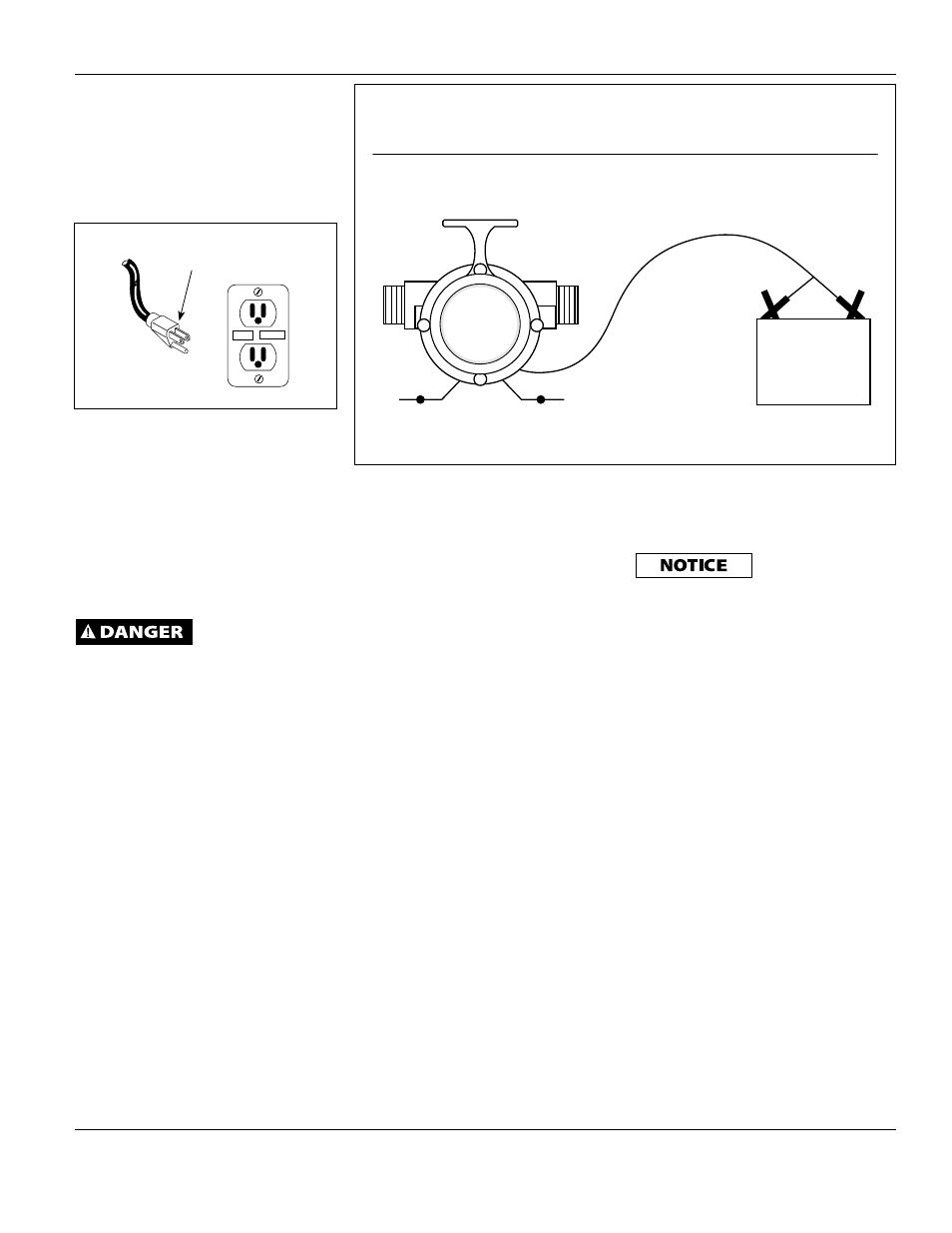

4 . . Connect .pump .to .power .source, .

with .pump .in .a .dry .location . .Model .

PC1: .Motor .must .be .connected .to .a .

fully .charged .automotive .tractor .or .

marine .type .battery .to .operate . . .

.

Connect .the .red .clamp .to .the .

positive .(+) .type .battery .terminal . . .

Connect .the .black .clamp .to .the .

negative .(-) .type .battery .terminal . .

See .12V .wiring .diagram .below .

(Figure .2) . .

Model PC2: Plug .into .a .

3-prong .ground-type .AC .receptacle .

Maintenance

Always disconnect

power source

before attempting to install, service, or

maintain the pump.

IMPeller rePlaCeMenT

These .parts .are .designed .to .handle .

most .clear, .nonflammable .liquids .with .

slight .amounts .of .abrasives . . .When .

impeller .vanes .become .worn .from .use, .

or .damaged .due .to .pumping .abrasive .

liquids .or .trash, .pump .performance .will .

be .reduced .or .prevented .altogether . .

1 . . Remove .the .four .cover .plate .screws .

holding .motor .housing .and .pump .

housing .together . . .Cover .plate .is .

now .free .and .can .be .removed . . .

2 . . Inspect .gasket .and .impeller .for .

wear .and .damage . . .If .there .is .any .

evidence .of .wear .or .damage, .replace .

the .part(s) . .

3 . . Lubricate .new .impeller .with .white .

grease .or .lightweight .oil .and .

reinstall .by .aligning .flat .on .impeller .

hub .with .flat .on .motor .shaft . .

4 . . Reassemble .gasket, .cover .plate, .and .

cover .plate .screws .

ShafT Seal rePlaCeMenT

Motor .shafts .are .sealed .with .factory .

pre-lubricated .lip-type .seals .which .are .

good .for .the .life .of .the .pump . . .If .the .

seal .leaks, .it .is .usually .because .the .pump .

has .handled .abrasive .liquids . . .If .the .

motor .shaft .is .scored .(deep .grooves), .

the .complete .pump .must .be .replaced . . .

1 . . . Remove .and .inspect .impeller .parts .as .

specified .in .the .impeller .replacement .

instructions . . .Replace .worn .parts . . .

2 . . . Remove .two .pump .body .mounting .

screws .and .slide .pump .body .from .

motor . . .Pry .out .seal .retaining .ring .

and .push .worn .shaft .seal .from .inside .

of .pump .body . .

3 . . . Lubricate .new .seal .with .lightweight .

oil, .push .it .into .pump .body .with .lip .

facing .away .from .motor, .and .push .in .

seal .retaining .ring . .

4 . . . Reassemble .pump .body .onto .motor .

with .mounting .screws . .Follow .steps .

3 .and .4 .in .Impeller .Replacement .

MoTor BrUSh rePlaCeMenT

Brushes for this

pump should be

inspected after 75 hours of operation

and replace if worn. They must be

replaced every 100 hours of operation.

Service one brush at a time.

1) . Disconnect .pump .from .power .

supply .

2) . Remove .brush .caps .with .screwdriver .

3) . Remove .old .brush .assembly .

4) . Insert .new .brush .assembly .

5) . . .Replace .brush .caps .

TEST

RESET

Grounding .Plug

figure 1

12 VOLT WIRING DIAGRAM

RED CLAMP

TO POSITIVE

TERMINAL

BLACK CLAMP

TO NEGATIVE

TERMINAL

POS

+

12 VOLT DC

BATTERY

-

NEG

12 VOLT DC PUMP

INLET

OUTLET

figure 2