Dealer service 21, Important – Woods Equipment RD6000-2 User Manual

Page 23

Dealer Service 21

MAN0180 (Rev. 1/7/2005)

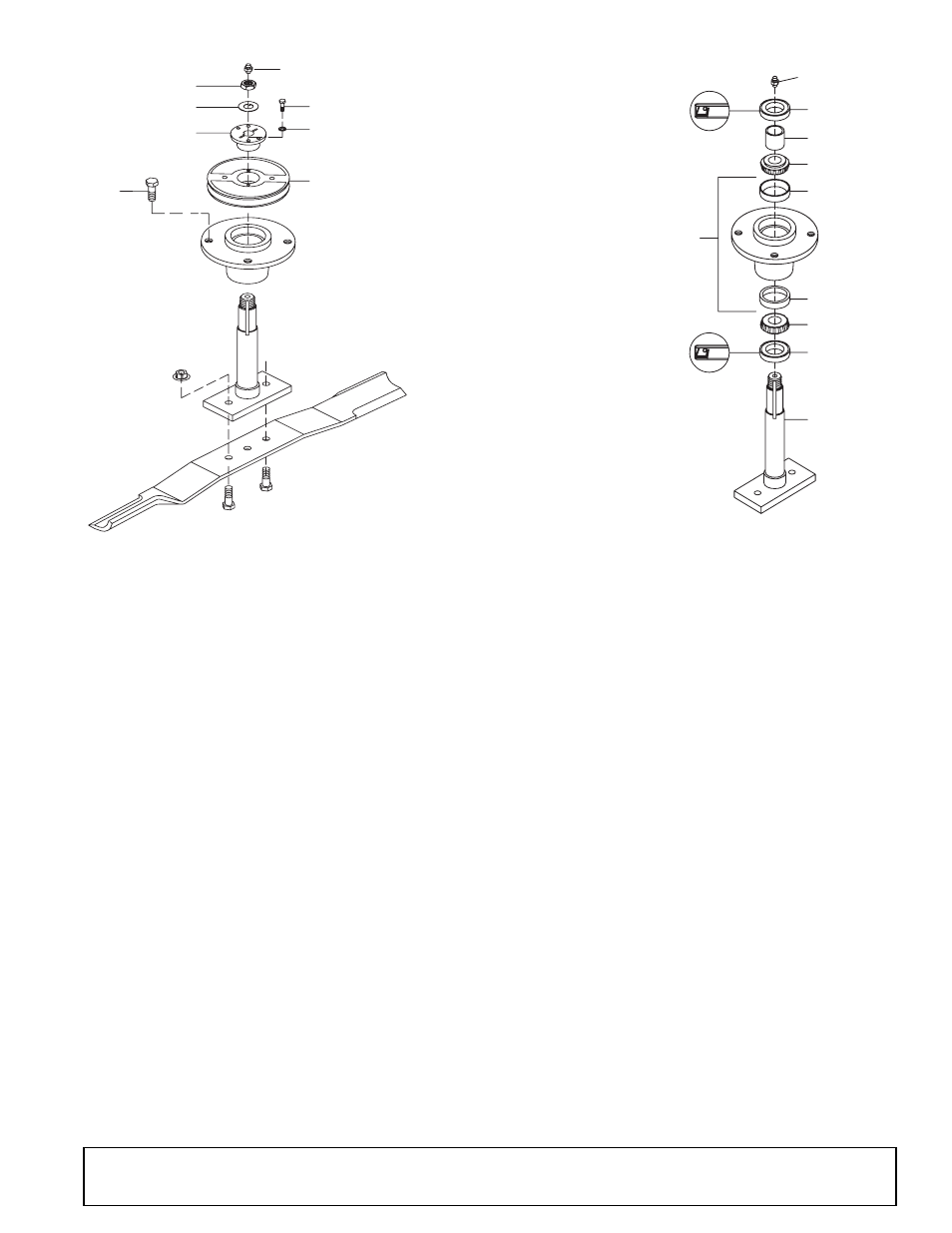

Figure 17. Sheave and Blade Assembly

Spindle Disassembly

1. Place spindle assembly in press and press shaft

down through housing.

2. Remove seals from housing.

Spindle Assembly

Refer to Figure 18.

Bearing cones and cups are designed to work together.

It is important to position them so bearing cone taper

mates with cup taper.

1. Lubricate new cups with a light oil. Place them in

spindle housing so they will mate with bearing

cones. Cups and cones are a press fit to minimize

wear.

Seat cups securely with a press or place a large

drift in the flat lip and drive them into housing until

cup seats against machined shoulder of housing.

Remove bearing cups from housing by placing a

punch in the slots provided and driving them out.

Alternate punch positions from side to side. Take

care to prevent housing damage.

2. Place bottom bearing cone into spindle with taper

positioned to mate with cup.

Figure 18. Spindle and Shaft Assembly

IMPORTANT

■

Improper positioning of seals can cause seal

damage. An improperly installed seal will leak and

could cause bearing failure.

3. Identify the open side of the seal containing the

spring.

4. Apply a thin coat of Permatex to the area of

housing where seals seat.

5. Install bottom seal with spring up toward center of

housing.

6. Place seal squarely on housing and select a piece

of pipe or tubing with an OD that will set on outside

edge of seal. A tubing with an OD that is too small

will bow seal cage.

7. Carefully press seal into housing, to prevent

distortion to metal seal cage. Bottom seal should

seat firmly and squarely against machined

shoulder in housing.

8. Make sure seal lip did not roll under. Distortion to

seal cage or damage to seal lip will cause seal to

leak. Damaged seals must be replaced.

9. Insert shaft and bearing through bottom of housing.

10. Fill housing cavity with a medium grade grease.

11. Install top bearing on shaft to mate with top cone.

3

1

6

5

4

2

CD5055-1

19

21

1. 7/8 NF Jam nut

2. 1/4 NC x 1 HHCS

GR5

3. .929 x 1.66 Lock

washer

4. 1/4 Lock washer

5. Bushing, H 1

straight bore w/key

6. Sheave, H 1 BK

19. 1/2 NF x 1-1/4

HHCS GR5

21.Grease fitting

2

1

2

3

4

5

4

5

7

6

Seal Lip

Seal Lip

CD5061

1. Grease fitting

2. Seal, 1.50 x 2.12 x .31

3. Sleeve, 1.14 x 1.50 x .55

4. Bearing, cone

5. Bearing, cup

6. Spindle, housing

7. Shaft, blade spindle