Pump disassembly, Warning – Viking MAG DRIVE 855 User Manual

Page 7

SECTION TSM

685.2

ISSUE

C

PAGE 7 OF 16

6. Remove the idler and bushing assembly. If the idler

bushing needs to be replaced, see “

INSTALLATION

Of BUSHINGS” on page 10. If further disassembly is

required, the pump must be separated from coupling.

Refer to “

DISASSEMBLY Of COUPLING” on page 8

before proceeding with Step 7.

7. With the inner magnet removed, now remove the pump

shaft key. Remove the outer thrust washer. The rotor

and shaft may now be removed by tapping on the end of

the shaft with a soft face hammer (If a soft face hammer

is not available a regular hammer may be used with a

piece of hardwood).

8. Remove the inner thrust washer from behind the rotor.

The casing should be examined for wear, particularly in the

area between the ports. Clean all other parts thoroughly and

examine for wear or damage. Check the bushings, idler pin

and thrust washers; replace if necessary.

When making major repairs, such as replacing a rotor

and shaft, it is advisable to also install a new head and

idler pin, idler and bushing, and casing bushings. See

“

INSTALLATION Of BUSHINGS” on page 10.

PUMP DISASSEMBLY

1. To drain the liquid being pumped, remove the two (2)

drain plugs located in the bottom of the casing. Once the

liquid has drained replace the plugs.

2. Refer to figures 4, 6, 7 & 8 for names of parts.

3. Mark the head and casing before disassembly to insure

proper reassembly.

4. To inspect the head and pin assembly and idler and

bushing assembly, remove the head capscrews.

5. Remove the head from the pump. Do not allow the idler

to fall from the idler pin. Tilt the top of the pump head

back when removing to prevent this. Avoid damaging the

head shim set since all shims are required to maintain

end clearance.

WARNING!

Refer to DANGER & CAUTION listed on page 2

before proceeding.

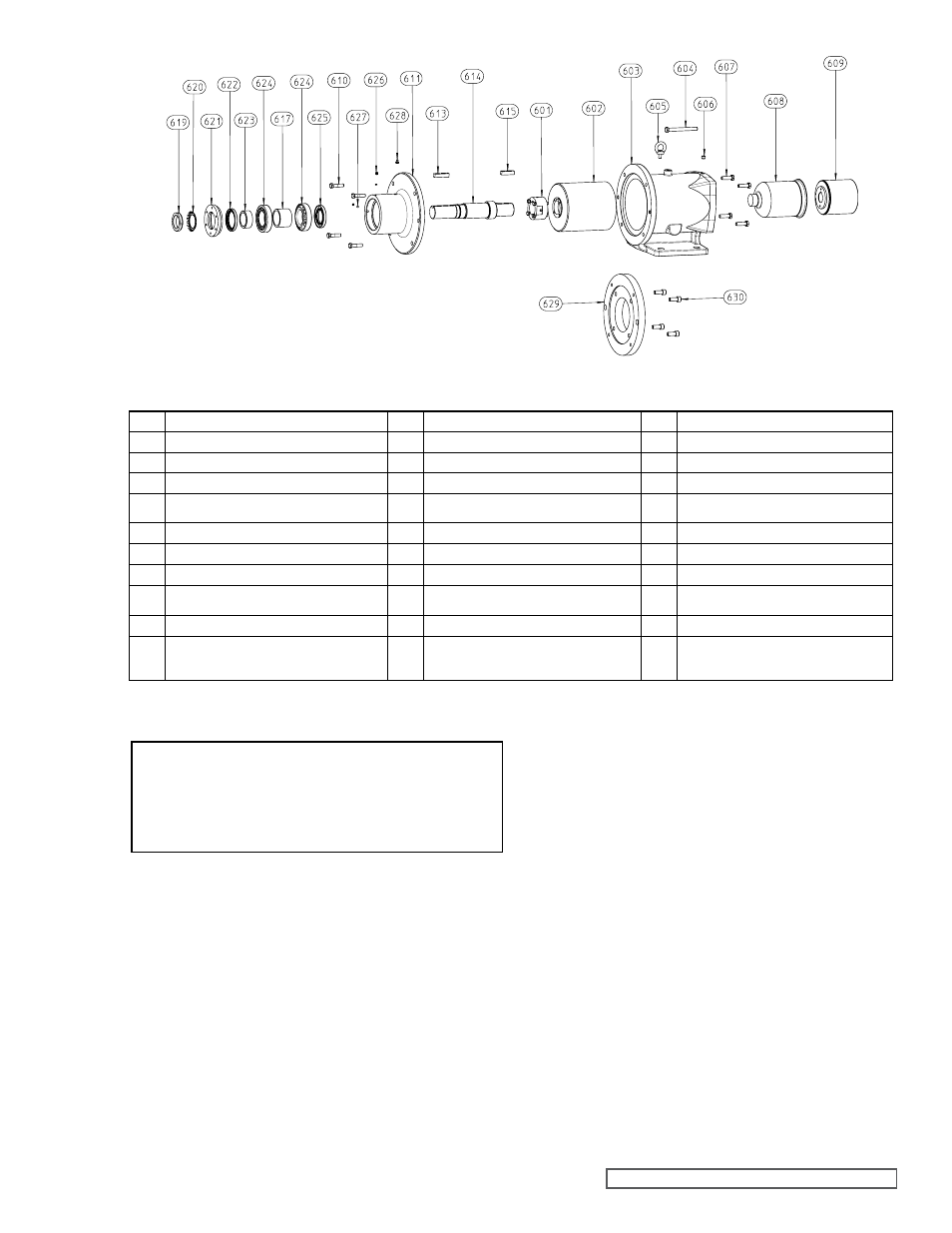

fIGURE 8

ITEM

DESCRIPTION

ITEM

DESCRIPTION

ITEM

DESCRIPTION

601 Bolt-on Hub with Hardware

611 Bearing Carrier Housing

623 Outer Bearing Spacer

602 Outer Magnet Assembly

613 Drive Key - Outboard Side

624 Tapered Roller Bearing - 2 Req’d

603 Bracket

614 Shaft

625 Lip Seal (Inner)

604 Capscrew (jackscrew) for Disassembly

(metric)

615 Drive Key - Inboard Side

626 Setscrew - 2 Req’d

605 Lifting Eye

617 Inner Bearing Spacer

627 Insert - 2 Req’d

606 Pipe Plug for Sensor Hole

619 Locknut

628 Grease Fitting

607 Capscrews (metric) for Pump - 4 Req’d 620 Lockwasher

629 Adapter (NEMA motor only)

608 Canister and Bushing Assembly

621 End Cap

630 Capscrews (metric) for Adaptor - 4

Required

609 Inner Magnet Assembly

622 Lip Seal (Outer)

610

Capscrews (metric) for Motor or

Bearing Carrier - 4 Req’d (284 Motor

Frame, - 5 req’d)

M DRIVE CONfIGURATION

MD2- C SERIES COUPLING AND BEARING CARRIER COMPONENTS

TABLE 5