Torquemaster™ & i drive, Installation instructions insert – Wayne-Dalton IDRIVE 9900 User Manual

Page 2

®

Follow the corresponding steps in this insert with the steps in the installation manual provided with the door. These

modifications are designed to accommodate the new idrive™ garage door opener.

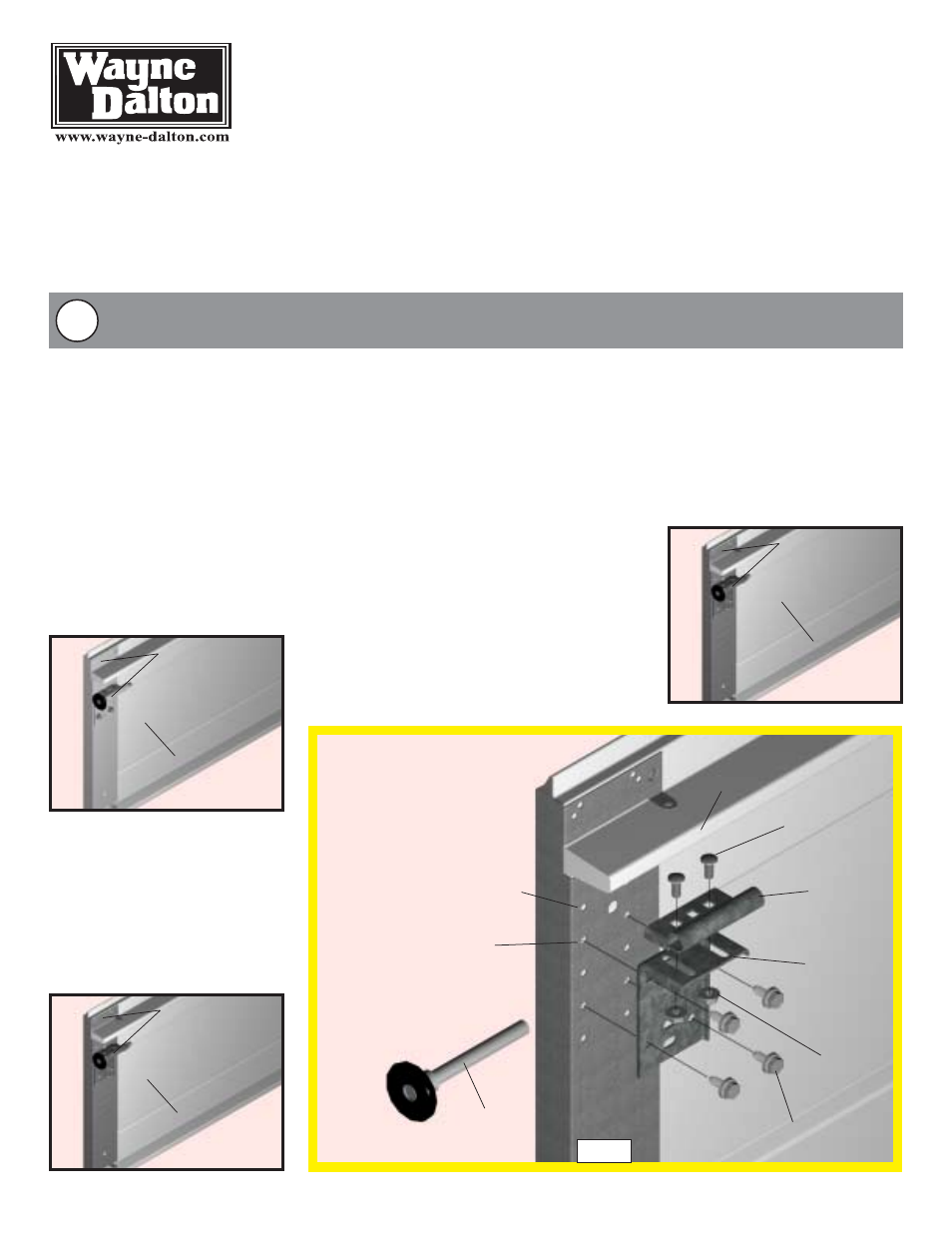

Top Bracket Installation

TOP SECTION

RIB

(2) CARRIAGE

BOLTS

TOP

BRACKET

TOP

BRACKET

SLIDE

3) 9200/9100 Foamcore™

(below) will have galvanized hard-

ware, with a laminated (soft) back-

ing on the sections.

(4) SELF-TAPPING

SCREWS

2

ND

SET OF HOLES ON

9600 THERMOGARD®

AND

9200/9100 FOAMCORE™

(2) HEX

NUTS

1

ST

SET OF HOLES ON

9900 THERMOWAYNE™

To install the L-shaped top brackets, align the top holes in the top bracket with the first set of holes in the endcap for 9900

Thermowayne™ doors and second set of holes for 9600 Thermogard

®

doors and 9200/9100 Foamcore™ doors. Fasten

using (4) 1/4-20 x 5/8” self tapping screws. Secure the top bracket slide to the bracket using

(2) 1/4-20 x 5/8” carriage bolts and nuts. Insert rollers. (see Fig. 1)

NOTE: To differentiate between a 9900 Thermowayne™, 9600 Thermogard® and 9200/9100 Foamcore™ door mod-

els, look for the following characteristics:

TorqueMaster™ & idrive™

9900 Thermowayne™

9600 Thermogard®

9200/9100 Foamcore™

INSTALLATION INSTRUCTIONS INSERT

ROLLER

1) 9900 Thermowayne™

(below) will have painted hard-

ware (top brackets, bottom brack-

ets, end caps, etc.) with a steel

backing on the sections.

2) 9600 Thermogard® (right)

will have galvanized hardware, with

a steel backing on the sections.

GALVANIZED

HARDWARE

STEEL

BACKING

GALVANIZED

HARDWARE

LAMINATED

(SOFT) BACKING

PAINTED

HARDWARE

STEEL BACKING

FIG. 1

2

8