24 dealer service – Woods Equipment RD6000-2 User Manual

Page 26

24 Dealer Service

MAN0180 (Rev. 1/7/2005)

Remove Gearbox from Mower

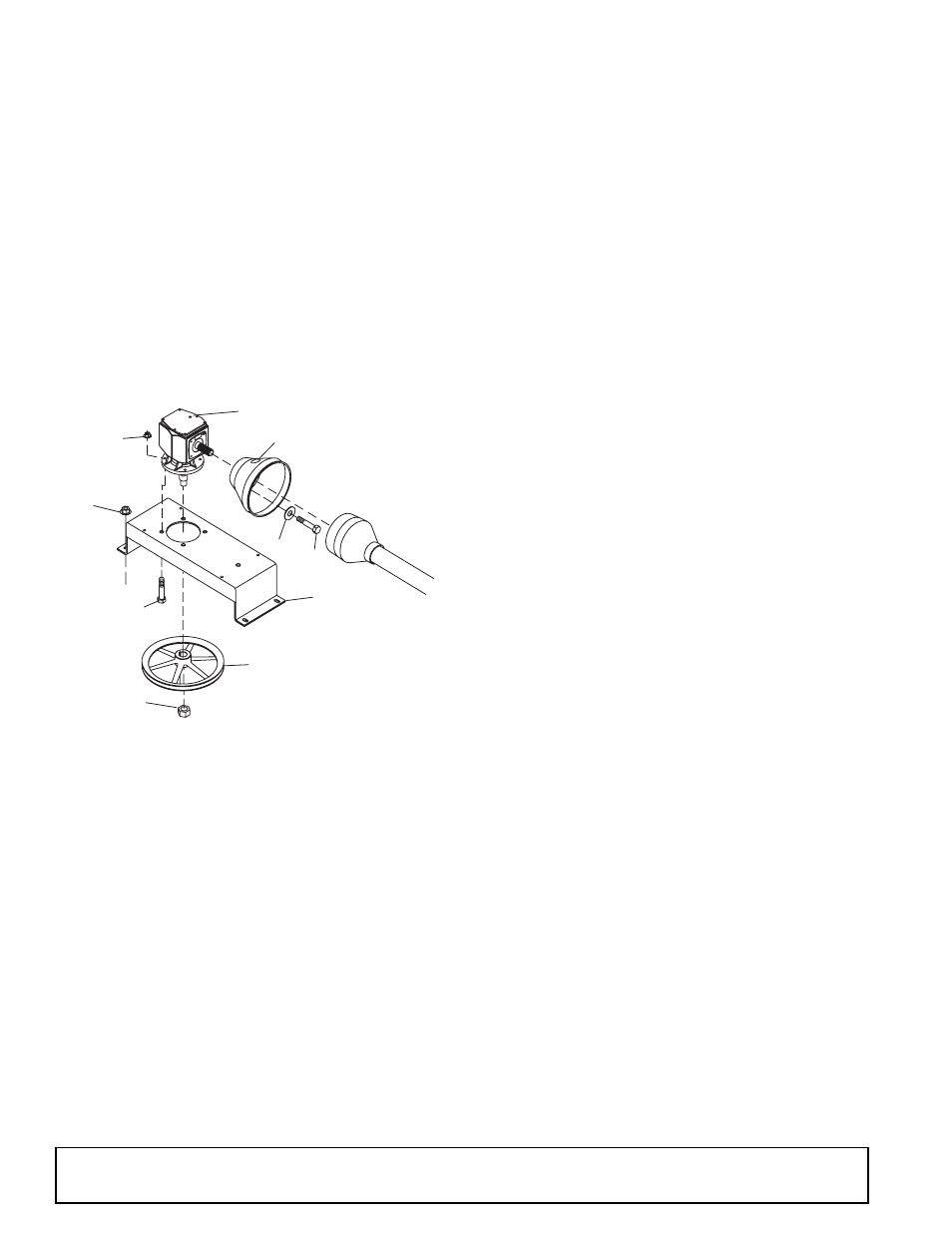

Refer to Figure 22.

1. Disconnect and remove the rear driveline from the

gearbox.

2. Remove vent plug and siphon gear lube from

housing through this opening.

3. Remove gearbox stand (20) from mower deck by

removing four flanged lock nuts (56).

4. Remove four cap screws (43) and washers (42)

and remove shield (22) from gearbox.

5. Remove castle nut and hardware from output shaft

of gearbox.

6. Remove sheave (19) from gearbox.

7. Remove four bolts (63) that attach gearbox to

gearbox stand and remove gearbox.

Figure 22. Gearbox Stand Assembly

Disassemble Gearbox

1. Remove top cover (22) from housing. Turn gearbox

upside down and pour out remaining gear oil from

gearbox.

2. Remove oil cap (20) (to be replaced).

3. Remove snap ring (10) and shim (13) from input

shaft (3).

4. Support gearbox in hand press and push on input

shaft (3) to remove bearing (7).

5. Remove gear (1) from inside housing.

6. Remove oil seal (19) from front of housing (to be

replaced).

7. Remove snap ring (10) and shim (13) from front of

housing (2).

8. Remove input bearing (7) by using a punch and

hammer from outside of housing.

9. Support housing in vise in a horizontal position.

10. The castle nut (15) and cotter pin (25) are already

removed with the drive sheave. Remove the snap

ring (21), washer (8), and seal (18).

11. Remove cotter pin (9), castle nut (14), and washer

(17) from output shaft (4).

12. Remove output shaft (4) by using a punch and

hammer and tap on top to drive down.

13. Remove gear (5) and shim (16) from inside

housing.

14. Remove bearing (26) by using a punch and

hammer from the top, outside the housing.

15. Support housing upside down (top cover surface)

and remove bearing (6) by using a punch and

hammer from the bottom side of the housing.

16. Inspect gears for broken teeth and wear. Some

wear is normal and will show on loaded side.

Forged gear surfaces are rough when new. Check

that wear pattern is smooth.

17. Inspect vertical and horizontal shafts for grooves,

nicks, or bumps in the areas where the seals seat.

Resurface any damage with emery cloth.

18. Inspect housing and caps for cracks or other

damage.

Reassemble Gearbox

Refer to Figure 23

NOTE: Repair to this gearbox is limited to replacing

bearings, seals, and gaskets. Replacing gears, shafts,

and a housing is not cost effective. Purchasing a com-

plete gearbox is more economical.

1. Clean housing, paying specific attention to areas

where gaskets will be installed.

2. Wash housing and all components thoroughly.

Select a clean area for gearbox assembly. Replace

all seals, bearings, and gaskets. All parts must be

clean and lightly oiled before reassembling.

3. Insert output bearings (6 & 26) in the housing,

using a round tube of the correct diameter and a

hand press.

4. Slide output shaft (4) through both bearings (6 &

26) until it rests against bearing (6).

5. Slide shim (16) over output shaft (4).

56

59

22

42

43

63

19

CD4986A-1

Vent Plug

20

Castle Nut

19. Sheave, offset 12.4 PD

20. Gearbox stand

22. Shield, counter cone

42. Washer, flat standard 5/16

43. Screw, HHCS 8mm x 1.25P x 16mm

56. Nut, flanged lock 1/2 NC

59. Nut, flanged lock 5/8 NC

63. Screw, Flanged Hex Head 5/8 NC x 1-3/4